Packaged Beverage Analyzer:

PBA 5001 Soft Drink

- Simultaneous determination of °Brix and CO₂ content

- Results are more than 6x quicker than with conventional methods

- Modular setup: 10+ industry-specific parameters

- Zero influence from dissolved CO₂ on °Brix results

- Analysis of the finished package: zero operator influence

Get results for °Brix and CO₂ content in three minutes and for %Diet in six minutes. This is up to 6x faster than conventional methods. The Packaged Beverage Analyzers combine up to four instruments to determine all quality parameters for regular, mid-calorie, and diet soft drinks as well as (diet) energy drinks and carbonated bottled water in one go. There’s zero prior preparation or intermittent cleaning, which saves you up to two hours a day. This fast quality control for soft drinks helps you optimize your blending process, ensures ideal carbonation levels, and guarantees confidence in the final bottled product.

Key features

Here you have a single system, configured according to your individual needs, controlling all relevant parameters for soft drink quality. Simply put the final package in the filling device, and the sample is filled automatically under pressure – no chance for contamination or operator influence. The system is operated via a single intuitive user interface, and all data is stored safely, either on the instrument or in a single digital space via AP Connect, our lab execution software.

All quality control tests for soft drinks in one go

- Determine %Diet, °Brix, and CO₂ concentration with a single system in a single measuring cycle

- Analyze your entire soft drink portfolio, including regular, mid-calorie, and diet soft drinks, energy drinks, and carbonated water

- Reduce reference analysis for diet products to an absolute minimum, to free up lab capacities

- Safeguard final product quality and do away with out-of-spec production

Speed up soft drink quality control by 600 %

- Parallel analysis of all parameters in only three to six minutes (depending on system configuration) – more than 6x faster than conventional methods

- Automatic pressurized filling directly from glass bottles, PET bottles, and cans: zero operator influence

- Save up to seven minutes per sample for degassing and filtration

- No degassing required: Benefit from automatic CO₂ correction of all measurement results

- Software-guided adjustment procedure lets anyone manage quality control of diet products – no special training required

Set up your individual measuring system

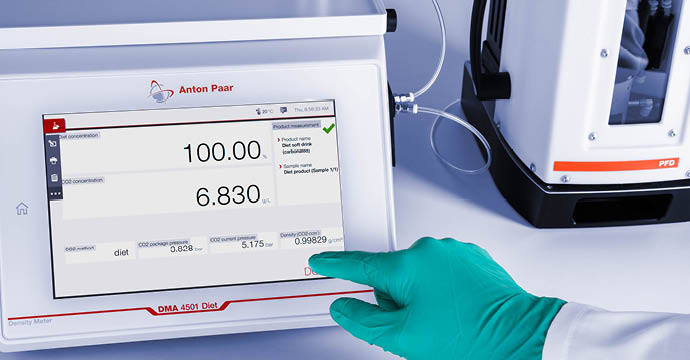

- In its basic version, PBA 5001 Soft Drink determines the three most important soft drink parameters: °Brix, CO₂ concentration, and density

- For determination of %Diet, the system is simply configured with a different master instrument

- To perfect your analysis, upgrade your basic system with modular extensions for measurement of dissolved O₂ and pH

- Increase system efficiency and confidence in your final product quality with every module added

Determine the true amount of dissolved CO₂ in soft drinks

- Unique selective CO₂ measuring method delivers supreme repeatability of 0.005 vol.

- Pin-point accuracy: Determine the true amount of CO₂

- No influence by other dissolved gases such as air or nitrogen

- Automatic filling error detection for the density and CO₂ measuring cell leaves no chance for errors

Intuitive usability for maximum convenience

- Simultaneous operation of all connected measuring modules through a single user interface

- Minimal training: Built-in wizards guide operators through measuring and adjustment steps

- Wide range of preconfigured output quantities

- Adaptable user interface for maximum operator convenience

- Centralized data management via AP Connect lab execution software

- Automated adjustment of inline sensors via Davis 5 software – no need for manual operator interaction

Technical specifications

| PBA 5001 Soft Drink | PBA 5001 Diet Soft Drink | |

|---|---|---|

| Measuring range | ||

| Density | 0 g/cm³ to 3 g/cm³ | |

| Temperature | 20 °C | |

| Pressure | Up to 10 bar (145 psi) absolute pressure | |

| Concentration sugar actual | 0 °Brix to 15 °Brix | |

| Diet concentration | - | 0 to 200 % Diet or 0 to 200 mL NaOH or 0 to 200 g/L TA or 10 to 10,000 ppm Alkalinity or 0 to 600 mg/100 mL H3PO4 |

| CO₂ concentration | 0 vol. to 6 vol. (0 g/L to 12 g/L) at 30 °C (86 °F) | |

| O₂ concentration | 0 ppm to 4 ppm | |

| pH value | pH 0 to pH 14 | |

| Repeatability s.d. | ||

| Density | 0.00001 g/cm³ (DMA 4101) | 0.000005 g/cm³ (DMA 4501 Diet) |

| Temperature | 0.02 °C (0.04 °F) (DMA 4101) | 0.01 °C (0.02 °F) (DMA 4501 Diet) |

| Concentration sugar actual | 0.015 °Brix (DMA 4101) | 0.01 °Brix (DMA 4501 Diet) |

| Diet concentration | - | 0.5 %Diet |

| CO₂ concentration | 0.005 vol. (0.01 g/L) | |

| O₂ concentration | 2 ppb (in the range <200 ppb) | |

| pH value | 0.02 (in the range pH 3 to pH 7) | |

| General information | ||

| Power features | U-View™, FillingCheck™, ThermoBalance™, full-range viscosity, correction, ultra-fast measuring mode, condition monitoring | |

| Minimum amount of sample per measurement | 150 mL | |

| Typical measuring time per sample | 3 minutes (6 minutes for %Diet analysis) | |

| Typical sample throughput | 10 to 20 samples per hour, depending on system configuration | |

| Display | 10.1" TFT WXGA (1280 px x 800 px); PCAP touchscreen | |

| Controls | Touchscreen, optional keyboard, mouse, and bar code reader | |

| Internal storage | Up to 10,000 measuring values with camera images | |

| Power supply | AC 100 to 240 V, 50/60 Hz, fluctuation ±10 %, 190 VA | |

| Communication interfaces | 5 x USB, Ethernet, CAN, RS232 | |

| Dimensions (L x W x H) | 526 mm x 730 mm x 446 mm (20.7 in x 28.7 in x 17.6 in) | |

| Weight | Approx. 35.7 kg (77 lbs) | |

| Environmental conditions | (EN 61010) Indoor use only | |

| Ambient temperature | 15 °C to 35 °C (59 °F to 95 °F) | |

| Air humidity | Non-condensing 20 °C, <90 % relative humidity 25 °C, <60 % relative humidity 30 °C, <45 % relative humidity | |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Soft Drink Analysis Overview Brochure Brochures

-

Three Factors That Affect Production Value Targets (drinkworld Nov 2022) Customer Reports and Publications

-

DMA 4501 Diet Reference Guide Manuals

-

PBA 5001 Soft Drink Diet SOP Manuals

Similar products

Consumables & Software

Consumables & Software

Software

Software

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

Interface caps DMA HR01 series

PBA 5001 Soft Drink Standard | Diet