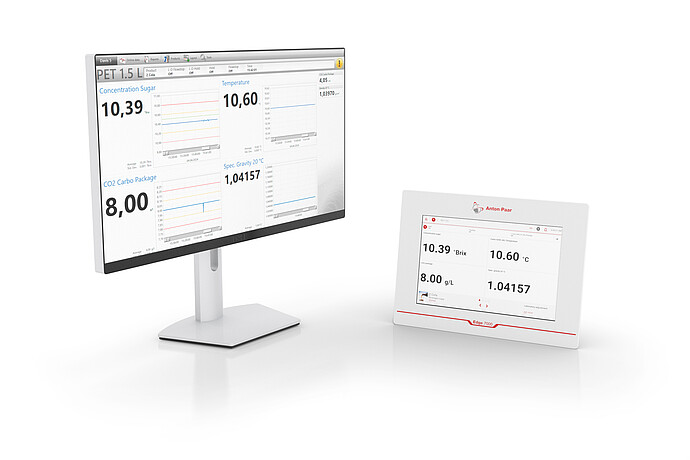

Process Controllers and Analysis Software

Expand control, with visualization and reporting

We channel 40 years of experience in inline and laboratory beverage analysis to position you one step ahead of your competitors. Connect Anton Paar’s versatile process controllers to all generations of Anton Paar density, sound velocity, concentration and CO2 sensors. The data acquisition and visualization software will master even the most complex measuring tasks for you with renowned Anton Paar measurement precision.

Anton Paar Products

Easy to operate

Connect to PCs throughout your organization via Ethernet: Davis 5 ensures seamless integration. Based on an open client/server architecture, the system stores production data on your server and enables simultaneous display on multiple PCs throughout your enterprise network. View an active window showing real-time values and graphical trends on remote screens anywhere on your site.

Product-specific settings optimize safety

You can easily specify production settings, limits and alerts for individual products. Whenever measured values fall out of spec, screen color changes or audible signals quickly alert your team. Brand-specific settings, including target values and alarm limits, can be programmed for up to 999 beverages. Your team also benefits from the creation and management of a perfectly maintained products database.

Eliminate human error

Davis 5 helps you save time during routine operations by automatically comparing process results with laboratory reference values. The system’s calibration and adjustment are user-friendly and integrated with an automatic analysis function that eliminates human error. You can easily recognize drifts and other process inefficiencies and correct them on the fly.

Keep track of your processes

View initial values while the system continues to collect and store data. Monitor production runs from any office in the plant. Starts/stops, out-of-range values, trends, mean value, min./max., standard deviation, operating times, line downtimes, bottle/can numbers, history of adjustments and quality data (Cp, Cpk and Quality Index, etc.) can be monitored, viewed, e-mailed, downloaded, or printed.

Powerful reporting

Davis 5 automates report generation according to your requirements. Transfer data to a LIMS or send e-reports to a smartphone, tablet or PC. View statistical reports in XML or PDF formats so they are easily readable by your corporate quality management system. The reports are accessible after each batch is run or at any time that is convenient for you.

Webinars

We offer you a great and constantly growing choice of live webinars and recordings on products, applications, and scientific topics.

Show more