Digital density

measurement

redefined

After more than 50 years of incremental

improvements, Anton Paar redefines digital

density measurement and shapes the

future of the technique once again.

Density Measurement Redefined

In 2015, a density task force was initiated resulting in implementation of a unique measuring method in 2018: the Pulsed Excitation Method (PEM).

- 2x better viscosity correction than predecessor

- Best FillingCheck™ ever

- 8 new patents

- Numerous add-on features

The Next-Level Density Meter

to 4-digit accuracy,

6-digit accuracy available

guided

user workflows

user experience

ever

industry-specific software

1960s

Digital density measurement invented by

Prof. Otto Kratky

1967

First digital density meter built and presented by Anton Paar

1988

Viscosity compensation of density results

A new

heart,

a new

start

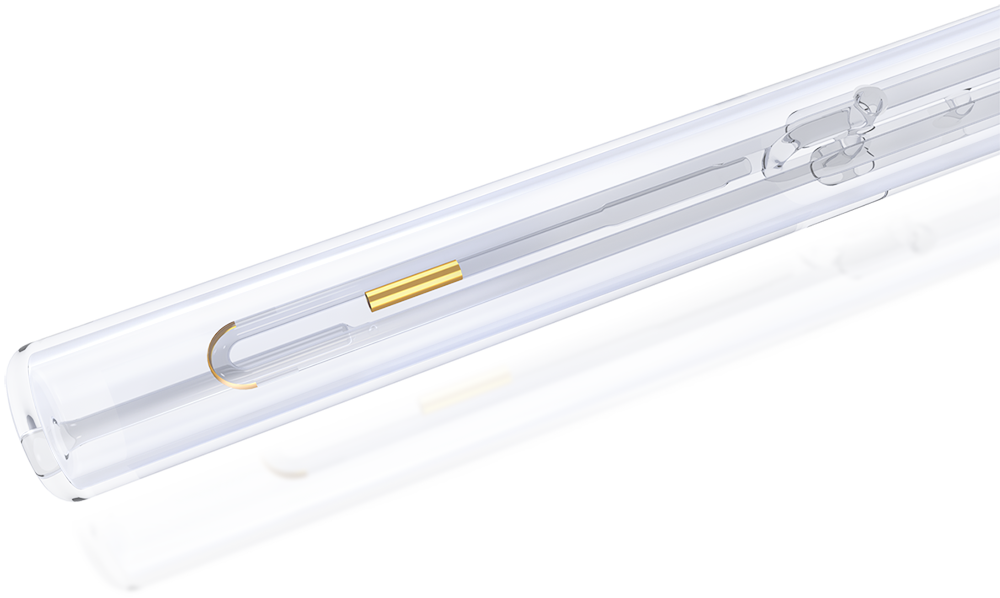

The heart of a modern digital density meter is the measuring sensor, a U-shaped tube made from borosilicate glass or metal. It is excited to oscillate at its characteristic frequency, which is directly related to the density of the sample. After Anton Paar’s re-invention of digital density measurement, there are now two excitation methods on the market: conventional and new.

viscosity

correction

Forced

Oscillation

Method

Reached its limits

Used in conventional density meters

Since the launch of this method by Anton Paar in the 1960s, a constant oscillation of the U-tube has been the state of the art. In this method, the U-tube is forced to oscillate continuously at its characteristic frequency. Over the years, continuous improvements like viscosity correction of the measured results and filling error detection were implemented. However, this technology has reached its limits. In order to advance, Anton Paar’s dedicated research team has rethought this technology from scratch.

Pulsed

Excitation

Method

Highest precision up to the 7th digit

2x better viscosity correction

Patented technology exclusively by Anton Paar (Patent AT 516420 B1)

The new patented Pulsed Excitation Method (PEM) redefines digital density measurement. After reaching a stable oscillation, the excitation is switched off and the oscillation fades out freely. This sequence of excitation and fade-out is repeated continuously, creating a pulsing oscillation pattern. By allowing the natural oscillation of the U-tube, and evaluating this oscillation pattern, the instrument gains three times more information than with the conventional Forced Oscillation Method.

Your benefits:

The highest precision

Viscosity insight

More confidence

FillingCheck™ for metal oscillators

Forced

Oscillation

Method

Reached its limits

Used in conventional density meters

Since the launch of this method by Anton Paar in the 1960s, a constant oscillation of the U-tube has been the state of the art. In this method, the U-tube is forced to oscillate continuously at its characteristic frequency. Over the years, continuous improvements like viscosity correction of the measured results and filling error detection were implemented. However, this technology has reached its limits. In order to advance, Anton Paar’s dedicated research team has rethought this technology from scratch. The result: The new patented Pulsed Excitation Method.

Clearly

the better way

water

adjustment

Clearly

the better way

Benchtop density meters make use of U-tube technology with two different types of oscillation directions, X and Y, named after their physical movement. Over time, the X-oscillator proved to have technological limitations.

| X-oscillator | Y-oscillator | |||

| Straight parts moving towards each other | Oscillation direction | Bend of the U-tube moving up and down | ||

| Limited accuracy for viscous samples | Viscosity influence | No limitations over the full range | ||

| High error rate with inhomogeneous samples or in case of particles and bubbles | Sample condition | Particles and bubbles are detected reliably | ||

| Accuracy limited to 0.001 g/cm³ | Measurement performance | Accuracy up to 0.000007 g/cm³ | ||

|

|

||||

As the technology leader, we always go for the better way. This makes the decision obvious: For the highest precision, only Y-oscillators are used in Anton Paar benchtop density meters.

More than

50 years of

experience

in your hand

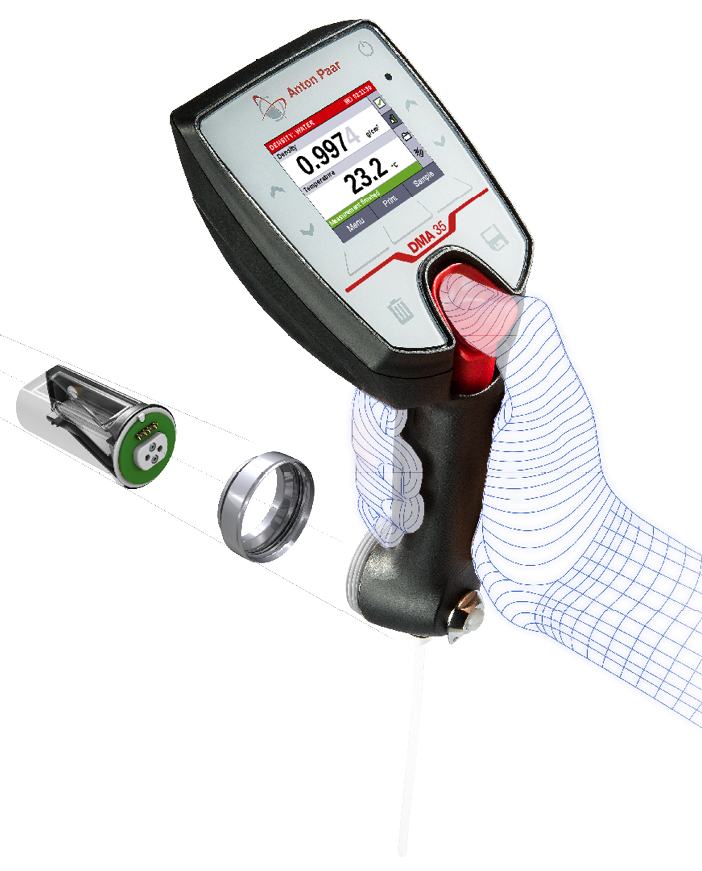

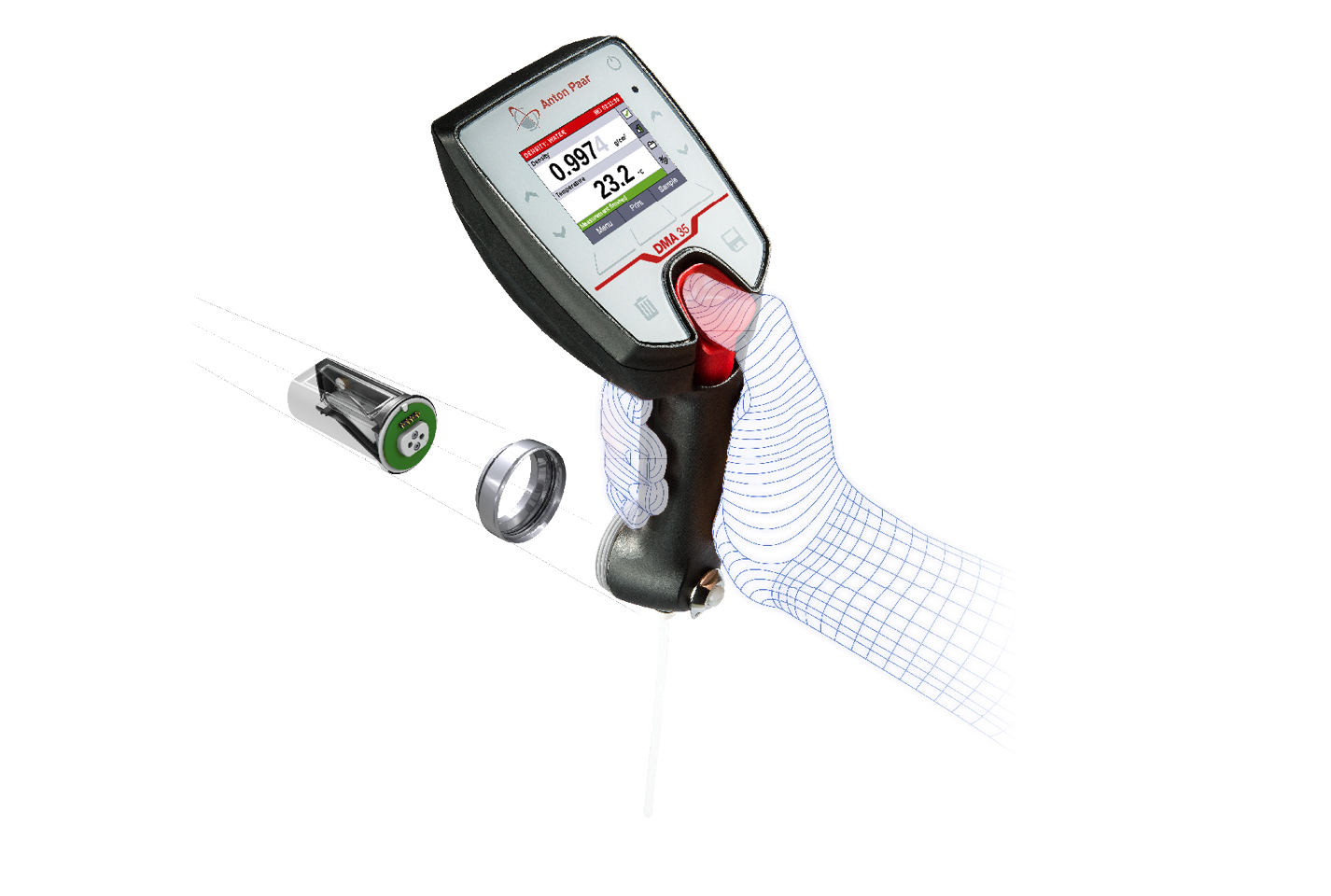

Only intrinsically safe device

Only intrinsically safe device

Anton Paar provides a range of portable density meters, including the only intrinsically safe handheld device.

Only intrinsically safe device

Only intrinsically safe device

Free webinar recordings

Go digital – entry to a new and more convenient world

3-year warranty

- Effective January 1, 2020, all new Anton Paar instruments* include repair for 3 years.

- Customers avoid unforeseen costs and can always rely on their instrument.

- Alongside the warranty there is a wide range of additional services and maintenance options available.

* Due to the technology they use, some instruments require maintenance according to a maintenance schedule. Complying with the maintenance schedule is a prerequisite for the 3-year warranty.

The

broadest portfolio

for laboratories and

production sites

Today’s world requires combined solutions and standardization across departments, plants, and subsidiaries. Anton Paar meets this demand with the broadest portfolio of density meters available: from the only intrinsically safe handheld density meter on the market to the most accurate benchtop density meter.

But the portfolio does not end there: Numerous sample changers allow you to process up to 96 samples in a row fully automatically, including a heated sample changer for measurements at up to 90 °C.

For the ultimate fusion of your laboratory and production plant, Anton Paar inline sensors measure density, Brix, concentration, API gravity, and other parameters and communicate with the benchtop DMA density meters via our matchmaking features. This connection guarantees correct density results in the lab and at the production line at all times.

Browse process density sensors

Anton Paar density meters are ready wherever high-end density and concentration measurement are needed – across all industries and applications.

The

broadest portfolio

for laboratories and

production sites