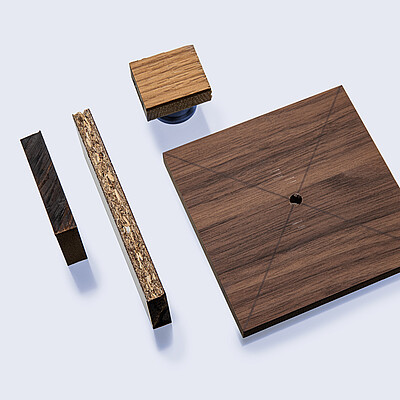

Wood Testing Solutions for Building Materials and Construction

Wood testing is essential for developing and maintaining the quality, strength, and durability of building materials. Accurate analysis of wood properties, adhesives, and coatings ensures products meet industry standards and perform reliably in real-world construction environments.

Reliable measurement methods support innovation, optimize material formulations, and help manufacturers deliver consistent results across all types of wood-based building applications.

Why invest in advanced wood testing solutions?

Accurate and repeatable measurement techniques tailored to wood are essential. Whether working with solid timber, engineered wood products, or composite materials, precise testing enables early detection of property changes, ensures adhesive and coating compatibility, and verifies strength and durability under real-world conditions. These insights empower manufacturers to refine formulations, enhance production processes, and support innovation in wood-based construction solutions.

- Consistent, accurate data: Reliable measurement for wood testing in building materials and construction

- Early detection of variations: Identify changes in wood properties, adhesive performance, and coating quality

- Production optimization: Use detailed measurement data to improve material performance and manufacturing efficiency

- Supports material innovation: Equip your R&D with tools for advanced wood analysis and product development

The Must-Read Anton Paar E-Book on Building Materials

Learn how to enhance the performance and reliability of wood-based building materials with Anton Paar’s free e-book, A Practical Guide for Great Building Materials. Exploring a wide range of topics across the construction materials industry, the guide includes a dedicated section on wood, covering topics such as humidity effects on adhesives, scratch resistance of self-healing coatings, and surface charge analysis for wood and cellulose. It is ideal for engineers, researchers, and quality professionals working to meet industry standards and advance wood construction technologies.

Learn how to enhance the performance and reliability of wood-based building materials with Anton Paar’s free e-book, A Practical Guide for Great Building Materials. Exploring a wide range of topics across the construction materials industry, the guide includes a dedicated section on wood, covering topics such as humidity effects on adhesives, scratch resistance of self-healing coatings, and surface charge analysis for wood and cellulose. It is ideal for engineers, researchers, and quality professionals working to meet industry standards and advance wood construction technologies.

Explore our instrument solutions

Whether you need to evaluate adhesive performance under humidity, analyze the scratch resistance of wood coatings, or determine the surface properties of wood and cellulose fibers, our instruments deliver accurate and actionable results for research, quality assurance, and product development.

Humidity-dependent adhesive testing in wood construction

Precisely measure how humidity impacts the mechanical properties of adhesives used in wood construction. Our solutions enable:

- Characterization of tensile elastic modulus under different humidity levels, ensuring adhesives maintain structural integrity in varying environments

- Rapid, climate-controlled testing methods that deliver reliable data for optimizing adhesive formulations and improving durability

- Support for quality control processes by enabling manufacturers to adapt adhesives to changing environmental conditions

Scratch resistance and recovery of wood coatings

Assess the scratch resistance and elastic recovery of self-healing and conventional paints on wood surfaces. Key features include:

- Progressive load scratch testing to quantify surface durability and resistance to mechanical damage

- Instrumented indentation for detailed mechanical property profiles, supporting the selection of advanced, longer-lasting coatings

- Comparative analysis of conventional and self-healing paints to ensure superior protection and reduced maintenance

Surface charge determination of wood

Evaluate the zeta potential and surface functional group density of wood, pulp, and cellulose fibers. Our solutions provide:

- Insights into surface hydrophilicity, swelling behavior, and compatibility with adhesives or coatings

- The ability to monitor and optimize wood surface modifications for improved performance in composites and engineered wood products

- Reliable measurement techniques for supporting R&D and quality assurance in wood material development

Industries and use cases

Anton Paar’s wood testing solutions are used throughout the building materials sector, helping manufacturers and engineers ensure high performance and compliance in modern construction projects. Key applications include:

- Structural wood components: Testing adhesives and surface treatments for beams, panels, and engineered wood products to meet strength and safety requirements

- Wood coatings and finishes: Evaluating the scratch resistance, durability, and self-healing properties of coatings for flooring, cladding, and interior surfaces

- Insulation and composite materials: Characterizing surface charge and compatibility of wood fibers and cellulose in insulation boards, lightweight panels, and composite materials

- Quality control and R&D: Supporting product development and process optimization for all types of wood-based materials used in the construction industry

These solutions ensure consistent quality, improved durability, and innovation across a wide range of wood applications in building and construction.

Why choose Anton Paar?

- Industry expertise: Decades of experience in material characterization for wood and building materials

- Reliable, accurate results: Instruments engineered for precise, repeatable wood testing in research and quality control

- Comprehensive solutions: Technologies for adhesive evaluation, coating analysis, and surface property determination

- Global support network: Application specialists and technical support available worldwide

- Trusted by leading manufacturers: Proven track record with building material producers, research institutes, and industry partners.

Questions or looking for more information? Contact our team for expert support.