Analysis of asphalt and bitumen and their additives at the refinery ensures that they meet the specifications. Anton Paar’s measuring instruments and dedicated asphalt testing solutions deliver valuable insights into material properties which affect processing of your asphalt and bitumen, such as long-term stability and consistency, as well as behavior in storage and during transportation. The right measuring instruments optimize your products so they withstand all environmental conditions.

Get Our Latest Bitumen Rheology Book

Interested in learning more about the flow and deformation behavior of bitumen in an easy, entertaining way? Then join Joe Flow and Samira Smart on the Bitumen Rheology Road.

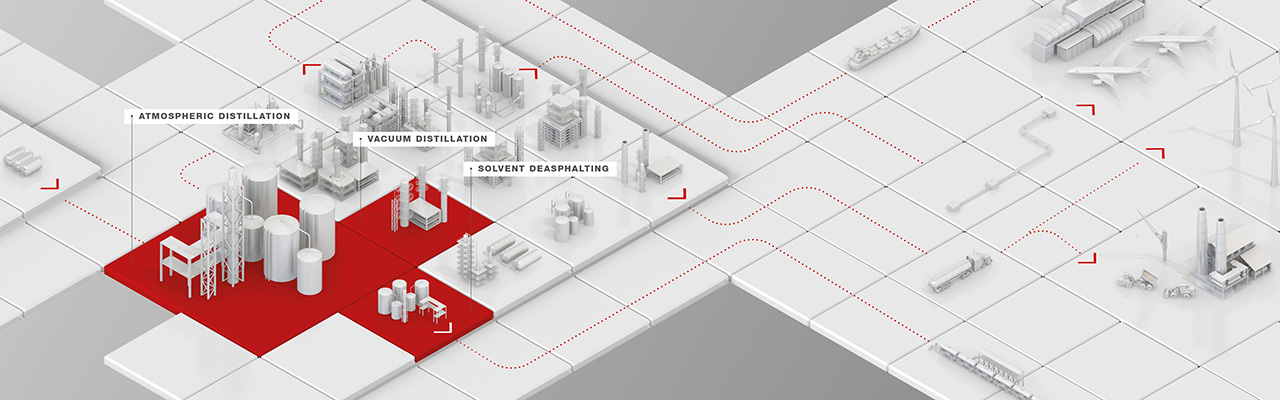

Asphalt and bitumen analysis at refineries

Producing durable asphalt and bitumen products requires analysis of material properties in quality control and during development. Anton Paar’s measuring devices help you fine-tune the elasticity of your asphalt/bitumen products through analysis of the additives. Results from our measuring instruments form the basis for evaluation of the deformation and flow behavior of asphalt/bitumen compositions. We also provide solutions for determining parameters such as penetration and breaking points in order to assess consistency. And our asphalt testing equipment helps you to develop bitumen emulsions which meet design specifications and performance criteria, and supports you in certifying asphalt binders according to standards. The instruments take work off your hands with built-in automation and simple measuring routines. They also allow sample preparation for elemental analysis to ensure your asphalt and bitumen are of top quality and have the correct properties.

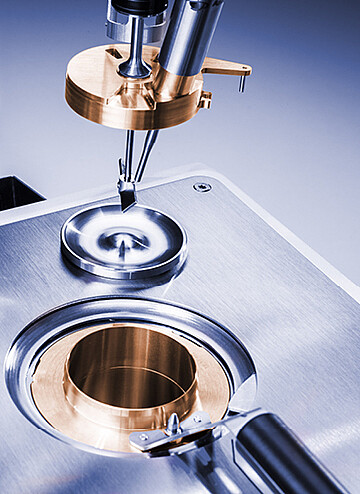

Performing temperature calibration at regular intervals to ensure constant measurements

Developing bitumen emulsions to meet design specifications and performance criteria

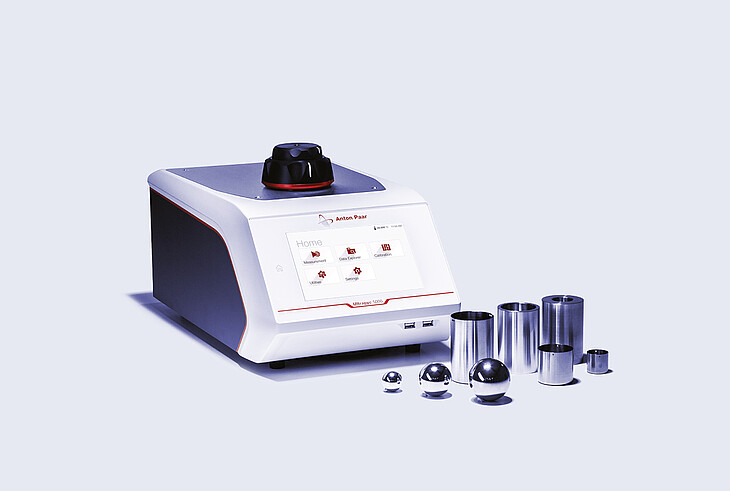

Accurately measuring and matching the density of bituminous semi-solids, asphalt binders, and mixtures with paving requirements

Determining the viscosity of asphalt binders to assure pumpability, mixability, and processability in compliance with ASTM or AASHTO

Asphalt and bitumen testing during distribution

Anton Paar’s measuring technology delivers meaningful insights into the long-term stability of your asphalt/bitumen, and permits smooth storage and transportation. Our portable and lab devices help you calculate asphalt/bitumen mass from a known volume for account settlement. Our instruments guarantee fulfilment of all international standards for asphalt mixtures and binders testing, and ensure compliance with fire safety regulations and product specifications. They also support regular measurement of the rheological properties of asphalt binders.

Asphalt and bitumen analysis for consumers

The asphalt and bitumen industry has undergone significant advancements, resulting in elevated quality standards and increased consumer demand for optimal product performance. To meet these needs, Anton Paar provides innovative asphalt testing solutions. Our products strictly adhere to all relevant international standards and help you satisfy fire safety regulations, and product specifications, guaranteeing the seamless processing of asphalt and bitumen. Whether you're paving roads or constructing buildings, our equipment assists you in the processing of asphalt products that ensure top-notch quality and desirable features. With Anton Paar, you can rely on your asphalt and bitumen products meeting the highest standards of excellence.

Asphalt and bitumen analysis at testing labs

In the field of asphalt and bitumen testing, testing labs have faced a significant increase in demands in recent years. The industry now upholds extremely high quality standards, and customers have raised their expectations for high-performance testing equipment to guarantee their products satisfy these standards. Anton Paar's complete asphalt testing solutions ensure adherence to international standards, fire safety regulations, and product specifications, allowing for efficient further processing. To cater to the diverse requirements of both customers and testing labs, we provide a range of advanced measuring solutions.

Performing temperature calibration at regular intervals to ensure constant measurements

Receiving new DSR software protocols after release of country-specific standards updates for bitumen testing

Increasing sample throughput when measuring density and specific gravity of bitumen and asphalt binders for mass-to-volume conversion

Sample preparation for elemental analysis, asphalt / bitumen quality and properties assurance

Viscosity analysis of asphalt and bitumen samples at different temperatures, with the benefit of fast heating and cooling rates

How to quickly evaluate the performance of bitumen emulsions: measuring particle size and zeta potential