Multiparameter Measurement System:

Turbidity Measurement System

- Single filling cycle for density and turbidity parameters

- Turbidity analysis using proven ratio method for all particle sizes

- Automatic filling with minimum sample volume

- Full traceability, including user-management and audit trail

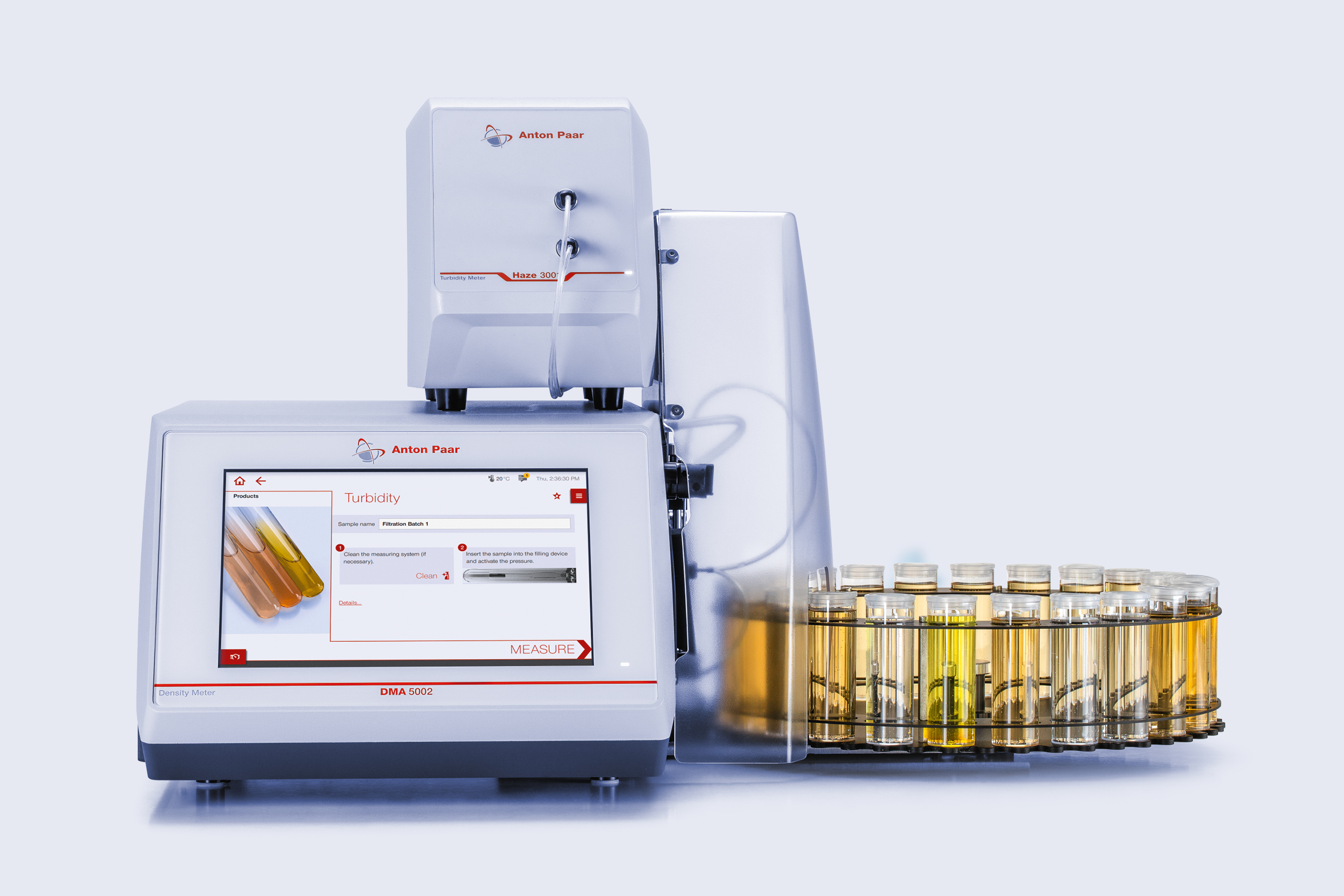

Density, specific gravity, and turbidity measurement from a single filling cycle – the Turbidity Measurement System combines two key parameters for injectables, infusions, vaccines, biopharmaceuticals, and liquid formulations. Featuring a robust, fully enclosed turbidity measuring module, it requires minimal sample volumes while supporting a variety of filling options. Accurate temperature control ensures the best results possible in the shortest time, and superior software features for regulated industries ensure complete traceability.

Included products

Key features

Your key parameters from a single sample

Most liquid pharmaceutical formulations, chemicals, or flavor and fragrance compounds must be clear. Opalescence-inducing particles can indicate contamination or even an unsafe product. The Turbidity Measurement System helps you monitor the filtration and cleaning processes, as well as factors like protein aggregation, while simultaneously measuring the sample’s density.

Both parameters are measured in one sample filling. The measurement is controlled by the density meter, and the results are instantly combined in one data set.

Minimal sample volume required

Avoid wasting precious sample liquid when filling standard measuring cuvettes and high-volume glass pycnometers or hydrometers. The Turbidity Measurement System facilitates reliable measurements with as little as 3 mL of sample volume for a single turbidity measurement when injected directly at the Haze 3001 module, or as little as 5 mL for a combined density and turbidity measurement.

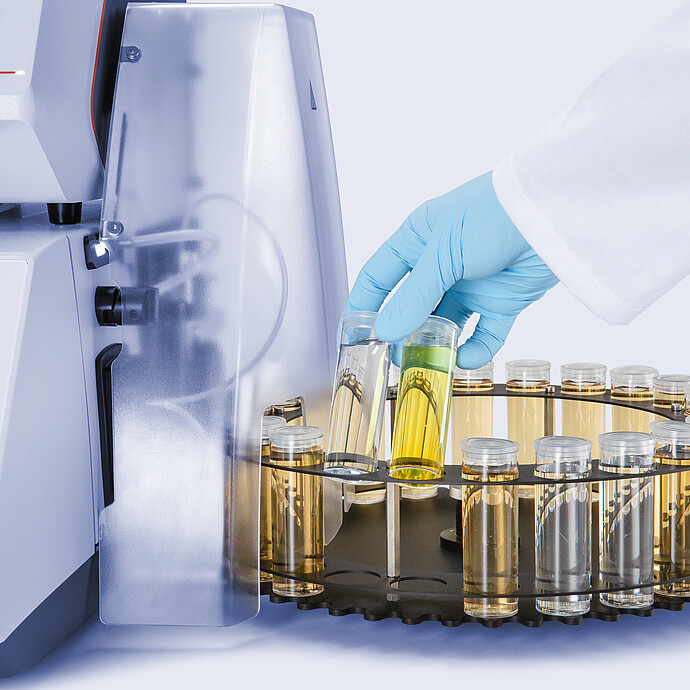

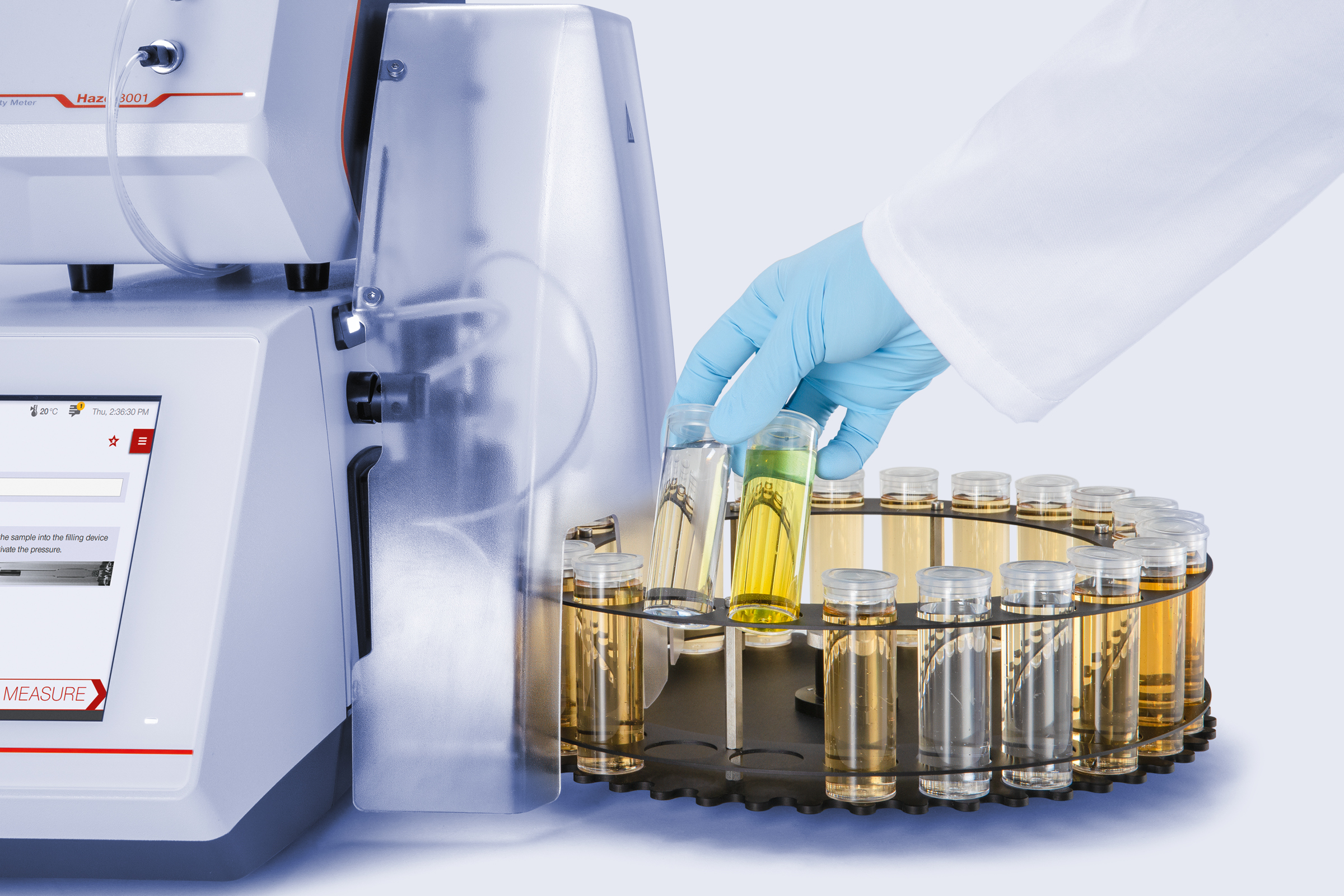

Automation tailored to your requirements

There's a filling solution for every requirement – whether it relates to sample throughput, sample properties, or necessary safety measures. With the automatic sample changer, you can efficiently fill and measure a day’s workload of samples – freeing up time for other laboratory tasks. For a quick determination of a single measuring parameter, simply fill the specific measuring module directly with a syringe to minimize sample consumption. A single sample changer enables safe handling of dangerous substances like aggressive chemicals or biologically active pharmaceuticals.

No complex handling of cuvettes for turbidity measurements

Regular turbidity meters require intensive maintenance of glass cuvettes – including thorough cleaning, regular calibrations, and marking for the best orientation in the measuring cell. Scratching must be avoided and the cuvettes must be wiped with silicone oil to minimize light distortion and ensure accuracy. The Haze 3001 turbidity module eliminates these inconveniences, thanks to its robust, completely enclosed measuring cell and setup. Simple flow-through filling is all that’s needed.

Accurate temperature control safeguards precision

Sample temperature is a factor that significantly affects density and turbidity values. The Turbidity Measurement System’s measuring modules feature best-in-class Peltier-based temperature control – enabling fast temperature equilibration of the sample as well as perfect control of the measuring conditions. Continuous reproducible results are guaranteed.

Complete traceability and data handling

In accordance with GMP guidelines, regulated industries must document all actions on laboratory instruments. The Turbidity Measurement System offers superior compliance features such as user management, audit trail, and electronic signature with review and approval functionality – eliminating any uncertainty about your results. Control your instruments directly from your computer via a network connection, and use our lab execution software, AP Connect, to collect, review, and organize your measurement data. Industry-specific instrument qualification packages and expert service support minimize the time it takes to integrate your Turbidity Measurement System into your daily workflow and operational processes.

Standards

European Pharmacopoeia (Ph. Eur.)

US Pharmacopoeia (USP)

Japanese Pharmacopoeia (JP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty