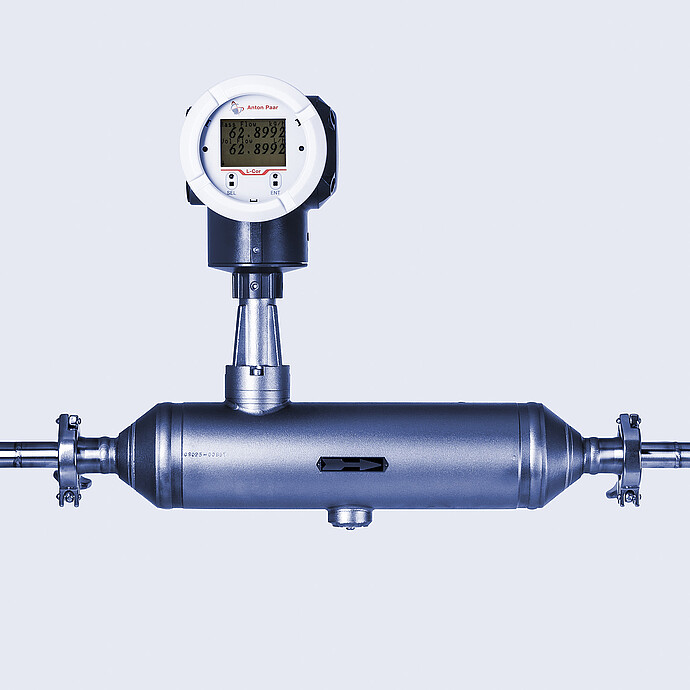

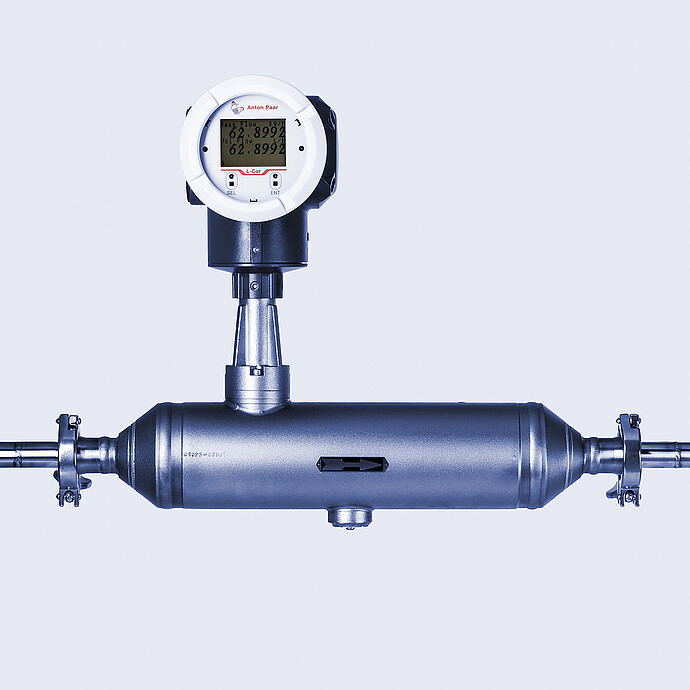

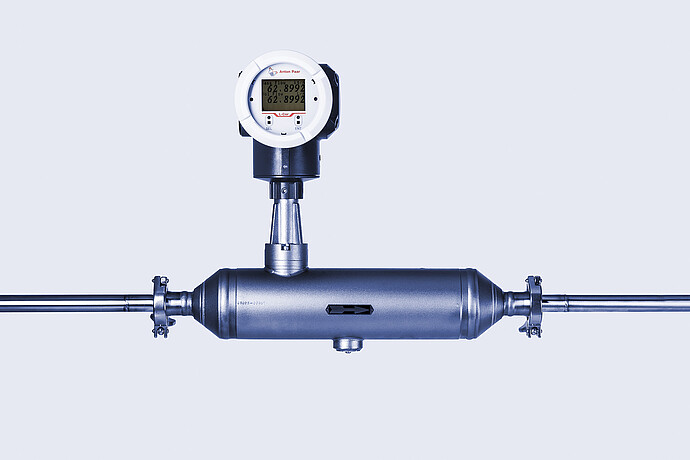

Hygienic Flow Meter:

L-Cor

- Single straight tube design provides highest hygienic conditions

- Titanium alloy for chemical resistance

- +- 0.15 % mass flow accuracy

- +- 0.002 g/mL density accuracy

Our Type S L-Cor 6000 Coriolis hygienic mass flow meters, built with titanium single straight tubes, are designed for hygienic applications. They’re your solution for highly accurate measurements of gases and shear-sensitive or viscous liquids, slurries, aggressive media, or media with a low flow velocity.

If fast and positive process fluid replacement or draining of the pipeline is what you need, then this is the mass flow meter for you.

Flow – with Anton Paar.

Key features

Hygienic flow meters that are ready for tough environments

Harness the versatility of our flow meters, designed for reliable performance even in aggressive environments. Thanks to their construction with chemically resistant titanium for the wetted parts, these meters excel in durability and corrosion resistance. You can confidently employ them in challenging settings where chemical exposure is a concern, ensuring longevity and accurate measurements. Trust our flow meters to thrive in demanding conditions while maintaining precision and stability.

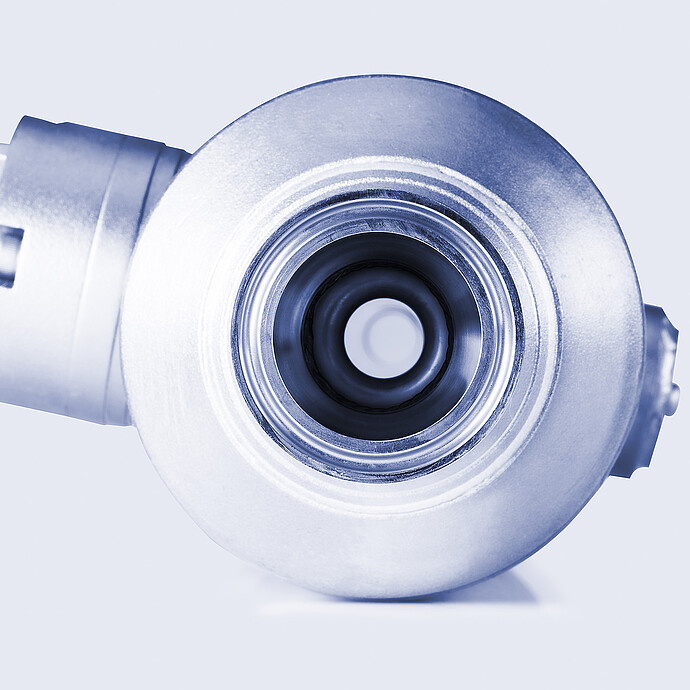

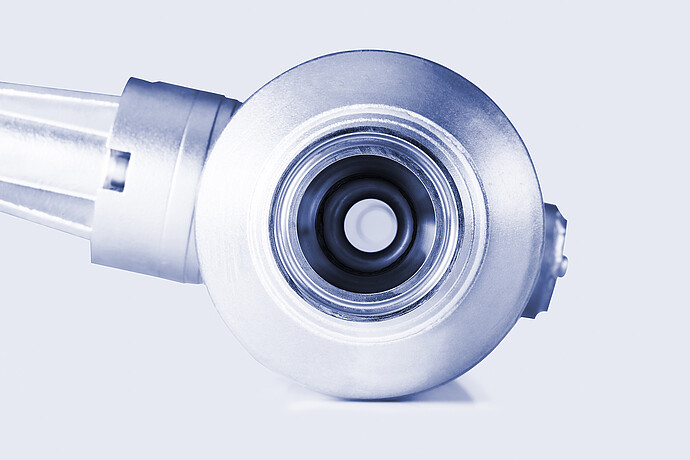

Single straight tube design means no damage to fluids

Benefit from the single straight tube design of our meters, which minimizes shear on fluids, ensuring that shear-sensitive fluids remain undamaged during the measurement process. This innovative design promotes fluid integrity and accuracy, letting you confidently handle even the most delicate substances without compromising their properties. With our meters, you can maintain the quality and consistency of your shear-sensitive fluids, making them a dependable choice for your measurement needs.

Self-draining hygienic flow meters that are easy to clean

Our sensors, featuring a straight tube design, offer the added advantage of self-draining after use, ensuring that no residual contaminants linger. This feature makes them the ideal choice for hygienic processes where cleanliness is needed. By preventing the risk of contamination, our hygienic flow meters not only uphold the integrity of your processes but also enhance safety and compliance standards. Trust in our sensors to maintain the highest levels of hygiene and performance for your critical applications.

Need hygienic versions? No problem

Explore the versatility of our EHEDG-certified sensors, specifically designed to meet the rigorous demands of hygienic process environments. With these sensors, you can confidently operate in settings where maintaining the highest standards of cleanliness is essential. Their certification ensures that your processes not only meet but exceed hygiene requirements, making them the ideal choice for critical applications that prioritize both safety and precision.

Straight tube design increases efficiency

Thanks to the straight tube design of our sensors, you can rest assured that even fluids laden with solids, such as yogurt with pieces of fruit, won't block the sensor. This design ensures unimpeded flow, preventing blockages and maintaining accurate measurements in challenging environments. It's a testament to the reliability and versatility of our sensors, making them a top choice for applications where fluid consistency varies.

A partner with broad knowledge in concentration measurement

Partner with us, and gain the advantage of collaborating with a trusted ally possessing extensive expertise in concentration measurement. Our knowledge spans a wide spectrum of applications, ensuring that you receive tailored solutions and invaluable insights to meet your specific needs. With our partnership, you tap into a wealth of experience and guidance, empowering you to excel in concentration measurement.

Technical specifications

| L-Cor 6000 | |

| Flowrate | 36 kg/h to 61 200 kg/h |

| Flow accuracy | ± 0.15% ± ZS* |

| Flow repeatability | ± 0.075% ± ½ ZS* |

| Density range | 500 kg/m3 to 1,000 kg/m3 or 700 kg/m3 to 1,300 kg/m3 or 1000 kg/m3 to 1,500 kg/m3 |

| Density accuracy | ± 2 kg/m3 |

| Nominal diameter | 1/2” to 3” |

| Ambient temperature | - 40 °C to +55 °C |

| Process temperature | - 40 °C to +130 °C |

| Process pressure absolute | According to flange specification |

| Process connection | ASME B16.5 Class 150 Tri-clamp ISO 2852 |

| Wetted parts | Titanium alloy |

| Ex-version | ATEX/IECEx CSA NEPSI |

| Communication | Bell 202/Analog Modbus/Analog Profibus PA Fieldbus |

| Transmitter mounting | Integral/ separate |

*Accuracy valid at reference conditions. ZS = Zero stability error = (Zero stability)/(Flowrate at the moment) x100%

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty