Density and Sound Velocity Meter:

DMA 6002 Sound Velocity

- Combined density and sound velocity measurement in one instrument

- Determines concentration of two- and three-component solutions

- Two industry-specific profiles: “Beverages” and “Chemicals”

- Built on 40+ years of application experience

Experience the future of lab analysis with DMA 6002 Sound Velocity – the latest evolution of the world’s most trusted density and sound velocity meter. Built on over 40 years of innovation and precision, it’s the only instrument that combines density and sound velocity in one setup, delivering fast, automatic concentration determination of two- and three-component solutions. Designed for the highest demands in QC and R&D, DMA 6002 Sound Velocity is trusted across industries for reliable results. Handling up to 30 samples per hour, it minimizes manual effort and maximizes productivity. From beverages to chemicals, it’s the smart choice for anyone ready to transform lab workflows.

Customized solutions

Key features

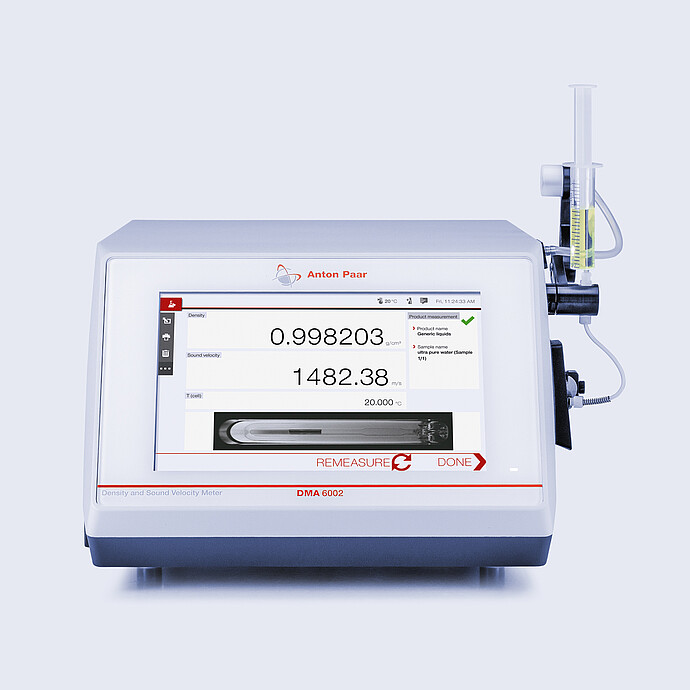

Density and sound velocity measurement combined in one instrument

DMA 6002 Sound Velocity is the only instrument that seamlessly combines density and sound velocity measurement in a single setup – delivering fast, highly precise results for the concentration determination of two- and three-component solutions.

- Density: Repeatability up to 0.000001 g/cm³

- Sound velocity: Repeatability up to 0.1 m/s

- Reproducibility: 0.000005 g/cm³ / 0.5 m/s

- Minimal sample volume of just 3.5 mL

- Up to 30 samples measured per hour

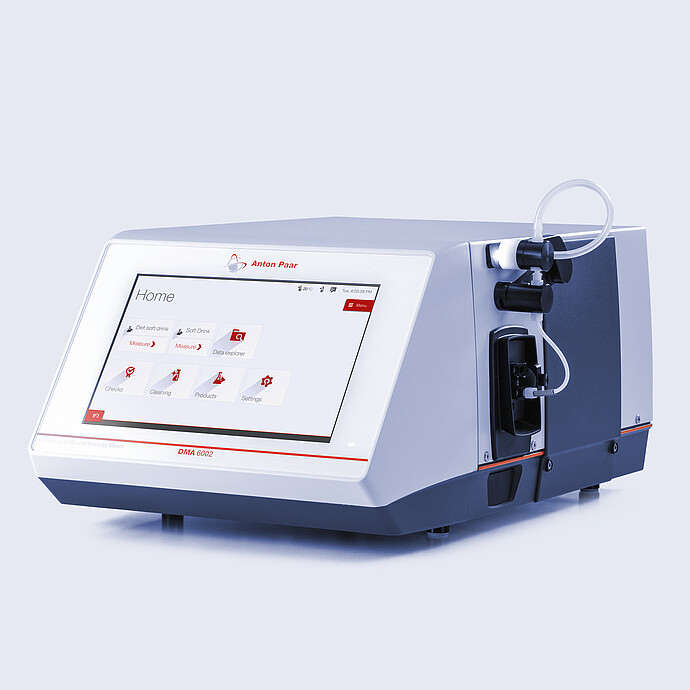

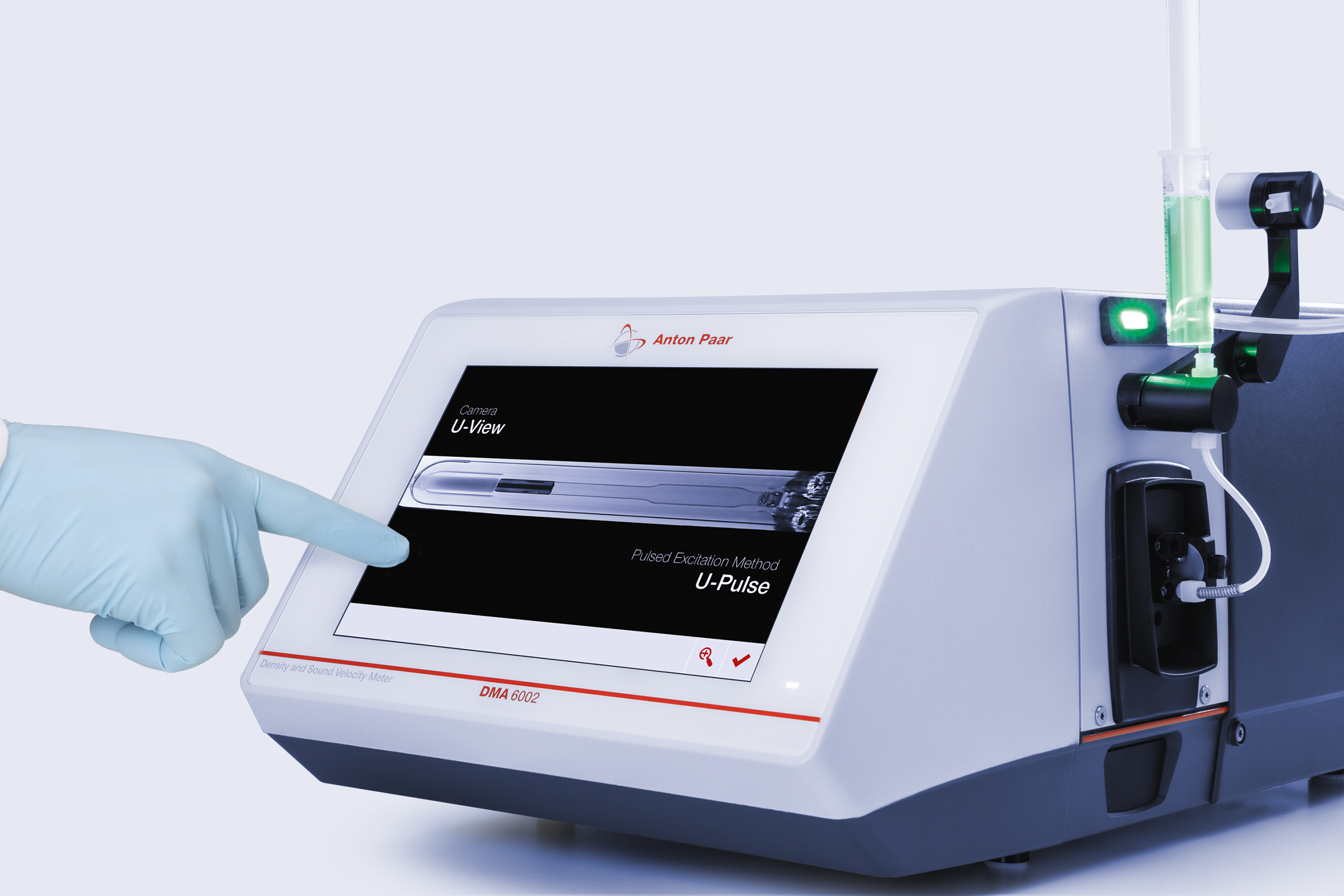

Perfect simplicity

The latest version of the world’s most trusted density and sound velocity meter makes daily operation easier than ever before. From start to finish, everything is designed for speed, clarity, and ease of use – no extensive training required.

- One-touch measurement for analysis at the push of a button

- Status light for measurement progress at a glance

- Syringe illumination for visibility during sample filling

- Guided workflows and selectable industry profiles

- Automatic bubble detection to ensure error-free results

- Smart features like U-View, U-Dry, U-Pulse, and FillingCheck

40+ years of application expertise

With more than four decades of experience built into its design, DMA 6002 Sound Velocity offers over 30 integrated methods. It is ideally suited to a wide range of industries – particularly chemical production and beverage manufacturing.

- Predefined tables for acids, bases, and inorganic salts

- Extract and sugar analysis, including sugar inversion monitoring

- Simple, reliable ternary mixture analysis

- Built-in functionality for diet soft drink analysis

- Optimized for both R&D and routine quality control

Modularity for multiparameter analysis

Achieve exceptional efficiency and analytical depth with DMA 6002 Sound Velocity at the heart of your multiparameter measurement system. More than 10 key parameters can be measured in a single cycle from one sample – faster, smarter, and under identical conditions. This modular setup enhances laboratory throughput and data integrity while seamlessly adapting to diverse application requirements.

- Combinable with modules for CO₂, O₂, pH, turbidity, and RI

- Automated handling via Xsample sample changers

- Compatible with PFD Piercing and Filling Device

- All results traceable to one sample, under one setup

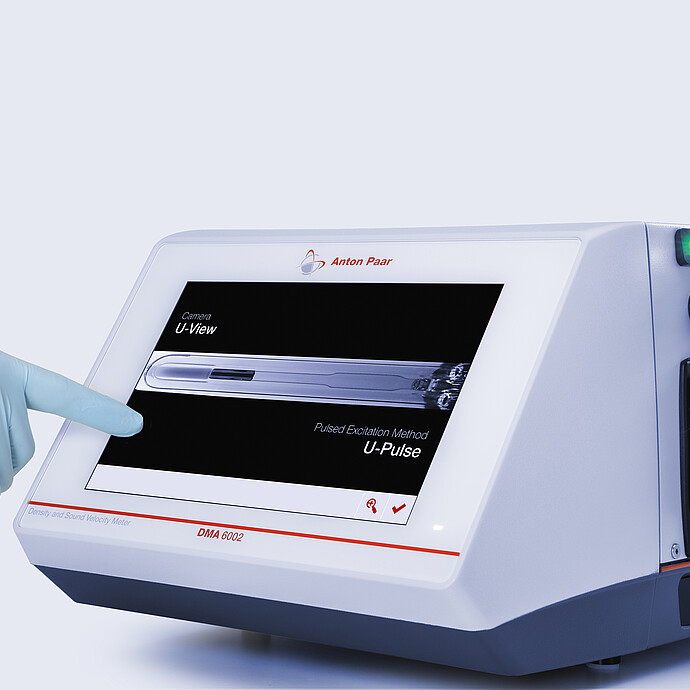

The most stable results available

DMA 6002 Sound Velocity delivers unmatched stability and precision. From microbubble detection to automated compensation of U-tube aging, every detail is engineered to simplify workflows and ensure every result is accurate, traceable, and reproducible – even under challenging sample conditions.

- FillingCheck detection of gas bubbles and filling errors

- U-View live imaging for instant validation of filled U-tube

- ThermoBalance correction of temperature effects without delay

- Viscosity correction across the entire viscosity range

- Ultra-fast measuring mode for maximum throughput

Anton Paar certified service: global support, local assistance

Anton Paar’s global network of 85+ service partners and 38+ subsidiaries ensure fast, local support – in the customer’s language. More than 350 manufacturer-certified experts are on-hand to protect each customer’s instrument investment from day one.

- Rapid on-site assistance

- Three-year warranty with every instrument

- Guaranteed spare parts availability for 10+ years

Specifications

| DMA 6002 Sound Velocity | |

|---|---|

| Patents | AT 516420 B1 |

| Measuring range | |

| Density | 0 g/cm³ to 3 g/cm³ |

| Sound Velocity | 1,000 m/s to 2,000 m/s |

| Temperature | 0 °C to 100 °C (32 °F to 212 °F) |

| Pressure | 0 bar to 8 bar (0 psi to 116 psi) |

| Accuracy* | |

| Density | 0.000005 g/cm³ |

| Temperature | 0.01 °C (0.02 °F) |

| Repeatability s.d.** | |

| Density | 0.000001 g/cm³ |

| Sound Velocity | 0.1 m/s |

| Temperature | 0.001 °C (0.002 °F) |

| Reproducibility s.d.** | |

| Density | 0.000005 g/cm³ |

| Sound Velocity | 0.5 m/s |

| Digital resolution | |

| Density | 0.000001 g/cm³ |

| Sound Velocity | 0.01 m/s |

| Features | |

| Power features | U-Dry, U-View, U-Pulse, FillingCheck, Status Light, Syringe Illumination, ThermoBalance, Full-range viscosity correction |

| Special functions | Temperature scan, built-in ambient pressure sensor, condition monitoring |

| Filling options | Automatic sample changers |

| Modularity | Alcohol, pH, color, turbidity, viscosity, refractive index, optical rotation, CO₂, O₂ |

| Upgrades and calibrations | Printers, ISO calibration, AP Connect lab execution software |

| Integrated tables and functions | Density, specific gravity (SG), alcohol tables, sugar/extract tables, various acid/base tables, API functions |

| Technical data | |

| Ambient temperature | 15 °C to 35 °C (59 °F to 95 °F) |

| Typical measuring time/sample | 0.5–6 min |

| Minimum sample volume | 3.5 mL |

| Wetted materials | Borosilicate glass, PTFE, ETFE, Stainless steel DIN 1.4539 / UNS N08904, HTL 5 CR (solder, sound velocity cell) |

| Dimensions (L x W x H) | 526 mm x 347 mm x 230 mm (20.7 in x 13.7 in x 9 in) |

| Weight | 22.62 kg (49.87 lbs) |

| Power supply | AC 100 to 240 V, 50/60 Hz, fluctuation ± 10 %, 190 VA |

| Display | 10.1" TFT WXGA (1280 x 800 px); PCAP touchscreen |

| Controls | Touchscreen, optional keyboard, mouse, and barcode reader |

| Communication interfaces | 4 x USB, Ethernet, CAN, RS232 |

| Internal storage | 10,000 measuring values including camera images |

* According to ISO 5725

** Under ideal conditions and for low viscosities

Standards

ISO

ASTM

JIS

OIML

OIV

AOAC

ASBC

European Union

HM Revenue & Customs

EBC

IP

GB

HG

JJF

QB

SH

ABNT

RANP

TTB

DIN

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Temperature-adaption: Determining the Thermal Expansion Coefficient Application Reports

-

Brochure | Good density measurement Brochures

Similar products

Complementary products

If you do not find the item you require, please contact your Anton Paar sales representative.

ISO 17034-Certified Reference Material:

Density Standards

- Market-leading uncertainty of 0.015 kg/m³ (ISO 17034)

- Application-specific density standards, available via webshop

- Online certificate with lifetime reference values guarantee

- Conformity with ISO requirements ISO 17025 and even ISO 17034

- Safety glass ampoule for zero contamination

Sample Changer:

Xsample 520

- The multi-sample changer that provides first-class filling at a snap

- Handles up to 96 samples in one magazine

- Ideal for beer, wine, soft drinks, syrups, and other aqueous samples which can be replaced without intermediate cleaning

- Multiple fillings from the same vial if required

Sample Changer:

Xsample 320

- The single sample changer for easy operation

- Multiple fillings from the same vial if required

- Highly resistant wetted parts for handling of aggressive samples

- Quick replacement of the sample without intermediate cleaning

Lab Execution System:

AP Connect Start

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

Lab Execution System:

AP Connect Standard subscription license

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma subscription license

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Standard one-time license

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution System:

AP Connect Pharma one-time license

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips