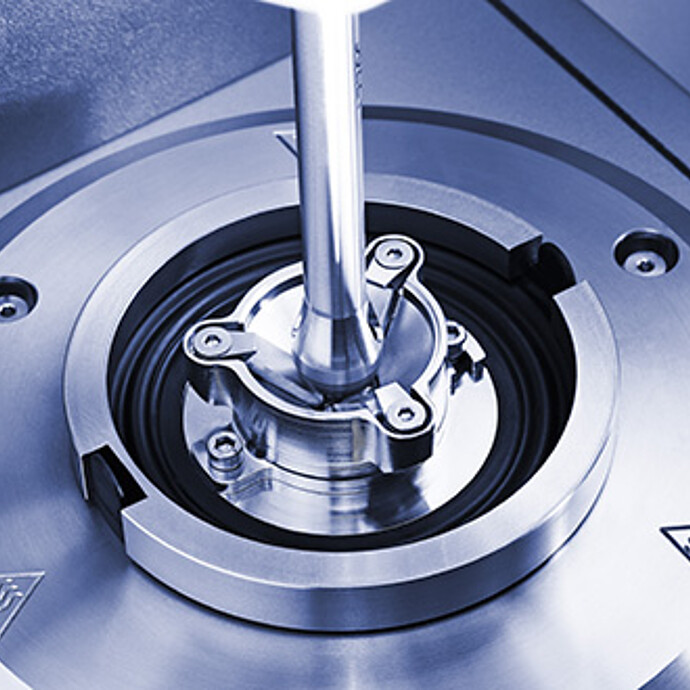

MCR Tribology Cell:

T-PTD 200

- Based on the ball-on-three-plates measuring principle

- Excellent temperature control from -40 °C to +200 °C

- Sliding speed control of up to 3.3 m/s

- Rolling bearing attachment optional

The ball-on-three-plates setup is a well-established method for measuring both lubricated as well as dry tribological systems. Different measuring geometries (plates, cylinders) are available for adaptation to specific sample needs. The heart of this setup is the T‑PTD 200 tribology cell which ensures precise alignment and therefore a homogeneous distribution of normal forces on the measured samples. To investigate lubricant performance in a bearing or to characterize the bearing itself, the T‑PTD 200 tribology cell can be equipped with a rolling bearing attachment. With this setup, different bearing types can be measured under axial loads.

Key features

Technical features

- Options

- Ball-on-three-plates

- Rolling bearing test

- The Peltier heating system: excellent temperature control from -40 °C up to 200 °C for all options

- Maximum torque: 300 mNm

- Sliding speed control between 10‑8 and 3.3 m/s

Software

- Flexible test programming in rotation and oscillation

- Pre-defined workbooks for Stribeck curves and static friction tests

Specifications

| T-PTD 200 | Ball-on-three-plates | Rolling bearing test |

|---|---|---|

| Tribological normal force FN,Tribo | 1 N to 24 N | 1 N to 50 N |

| Sliding speed vs | 10-8 m/s to 1.4 m/s (3.3 m/s-1) | - |

| Speed U | 10-6 rpm to 3000 rpm | |

| Temperature T | -40 °C to 200 °C | |

| Deflection angle φ | 1 µrad to ∞ µrad | |

| Contact types | Point | Component |

| Specimen sizes | 12.7 mm setup Ball: 12.7 mm Plates (LxWxH): 15 mm x 6 mm x 3 mm Pins (diameter, length): 6 mm, 6 mm 30 mm setup Ball: 30 mm Plates (LxWxH): 10 mm x 10 mm x 3 mm | Min. inner diameter: 3 mm Max. inner diameter : 25 mm Min. outer diameter: 10 mm Max. outer diameter: 42 mm |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Tribological Testing of Bituminous Mastics Application Reports

-

Instruments - MCRxx2 Evolution series Brochures