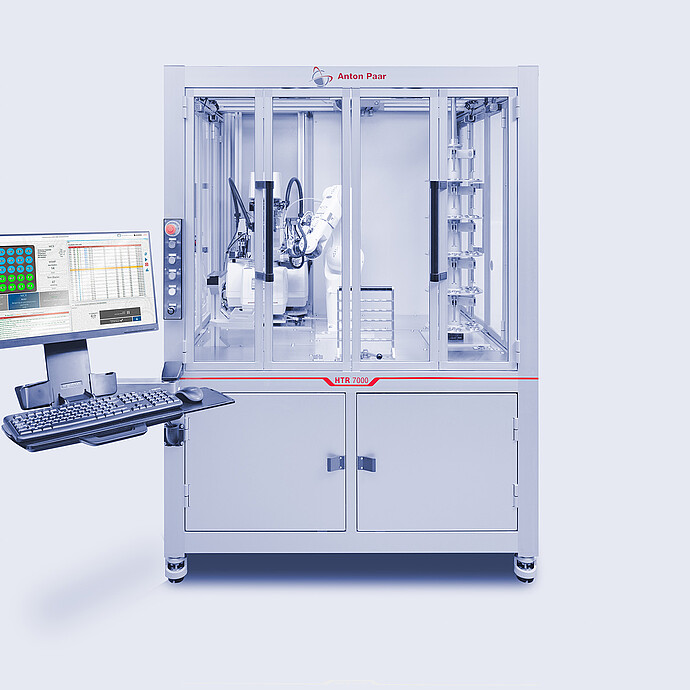

Rheometer Automation for High Sample Throughput and Complex Sample Handling:

HTR

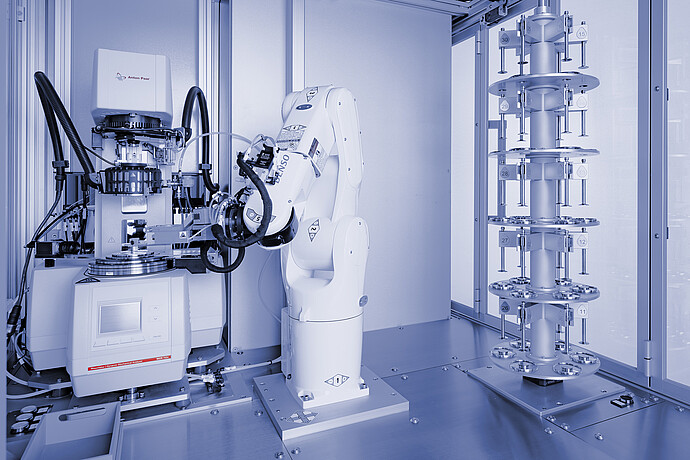

The HTR automation series offers an optimized analysis workflow for rheological investigations based on Anton Paar’s MCR 702 rheometer. The extensive set of features and the built-in flexibility make it the ideal choice for sophisticated and high-throughput R&D or QC work.

Key features

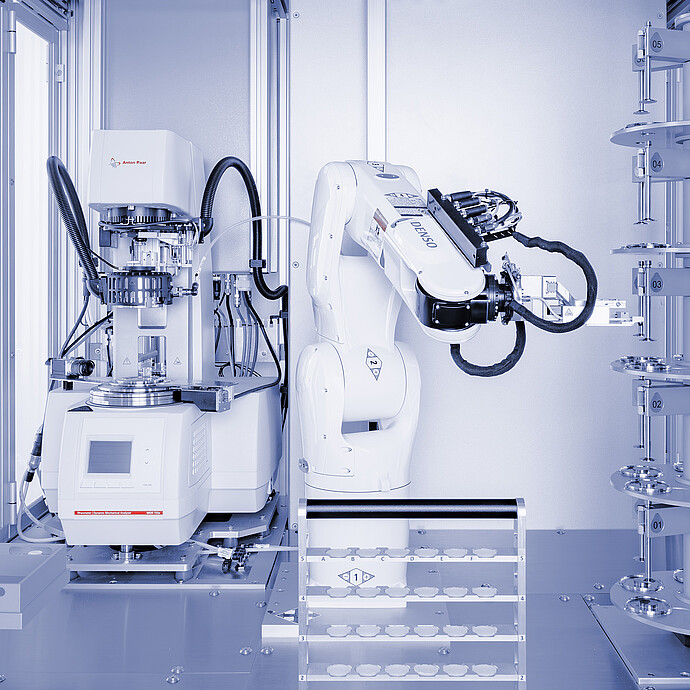

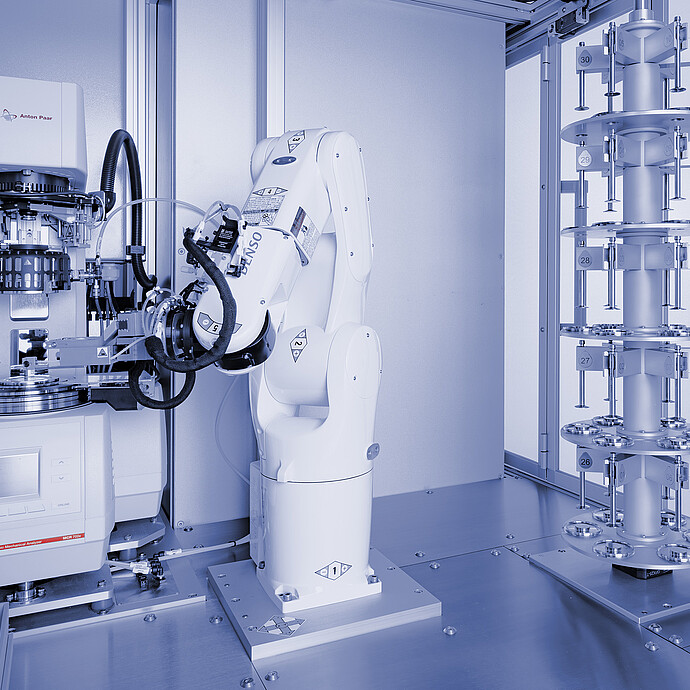

Maximized operation flexibility

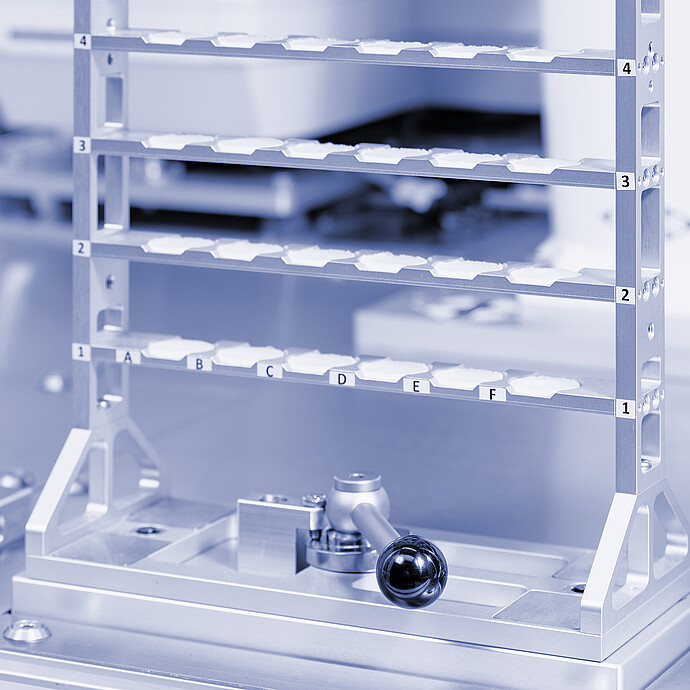

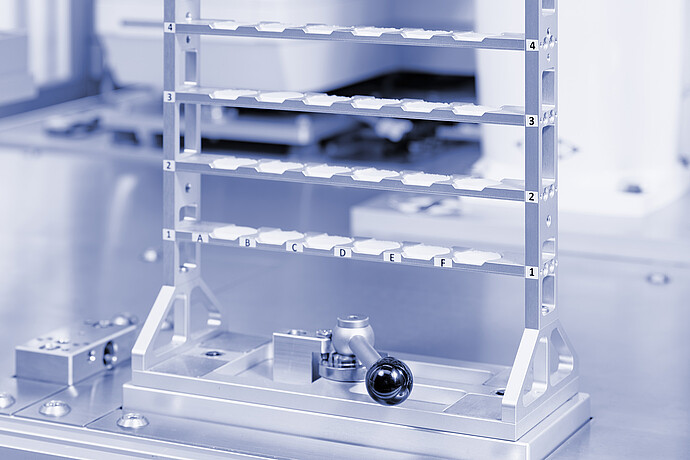

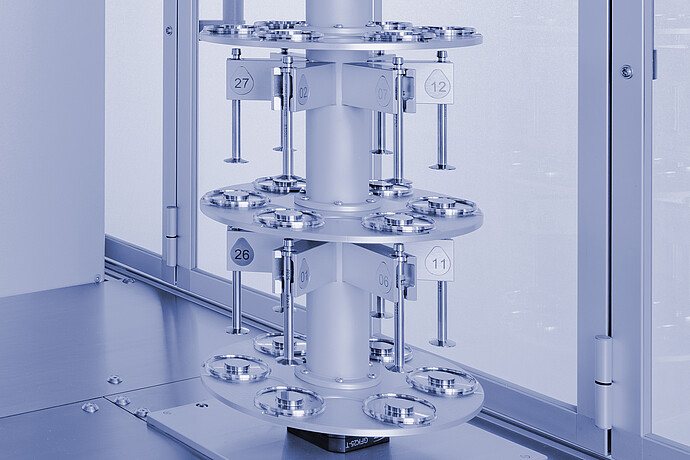

HTR can be equipped with up to 96 measuring geometry units (e.g. for polymer melts) and offers three different rheological geometries (CC, CP, PP) The standard rack configuration holds 96 samples. Different types of racks for pipettes, syringes, and trim blades and temperature-controlled sample storage (down to 4 °C) are available.

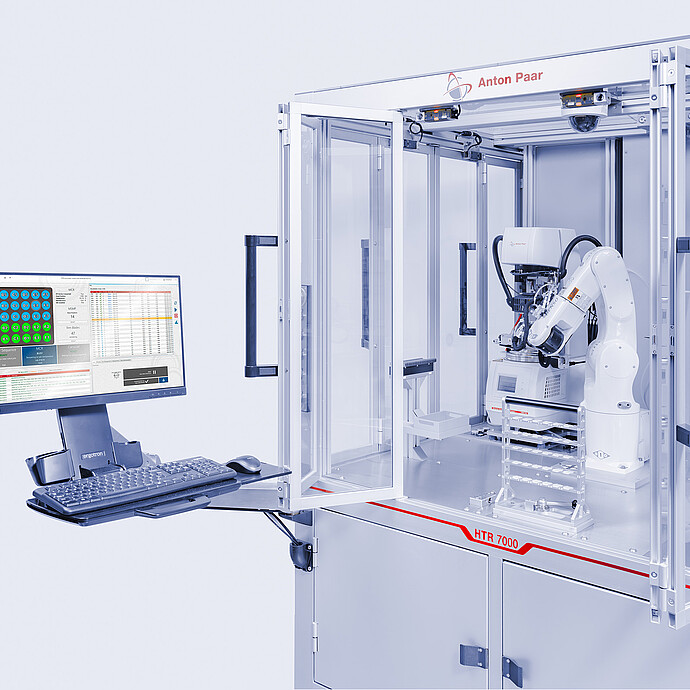

Perfectly safe and accurate workflow

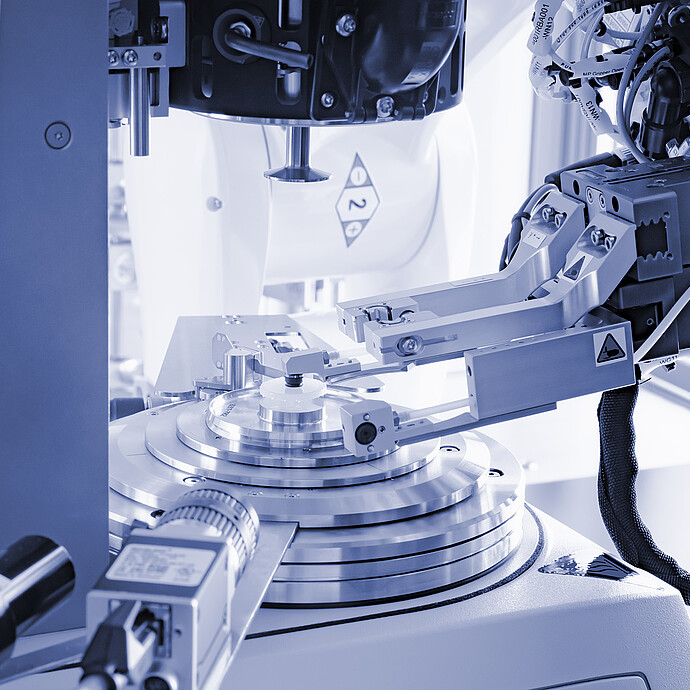

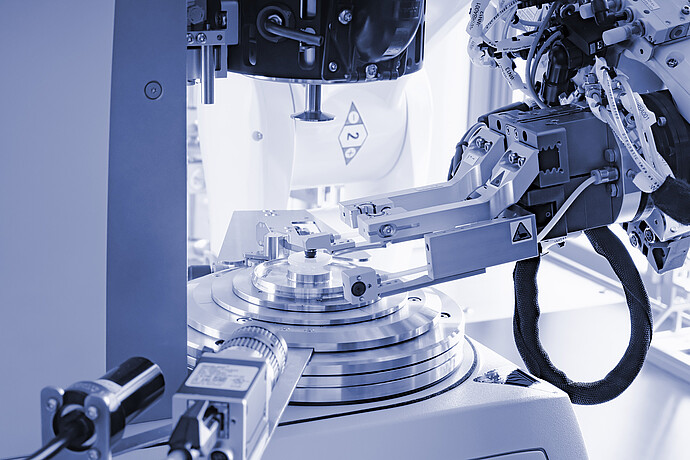

HTR achieves lab accuracy due to the mechanical decoupling of rheometer and automation unit and is set up for maximum efficiency:

- Sample management by using job lists

- LIMS integration (file transfer, database, Ethernet)

- Priority samples can be introduced at any time

- Four-stage programmable cleaning station (rinse, brush, clean, dry)

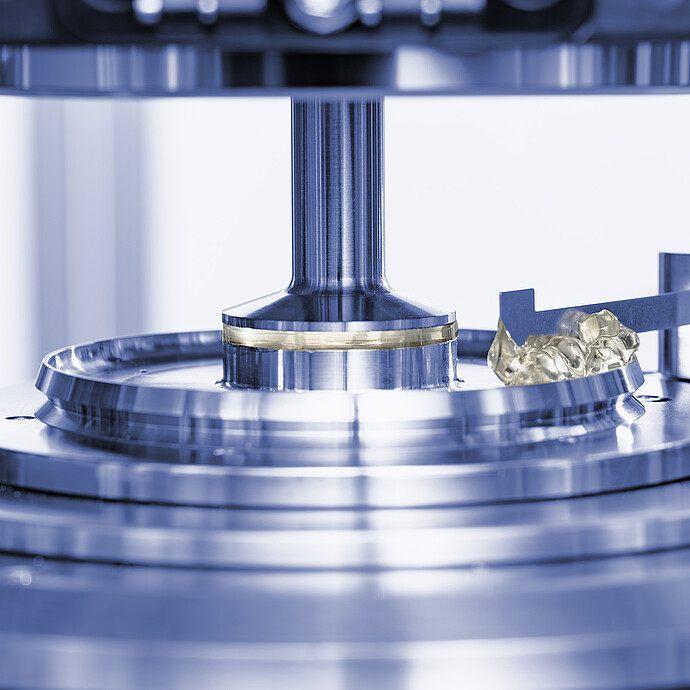

- Integrated trim tool removes excessive sample material to avoid wrong measurement results

- Visual verification of trim result

Masters all kinds of rheological samples

HTR offers different systems for:

- Dispensable samples

System for liquid samples with up to 1000 mPa.s which are suited for exact dispensing - Low-viscosity samples

System for concentric cylinder measurements for low-viscosity samples - Paste-like samples

System for paste-like or gel-like samples which are not suited for exact dispensing - Polymer melts

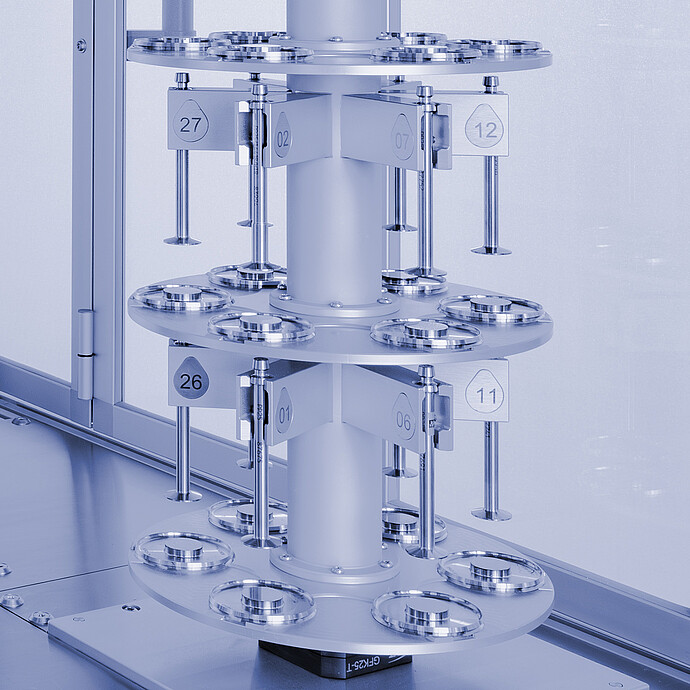

System for measuring polymer melts from disk-shaped samples

Additional modules for growing automation needs

The following additional modules can be selected:

- Gravimetric and volumetric dosing and weighing

- pH measurement

- Capping/decapping of sample cups or vials

- Various gripper tools for samples, measurement geometries, and disposables

- Precise dosing of sample liquids via pipettes and/or syringes

- Automatic cutting of pipette opening to reduce shear stress

- Shaker module for reproducible shaking

- Bar code reader for sample identification, process control, and logging

- Ventilation for volatile and solvent-based samples

Where precision meets performance

Anton Paar’s global sales and service network is close to you from the project definition to execution and commissioning, and offers comprehensive training, support, and individual maintenance and service.

Automated solutions from Anton Paar represent trustworthy measuring technology and automation from a single source.

Technical specifications

| Dimensions (W x D x H) | 1800 mm x 1200 mm x 2000 mm | |

| Weight (net) | 900 kg | |

| Mains supply | 400 V, 16 A, 50/60 Hz | |

| Media interfaces | Compressed air, cleaning solvents | |

| Waste disposal | Drain for liquids | |

| Communication interface | Ethernet | |

| Rheometer specifications | ||

| MCR 702 MultiDrive | ||

| Max. torque | 230 mNm | |

| Min. torque (rotation) | 1 nNm | |

| Min. torque (oscillation) | 0.05 nNm | |

| Max. angular velocity | 314 rad/s | |

| Max. angular frequency | 628 rad/s | |

| Normal force range | 0.005 N to 50 N | |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Brochure HTR 3000 Brochures