Anton Paar Density Meters: New Glass U-Tube Production and Improved Calibration

2025-03-31 | Corporate

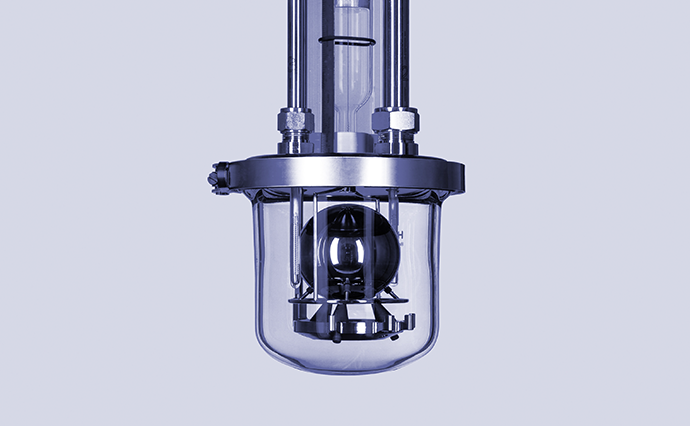

Increased production of the most precise glass U-tubes

The heart of Anton Paar’s DMA density meters is the measuring sensor made of borosilicate glass. This material is characterized by high chemical resistance, mechanical stability and low thermal expansion. These glass components are manufactured under strict quality control in the company's new in-house glass production facility next to the Technology Center at Anton Paar’s headquarters in Graz. This means that every production step can be monitored and optimized, resulting in even lower production tolerances. The investment in the new glass production facility enables a significant increase in production figures for the most precise glass oscillating U-tubes.

Pulsed Excitation Method (PEM) and its advantages

A key feature of the DMA series is the patented “Pulsed Excitation Method” (PEM). Here, a U-tube made of glass is set into natural oscillation, allowing the density of the sample to be determined with high precision. This method reduces measurement deviations and increases the long-term stability of the system. The improvement in glass bending oscillator production helps to further increase the sensitivity of this technology and thus enable even more precise measurements.

Hydrostatic balance and ISO certifications

Alongside the optimization of glass production, Anton Paar has also invested in improving its hydrostatic balance. This is crucial for the highly accurate determination of reference materials and forms the basis for traceable calibration of the measuring instruments. ISO 17034 certification ensures that the calibration standards meet the highest requirements in terms of reliability and stability, while ISO 17025 covers all calibration activities within the scope of accreditation and their traceability. These certifications guarantee the highest quality standards and ensure that the measuring instruments can be used as reference systems worldwide.

Impact on research and industry

Advancements in glass manufacturing and calibration technology have a direct impact across many applications. All industries benefit from the improved measurement accuracy, enabling them to take quality control and optimization to a new level. Another advantage: the increased precision also allows for faster measurement processes – saving both time and costs. In regulated environments, where compliance with laws and standards is essential, these innovations provide a clear competitive edge.

By combining innovative sensor technology, optimized production, and strict quality control, Anton Paar strengthens its position as a leader in digital density measurement. Investments in new production methods and calibration procedures underline the company’s long-term commitment to precision and reliability.

The DMA: Always superior for you.