Density Meter:

DMA 4100 M

- Measure density and concentration at 4-digit accuracy

- Only 30 seconds per measurement for high-throughput quality control

- The first choice for petroleum sample measurement according to ASTM standards

DMA 4100 M delivers the 4-digit density values you need and is not affected by your working environment and workforce. It applies the patented Pulsed Excitation Method to deliver the most stable density results based on comprehensive knowledge of the oscillation characteristics. This method results in viscosity correction which is twice as effective as anything else available on the market. The integrated camera allows you to check the filling procedures of your operators at any time and also at the end of the working day. The patented condition monitoring ensures that frequently changing users with differing filling approaches, humidity, temperature fluctuations, air pressure, and instrument condition all have no effect on the operation and results – built-in intelligence for your convenience.

Key features

A revolutionary density measuring principle for quick and easy quality control

The unique design of the measuring cell, a novel way of evaluating the oscillation characteristics, and many other innovative features lead to the following:

Unaffected by harsh working conditions

- Stable results under varying conditions, such as humidity, temperature and air pressure

- Housing withstands shocks, dirt, and spillages

- Frequently changing users and filling styles do not influence the measurement results

Supervise all filling procedures and be alerted if there is an error

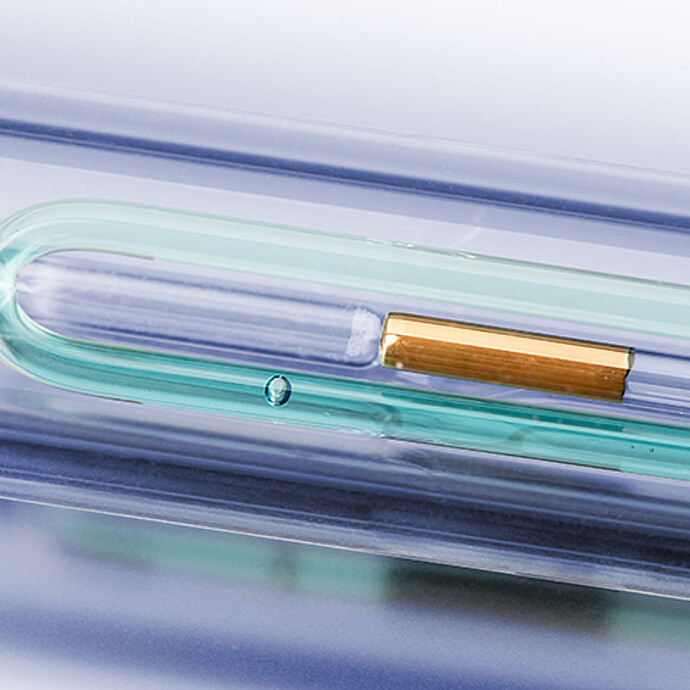

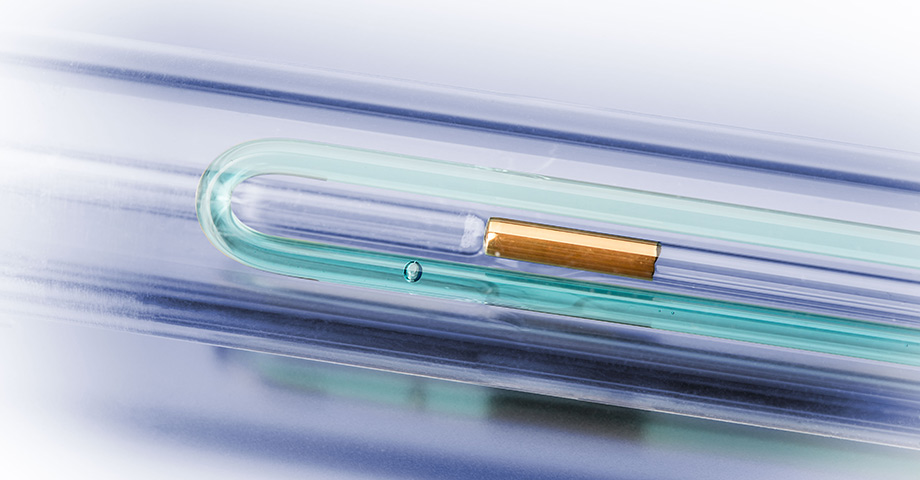

- The U-View™ camera feature displays and stores live images of the oscillating U-tube sensor and the entire filled-in sample

- Relevant images with the sample fully and clearly visible are stored in the data memory

- Later review of these images guarantees completely transparent measurement processes

Automatic bubble detection

- Monitor your sample handling with the FillingCheck™ that detects filling errors, gas bubbles and particles in the sample

- FillingCheck™ generates and records filling warnings

- U-View™ and FillingCheck™ supervise the entire measurement sequence and allow later verification of the results, which is particularly useful when using automatic sampling systems

Touchscreen for premium user experience

- The only density meter with PCAP touchscreen technology for unmatched sensitivity and robustness at the same time

- Easy operation, even when wearing gloves

- Large screen, readable from a distance due to adaptable font sizes

Specifications

| DMA 4100 M | DMA 4500 M | DMA 5000 M | |

|---|---|---|---|

| Patents granted |

|

|

|

| Patents pending |

|

|

|

| Measuring range |

|

|

|

| Repeatability s.d.(1) |

|

|

|

| Reproducibility s.d.(1) |

|

|

|

| Accuracy(2) |

|

|

|

| Digital Resolution |

|

|

|

| Integrated tables and functions |

|

|

|

| Minimum sample amount |

|

|

|

| Measuring time per sample(3) |

|

|

|

| Dimensions (L x W x H) |

|

|

|

| Data memory |

|

|

|

| Power supply |

|

|

|

| Weight |

|

|

|

| Interfaces |

|

|

|

| Display |

|

|

|

| Wetted parts |

|

|

|

| Industries |

|

|

|

(1) according to ISO 5725

(2) under ideal conditions and for low densities/viscosities

(3) After temperature equilibration

Standards

ISO

ASTM

JIS

OIML

OIV

AOAC

ASBC

European Union

HM Revenue & Customs

European Pharmacopoeia (Ph. Eur.)

US Pharmacopoeia (USP)

EBC

IP

GB

HG

JJF

QB

SH

ABNT

RANP

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty