XRD analyzers are powerful instruments used in material science across academia and industry for non-destructive material characterization. By utilizing the principles of X-ray diffraction, they reveal the atomic structure of crystalline materials, delivering information related to crystal structures, lattice parameters, crystallinity, and occurring phases. XRD analyzers are indispensable in advancing research, ensuring product quality, and driving innovation across industries – from pharmaceuticals to electronics, metallurgy, and mining.

Core capabilities of XRD analyzers

XRD analyzers work by directing X-rays at a sample, which are then diffracted by the atoms in the crystal structure. The diffracted X-rays create a unique pattern that provides information about the material's atomic arrangement. This technique is based on Bragg’s Law, which relates the diffraction angle to the lattice spacings of the crystallographic planes in the crystal. XRD is highly effective for phase identification, crystallinity studies, and structural analysis.

In material characterization, XRD analyzers provide valuable insights into the composition, strain, stress, and texture of materials. They are capable of distinguishing between polymorphs, detecting impurities, and offering detailed structural information crucial for product development and research. XRD measurements are widely used across academia and industry, including pharmaceuticals, metals, ceramics, and nanomaterials, for both qualitative and quantitative analysis, making them a fundamental tool in modern material science.

Key features of XRD analyzers

XRD analyzers come with a range of features designed to enhance their functionality and ensure precise, reliable results in material characterization.

Data collection

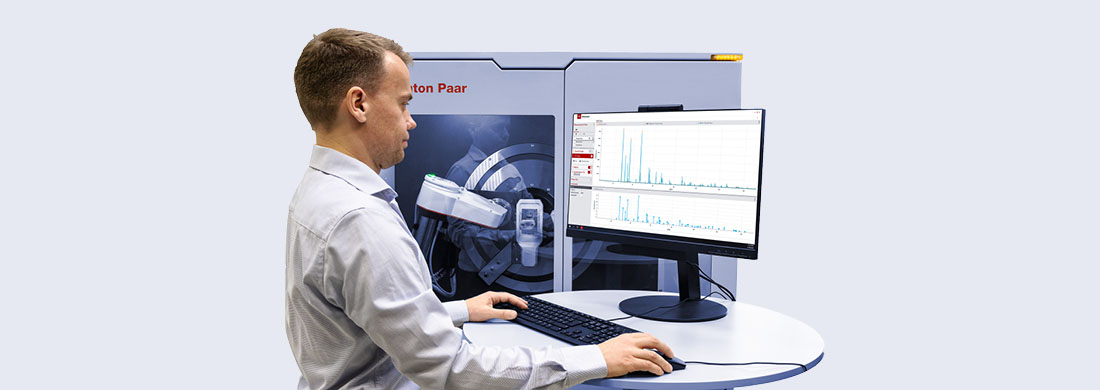

XRD analyzers provide high-resolution diffraction patterns that allow for the detailed investigation of material structures. This ensures that even minor changes in crystal structure or phase composition can be detected and quantified accurately.

Non-destructive analysis

One of the key advantages of XRD analyzers is their ability to investigate materials without prior sample preparation or damage to the sample. This non-destructive approach is ideal for high-value samples or those that require preservation for further testing.

Automation

Modern XRD analyzers are highly automated systems that enable the changing of measurement parameters with a click of the mouse, streamlining the analysis process and reducing human error. This feature is especially valuable in regulated environments, where traceability is critical.

Versatility

XRD analyzers are designed to allow users to easily collect, view, and analyze data. Their modular approach allows optimized solutions for any sample, from powders to thin films and bulk materials.

Advanced technologies in XRD analysis

XRD analyzers have advanced significantly over the years, incorporating cutting-edge technologies to improve accuracy and efficiency in material characterization.

Optimized beam paths

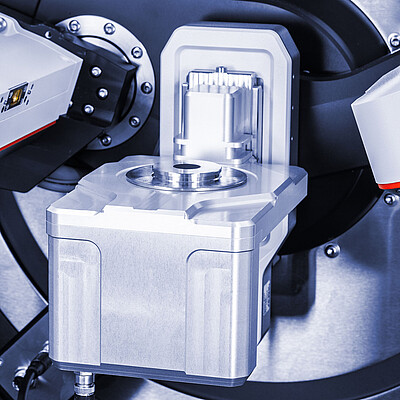

Modern XRD analyzers are equipped with high quality components along the entire beam path, from the X-ray source to the sample stage and detector. Components can be exchanged automatically to ensure every sample is measured with the ideal configuration. An evacuated beam path allows larger goniometer radii leading to improved resolution, without compromising on data quality or measurement speed.

Rietveld refinement

Rietveld refinement enables precise fitting of diffraction patterns to obtain detailed structural information. This method is crucial for complex crystal structures where traditional analysis techniques may fall short.

Goniometers

Goniometers are the heart of every XRD analyzer, enabling precise positioning of components and the collection of high-precision diffraction data. The advanced technology provides the necessary reliability and stability required, while reducing maintenance and down-time.

In situ measurement capabilities

In situ XRD technology allows researchers to analyze materials under various environmental conditions, such as varying temperature or atmospheres. This is crucial for studying phase transitions and real-time structural changes.

Automation

Automation in XRD analyzers significantly enhances usability. Automated routines for aligning both the analyzer and the sample ensure consistently high-quality data, independent of the user’s knowhow. Switching analyzer components without the need for manual intervention reduces training time and ensures a well-maintained instrument. Combined with component recognition, measurements are easily traceable and repeatable.

Applications of XRD Instruments

Material science

XRD analyzers are widely used in material science to investigate the crystalline structure of metals, polymers, ceramics, and other materials. They provide critical information on phase composition, crystal structure, and lattice parameters, which are essential for both developing new materials and improving existing ones.

Pharmaceuticals

In the pharmaceutical industry, XRD analyzers are used to analyze active pharmaceutical ingredients (APIs) and excipients. They help ensure drug stability, efficacy, and compliance by identifying polymorphic forms and detecting impurities in pharmaceutical compounds.

Nanotechnology

XRD provides insights into crystallinity, crystal structure, and phase composition of nanomaterials to optimize the performance of nanoparticles in applications such as coatings, catalysts, and electronics.

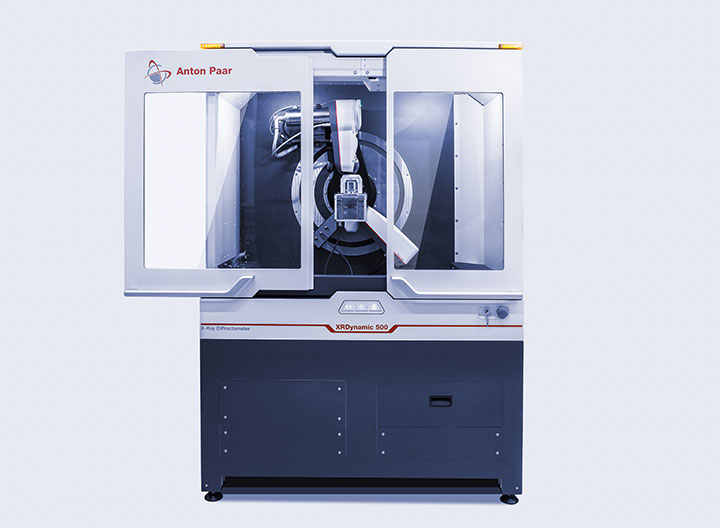

XRDynamic 500: Versatile and powerful XRD analysis

XRDynamic 500 is a state-of-the-art XRD analyzer designed to deliver high-precision results for a wide range of applications. With its modular design, XRDynamic 500 offers unparalleled flexibility, making it suitable for both routine analysis and advanced research. Equipped with advanced features like high-speed detectors, multi-axis goniometers, and in situ measurement capabilities, it ensures fast and accurate analysis of crystalline structures. Its automation and user-friendly interface make it an essential tool for any modern lab.

Contact us today to learn how our XRD analyzers can transform your material analysis!