In situ X-ray diffraction (XRD) is revolutionizing the way scientists and engineers study materials. The method enables researchers to observe structural changes as they happen under various environmental conditions like temperature, pressure, and gas flow. This real-time monitoring allows for deeper insights into how materials behave and transform during reactions, making it a crucial tool in material science, energy research, catalysis, and other advanced fields. Whether studying phase transitions, chemical reactions, or battery cycling, in situ XRD delivers precise and actionable data to push the boundaries of innovation.

Principles of in situ XRD

In situ XRD works by continuously capturing X-ray diffraction patterns while subjecting the sample to changing environmental conditions, such as heating, cooling, or applied pressure. This dynamic setup involves specialized equipment like high-temperature chambers, pressure cells, or reaction chambers that allow researchers to observe material behavior in real-time. By synchronizing X-ray diffraction with environmental changes, scientists can track structural changes as they occur.

Distinguishing features

What sets in situ XRD apart from traditional XRD techniques is its ability to monitor changes in real-time This makes it ideal for studying materials that undergo changes during reactions or phase transitions, such as metals, catalysts, or battery materials. The ability to collect data as changes happen offers a more comprehensive understanding of material behavior, leading to breakthroughs in various fields.

In situ XRD for dynamic studies

In situ XRD enables scientists to simulate real-world conditions – by heating a material to observe how it reacts at high temperatures or applying pressure to study phase transitions, for example. The technique is especially valuable in fields like catalysis, where understanding material behavior under operating conditions is crucial for developing more efficient catalysts.

Equipment required for in situ XRD

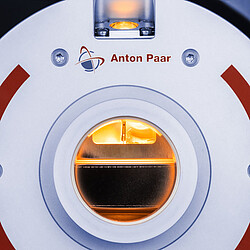

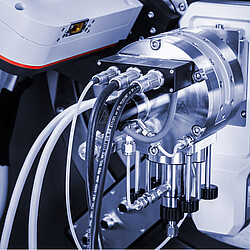

To perform in situ XRD, researchers need specialized equipment tailored to the environmental conditions being tested. Common setups include high-temperature furnaces, gas flow systems for studying reactions, and pressure cells for high-pressure experiments. These systems are integrated with X-ray diffractometers to continuously collect diffraction data while the environmental parameters change, providing real-time insights into how materials respond to different stimuli.

Technical aspects of in situ XRD

In situ XRD is a sophisticated technique that requires careful planning and specialized equipment to achieve accurate results. From experimental setups to data interpretation, understanding the technical details is essential to harnessing the full potential of this dynamic method.

Experimental setups

In situ XRD experiments are often conducted under controlled environments using high-temperature furnaces, pressurized chambers, or gas flow systems. These setups simulate real-world operating conditions, allowing scientists to study material transformations as they occur. For example, a gas flow system can be used to observe how a catalyst behaves during a reaction, while a high-temperature furnace can monitor phase transitions in metals or ceramics. Each setup is designed to provide a stable environment that aligns with the material's working conditions, ensuring accurate and meaningful data collection.

Data interpretation and challenges

Interpreting data from in situ XRD experiments can be complex due to the continuous changes occurring in the material. Researchers must carefully analyze diffraction patterns over time to identify structural transformations, phase transitions, or chemical reactions. One of the main challenges is maintaining stable experimental conditions, as fluctuations in temperature, pressure, or gas flow can affect the quality of the data. However, advanced software tools and real-time monitoring systems can help overcome these challenges, ensuring precise data interpretation and accurate results.

Applications of In Situ XRD

Material science and engineering

In situ XRD has become indispensable in material science and engineering. By providing insights into phase transformations and reaction mechanisms, researchers can gain a deeper understanding of materials at the atomic level. Whether studying the thermal stability of ceramics or the stress-induced phase changes in metals, in situ XRD allows scientists to observe these processes as they happen. This level of detail is crucial for developing new materials with tailored properties for applications such as aerospace, automotive, and advanced manufacturing.

Catalysis research

Catalysis research benefits greatly from in situ XRD, which allows scientists to study catalysts under actual operating conditions. By observing structural changes during catalytic reactions, researchers can identify how materials respond to different reactants, temperatures, and pressures. This insight helps optimize catalyst design for increased efficiency, selectivity, and stability. In situ XRD also plays a key role in understanding catalyst deactivation mechanisms, enabling the development of longer-lasting catalysts for industrial applications.

Battery and energy storage research

In situ XRD is an essential tool in battery and energy storage research, especially for monitoring structural changes in electrode materials during charge and discharge cycles. By capturing real-time data, researchers can track how materials expand, contract, or degrade with each cycle. This information helps improve the performance and longevity of batteries used in electric vehicles, renewable energy storage, and consumer electronics. In situ XRD assists to identify failure points in battery materials, leading to the development of more robust and efficient energy storage solutions.

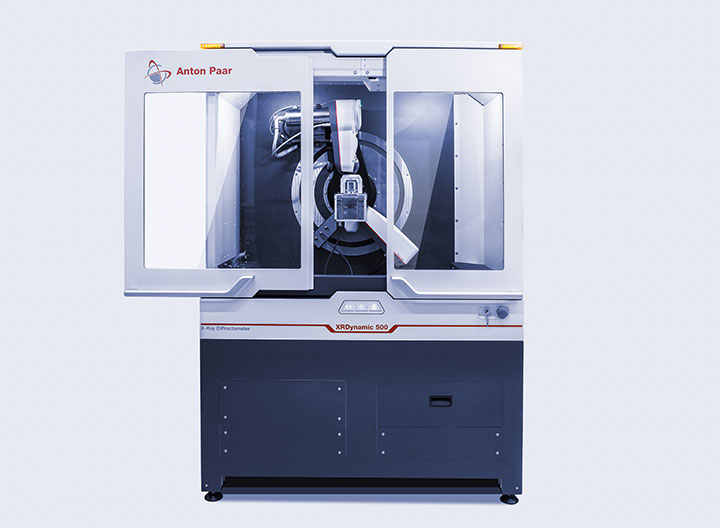

XRDynamic 500: Advanced in situ XRD solutions for comprehensive material analysis

XRDynamic 500 from Anton Paar is designed to meet the unique demands of in situ XRD experiments. In combination with Anton Paar’s non-ambient attachments, XRDynamic 500 offers unmatched flexibility for real-time material analysis. Its high-resolution detectors ensure precise data collection, while advanced software provides seamless control over experimental parameters. Whether you're studying phase transitions, catalytic reactions, or battery cycling, XRDynamic 500 delivers accurate, real-time data that drives scientific discovery and industrial innovation.

Unlock the power of real-time material analysis with in situ XRD – contact us to learn more about XRDynamic 500!