Real-Time Reactive Extrusion Monitoring

Anton Paar’s Brabender extruders are proven tools for developing and testing polymers on a lab or pilot scale. They make it possible to explore new materials, recipes, and processes under realistic conditions. By combining them with the Anton Paar Cora 5001 Raman spectrometer, you add the missing piece: real-time chemical and structural insights directly from the melt. This complementary setup supports process optimization in reactive extrusion, helping you reduce trial-and-error cycles and benefit from lower development costs, faster scale-up, and consistent product performance.

Secure blend ratios and dispersion quality

Extruders empower you to test and refine polymer blends under practical conditions. Raman spectroscopy adds immediate confirmation of blend ratios and filler dispersion, enabling corrective action during the run. Together, they reduce rejects, save material, and accelerate optimization.

Optimize reactive extrusion with confidence

Extruders provide the controlled environment needed for reactive extrusion processes. Raman spectroscopy monitors functional-group changes in real time, so you can balance conversion and degradation precisely. This synergy lowers development costs, speeds up scale-up, and strengthens IP protection with solid data.

Control crystallinity as it forms

Extrusion defines the processing path. Raman spectroscopy lets you quantify crystallinity, helping you to adjust cooling rates and process speeds on the spot. The result: consistent performance of semi-crystalline polymers, fewer complaints, and greater competitiveness in high-performance markets.

From process trial to process insight

Extruders simulate real processing conditions, and Raman in-line analytics refine them into a more powerful decision-making tool: faster recipe optimization, consistent results, and confident innovation cycles.

Explore the Tools Behind the Insights

Anton Paar’s Brabender extruders and the Anton Paar Cora 5001 Raman spectrometer each bring their own strengths. Together, they create a powerful system for polymer development.

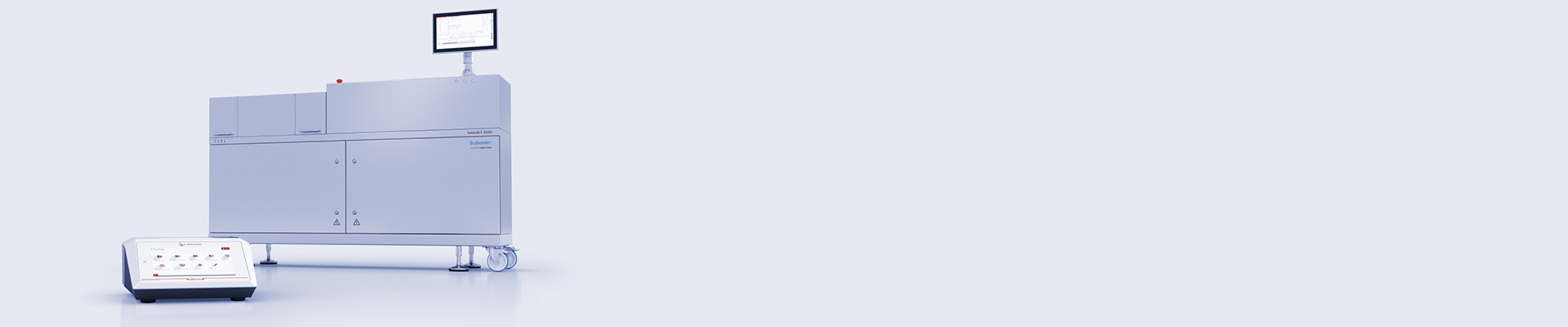

Single- and twin-screw extruders

- Lab- and pilot-scale extruders for exploring new materials and formulations

- Flexible configurations with single- and twin-screw designs

- Precise control over processing parameters (temperature, shear, residence time)

- Ideal for compounding, reactive extrusion, and material testing

Raman spectrometer

- Real-time, non-destructive chemical analysis directly in the melt

- Identifies, e.g., composition, crystallinity, chemical conversion, and filler content

- Compact, robust design tailored for lab and at-line use

- Generates immediate, actionable data that complements extrusion