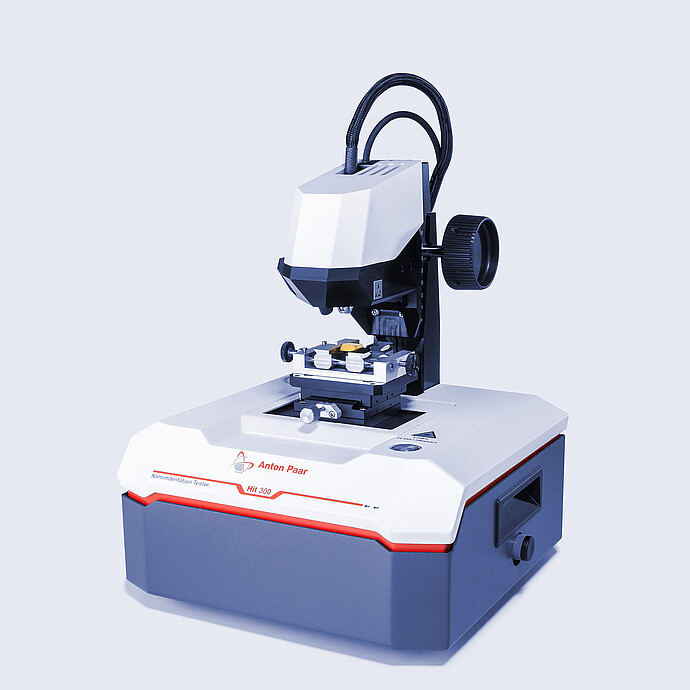

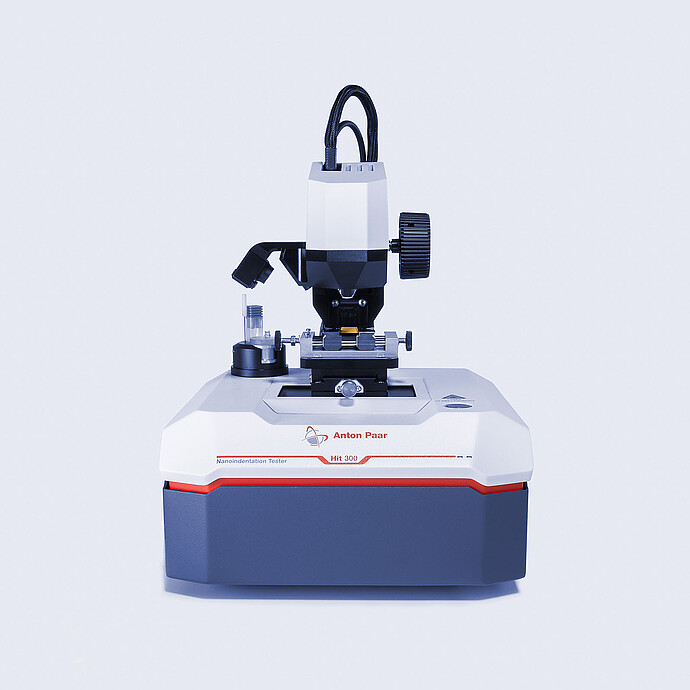

Nanoindentation Tester:

Hit 300

- Simplest-to-use nanoindentation tester on the market

- Less than half the price of comparable instruments

- Active anti-vibration isolation

- 3-year warranty

- Ready to start measuring in 15 minutes

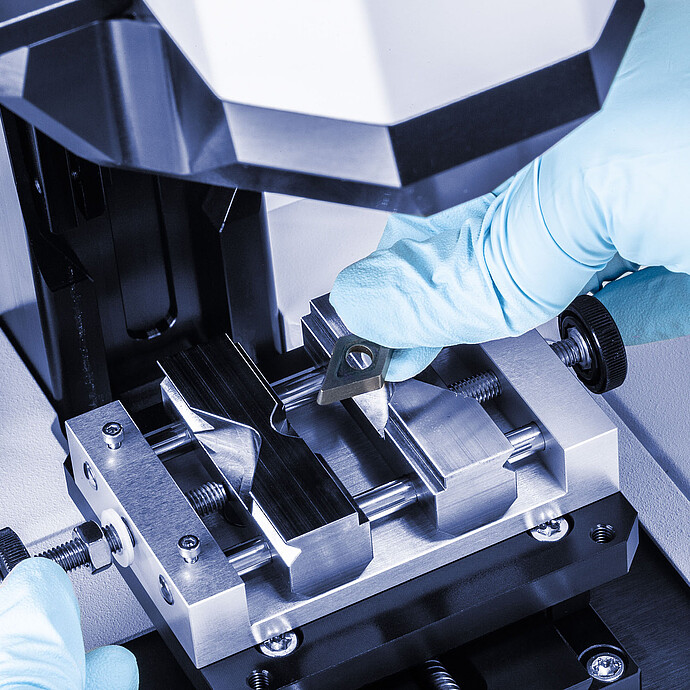

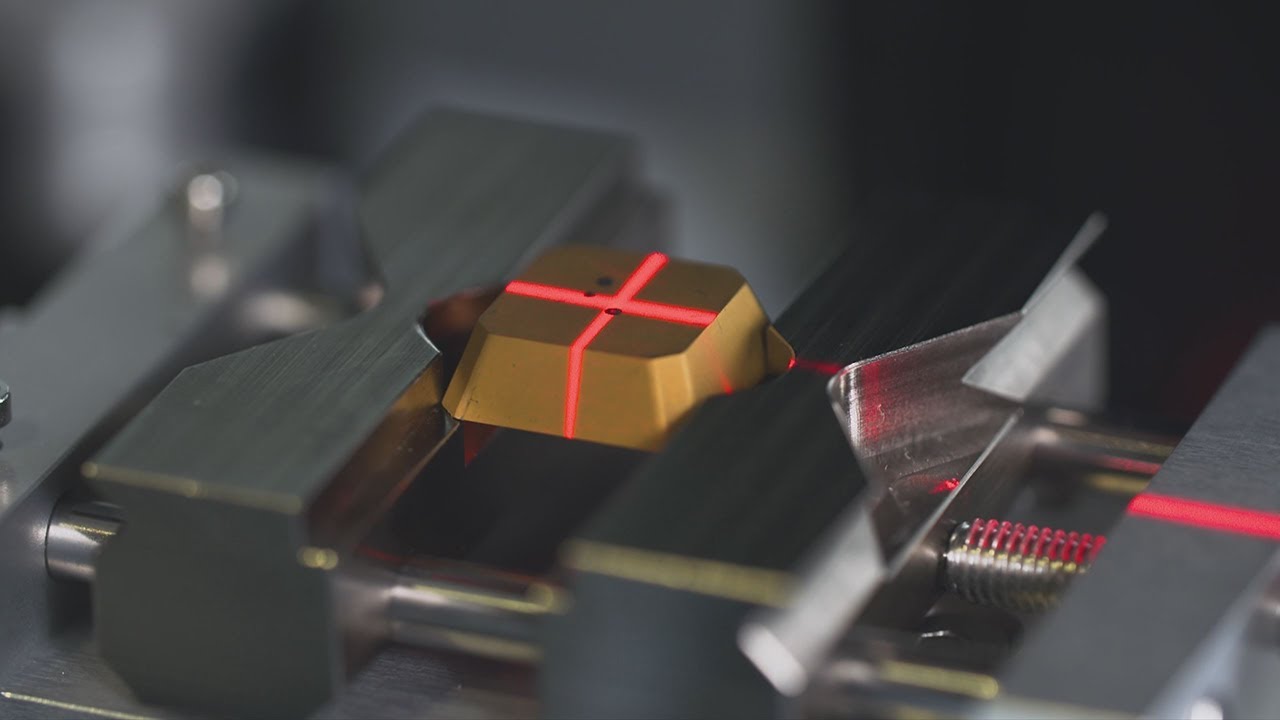

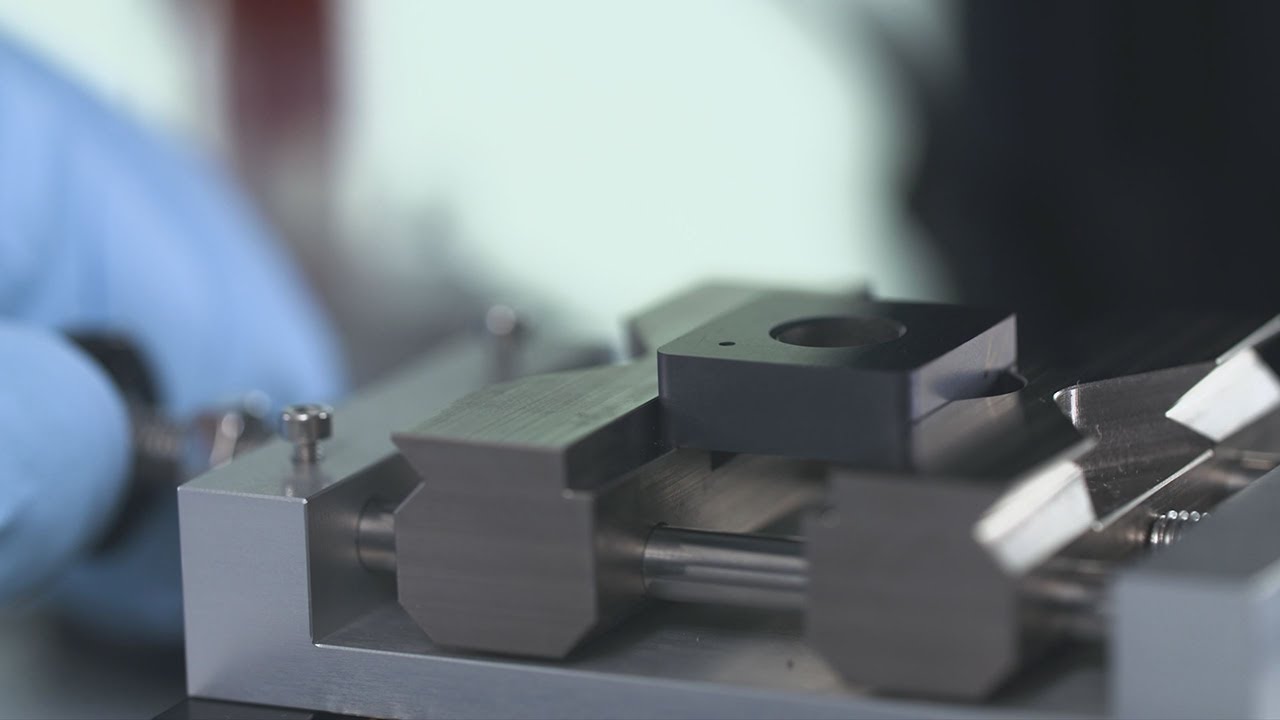

Hit 300 is a premium yet highly affordable nanohardness tester built for every user and every type of environment. The intuitive, automated Hit 300 lets you run 600 measurements per hour, even while you’re away. Active anti-vibration damping ensures accuracy in all environments. A unique 2-laser targeting system delivers <1 mm accuracy when targeting the sample. Designed with functionality in mind: setup takes just 15 minutes, and training to first result takes just 1 hour.

- Get started without being an expert

- Robust design with top surface reference ring

- Step-by-step software workflow

Challenge

Indentation testing is a complex and important method to learn more about material surface properties, which are usually directly related to their performance in an end product. In addition to a certain budget, an expert is necessary to operate the instrument.

Solution

Hit 300 comes with a few features that make indentation testing finally accessible for everyone. The indenter is already mounted, and, if necessary, a calibration can be done in less than 15 minutes. A top surface reference ring protects the indenter from collision and deletes the falsifying influence of thermal drift. The software is intuitive and leads you through the workflow step by step.

Benefit

You finally have the possibility to measure your material in-house. All results are at hand immediately, and every lab technician will be able to operate the instrument.

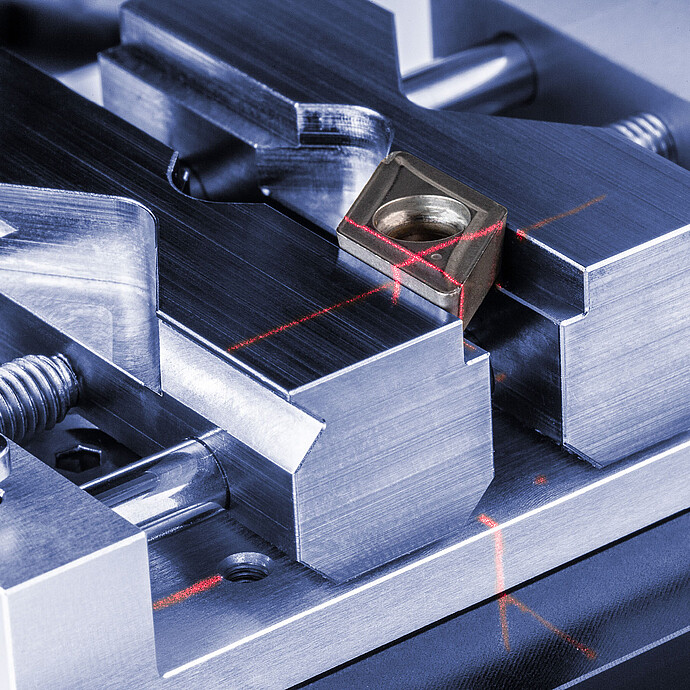

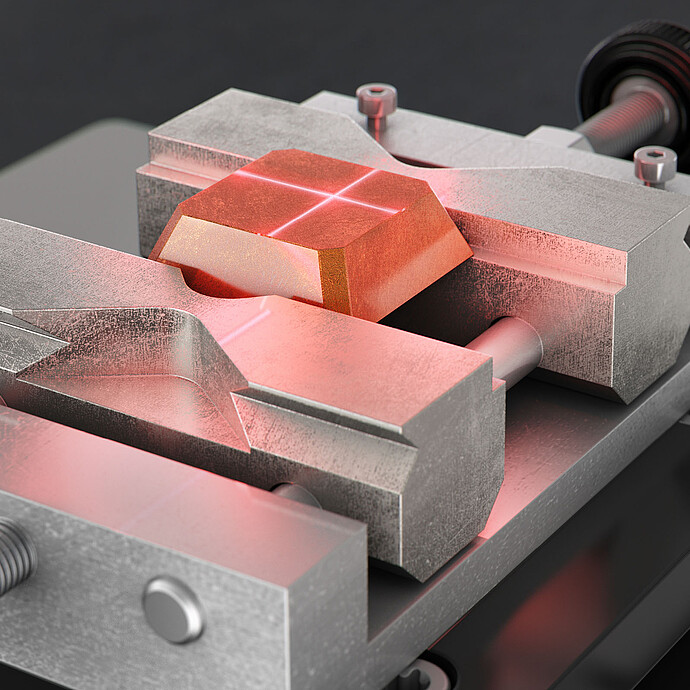

- Target with accuracy <1mm

- No microscope needed

- Most straightforward targeting system on the market

Challenge

Measuring a small sample or reaching a specific measurement area is difficult. Usually, an optical microscope is required, which is expensive and time-consuming.

Solution

Thanks to a unique integrated laser cross, you can directly locate the spot on the sample’s surface where the measurements have to be done.

Benefit

Benefit from a targeting accuracy below 1 mm.

- Active electronic anti-vibration table

- Measure everywhere, from lab to production facilities

- Vibration damping 4 times faster

Challenge

Nanoindentation testing is a very sensitive method, highly affected by mechanical vibrations leading to inaccurate results.

Solution

Hit 300 integrates an active electronic anti-vibration table that damps vibrations 4 times faster than conventional air vibration isolation tables.

Benefit

Install your instrument wherever you need it, from laboratories to production facilities.

- 3-year warranty

- Even for QC in the heavy-duty industry

- Failure-proof design

Challenge

Nanoindentation testers are usually fragile instruments, making them unfit for tasks such as quality control in heavy-duty industry.

Solution

Hit 300 is the most robust nanohardness tester on the market. All parts have been tested with the highest lifetime specifications.

Benefit

We are confident in Hit 300’s ability to stand up to even the toughest jobs, so we offer a 3-year warranty with zero mandatory maintenance.

- Start measuring right after delivery

- Installation in 15 min

- User training within 1 hour

Challenge

Nanoindentation testers are complex instruments. New users typically need 1 to 2 days of intensive training before being able to start measuring their own samples.

Solution

Hit 300 is delivered fully configured, so the installation is done in less than 15 minutes. It is so easy to operate that user trainings usually take only 1 hour.

Benefit

Start measuring on the same day that the instrument is delivered and train other users whenever necessary.

- For small to large samples

- Measure your real products without prior preparation

- 90 mm travel range on the Z axis

Challenge

Nanoindentation testers often limit sample sizes, so some produced parts may not fit into the instrument.

Solution

Thanks to a 90 mm travel range on the Z axis, Hit 300 can measure all small (0.1 mm in height) to big samples (90 mm in height).

Benefit

Measure your products without further preparation.

- 40 mm X motorized table

- Up to 600 measurements/hour

- Unlimited number of user protocols

Challenge

Time is money, and you don’t want to lose time waiting for your nanoindentation measurements to be finished while you can tackle other tasks.

Solution

Hit 300 is equipped with a 40 mm motorized X table in order to perform arrays of measurements automatically. In addition, measurement protocols can be saved, so measurements can be started with a single click.

Benefit

Run up to 600 measurements per hour while you’re away completing other tasks.

- Benchtop instrument

- Less than 1 m² needed

- Flawless operation even in limited spaces

Challenge

It is not always possible to dedicate a large area in the lab to testing equipment, especially in industrial environments.

Solution

Hit 300 is a compact benchtop instrument that can be installed in less than 1 m².

Benefit

The instrument runs perfectly in limited spaces too.

- Compliance with industry standards

- ISO 14577

- ASTM E-2536

Challenge

In order to perform proper and traceable quality control, conformity with established standards is key.

Solution

Hit 300 fully complies with ISO 14577 and ASTM-E2546.

Benefit

Results that are 100 % compliant with industry standards leading to a high-quality product immediately ready for further manufacturing.

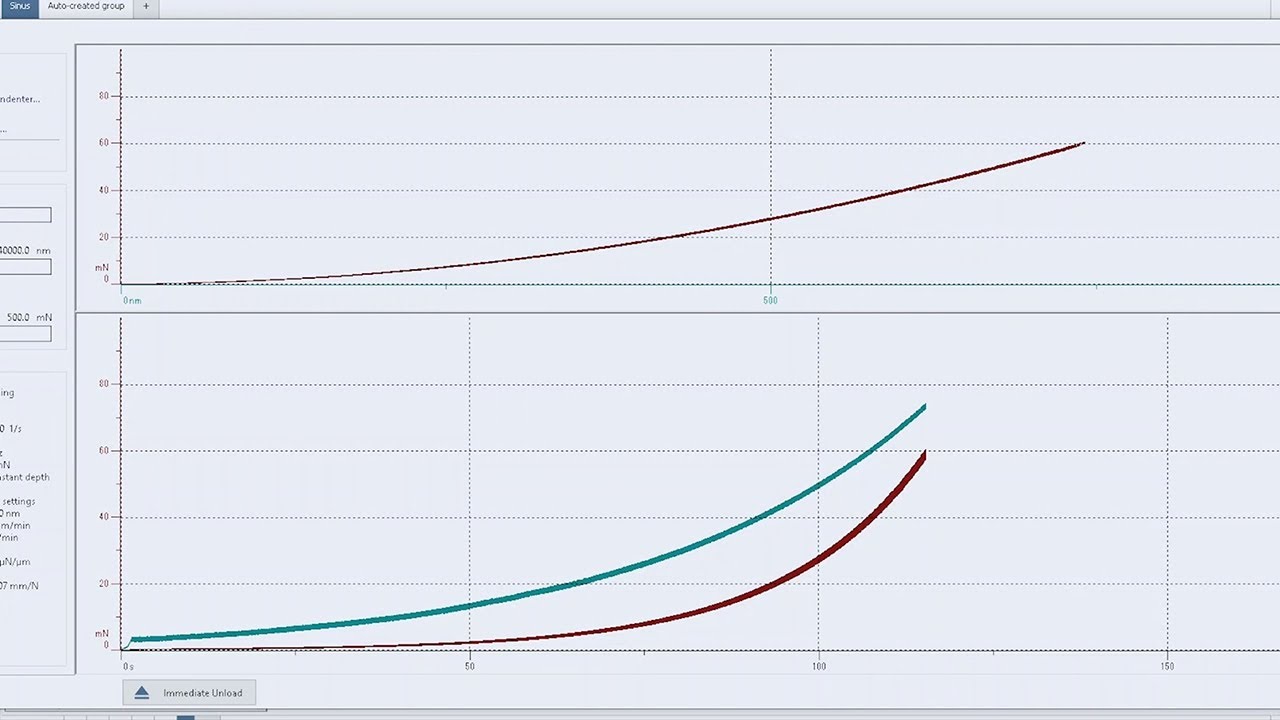

- Dynamic mode (sinus mode) by default

- Investigation of depth-related properties

- Measurement of viscoelastic properties

Challenge

Dynamic mode, also known as “continuous stiffness measurement”, is usually an option dedicated to high-end instruments.

Solution

Hit 300 offers the dynamic mode (sinus mode) by default.

Benefit

Perform investigations of depth-related properties, or measure the viscoelastic properties of your samples without additional expenses.

- Improve your educational skills

- Create tomorrow’s experts

- Nanoindentation testing finally made affordable

Challenge

Nanoindentation is a technique that is important for all future mechanical engineers. Nevertheless, due to high costs, only a few universities can afford such an instrument.

Solution

Hit 300 is the first high-performance nanohardness tester at an entry-level price.

Benefit

All universities are now able to offer their students an instrument to learn and practice nanomechanical testing.

- Teach nanoindentation testing

- Comprehensive material coming with the instrument

- Let students safely practice with the instrument

Challenge

Learning the nanoindentation testing technique is usually a long process, requiring many hours of research and including a certain number of failed tests.

Solution

Our educational package contains everything you need to teach nanoindentation testing, from theoretical presentations to practical tests on samples.

Benefit

Teach nanoindentation testing in an understandable and practical manner.

- Resolution of 0.01 nm to measure thin hard coatings

- Max load of 500 mN to measure thick hard coatings

- PVD/CVD coatings measured with ease

Challenge

Hardness and elastic modulus of coatings can only be measured by indentation testing. Thin coatings (0.5-5 µm) are challenging because of the low indentation depths required to get accurate results.

Solution

Hit 300 uses a well-established technology to offer a versatile instrument. With its amazing depth resolution of 0.01 nm, it is able to accurately measure thin hard films (down to 200 nm), while thick coatings of several µm can be measured thanks to its max load of 500 mN.

Benefit

Measure hardness and elastic modulus of thin to thick hard coatings with remarkable accuracy and simplicity.

- Measure a sample’s mechanical properties in function of depth

- No need to prepare sample cross-section

- Measure the properties of FGM

Challenge

Functional graded materials (FGM) present evolutions of their mechanical properties over depth. They cannot be measured by standard methods.

Solution

The instrument’s dynamic mode measures the evolution of mechanical properties over depths directly from the top surface.

Benefit

Investigate the depth-related properties of your products with no previous sample preparation.

- Measure the viscoelastic properties of your products: E’, E’’, and loss factor (Tan ẟ)

- Measure both coating or bulk polymer materials

- Nanoindentation of polymers

Challenge

Polymers are time-dependent materials, exhibiting both elastic and viscous properties.

Solution

The dynamic mode of Hit 300 measures the viscoelastic properties of polymers by nanoindentation.

Benefit

You can characterize the storage modulus E’, the loss modulus E’’, and the loss factor Tan ẟ of your polymer samples either in coating or bulk format.

- One instrument, various properties

- Measure hardness, elastic modulus, and more properties with a single measurement

- Investigate your bulk materials’ surface properties

Challenge

Hardness and elastic modulus of bulk materials are usually measured with conventional techniques (Vickers, Brinell, tensile tests). This requires multiple instruments and lots of testing time. Tensile tests are also very restrictive in terms of sample geometries.

Solution

Nanoindentation is a technique to determine both hardness and elastic modulus of materials with a single measurement.

Benefit

Measure hardness, elastic modulus, and many other mechanical properties with a single fast measurement.

Technical specifications

| Maximum load | 500 mN |

| Load noise floor [rms] | ≤ 1 μN |

| Load resolution | 0.02 μN |

| Depth range | 200 μm |

| Depth resolution | 0.01 nm |

| Depth noise floor [rms] | ≤0.3 nm |

| Frame compliance | ≤0.3 μm/N |

| Motorized X table travel range | 40 mm |

| Manual Y table travel range | 40 mm |

| Anti vibration table included | Yes, active electronic system |

| Laser indicating indentation position | Crosshair |

| Optional video camera | ≥3x magnification; resolution 5.04 megapixel |

| Dimensions (width x depth x height) | 269 mm x 259 mm x 420 mm |

| Weight | 13,5 kg |

| Standard compliance | ISO 14577, ISO 19278, ASTM E2546 |

Standards

ASTM

ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Applications of indentation and scratch in automotive industry Application Reports

-

Applications of nanoindentation in biology and medicine Application Reports

-

Characterization of diamond-like coatings (DLC, ta-C) from ANTACON Application Reports

-

Comparison of nanoindentation with conventional hardness Application Reports

-

Dynamic mechanical analysis by nanoindentation Application Reports

-

How to deal with roughness in nanoindentation measurements Application Reports

-

Polymer mechanical properties with the Hit 300 nanoindentation tester Application Reports

Consumables

Consumables

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

CERTIFIED FUSED SILICA SAMPLE WITH STUD CERTIFIED SAMPLE FOR ELASTIC MODULUS

BERKOVICH DIAMOND FOR UNHT3/NHT3