Spirits, Liqueurs

Monitoring the alcohol and extract content in spirits and liqueurs is a basic but essential requirement to ensure cost-efficient production and consistent product quality. The solutions for these analyses provided by Anton Paar exactly fulfill these requirements for a wide range of products, from pure distillates and spirits with low extract contents to liqueurs containing high amounts of sugar. Find the measuring instrument that meets your particular needs in the instrument list below – or let us help you find the best solution by contacting us directly.

Anton Paar Products

Alcolyzer Analyzing System

Alcolyzer Liqueur Analyzing System

Alcolyzer Spirits Analyzing System

DMA

Abbemat Juice Station

DMA 1001

DMA 501

Abbemat

L-Cor 8000

L-Cor

L-Cor 4000

L-Com 5500

DSA 5000 M

DMA 4200 M

Alcolyzer M Spirits

Abbemat

Abbemat

SmartRef

DMA HPM

Snap 41

Snap 51

DMA 35 Basic

Multicube 48

L-Cor

L-Cor 6000

Alcohol Monitor

Wine Monitor 5500/5600

Carbo

L-Dens 7300 Petro

L-Dens 7400

L-Dens 7500

L-Rix

L-Sonic 5100

Multiwave 5000

Modulyzer

pH 3101 / pH 3201

DMA 35 Standard

EasyDens

Refractometer

Craft2Craft Spirits

Haze 3001

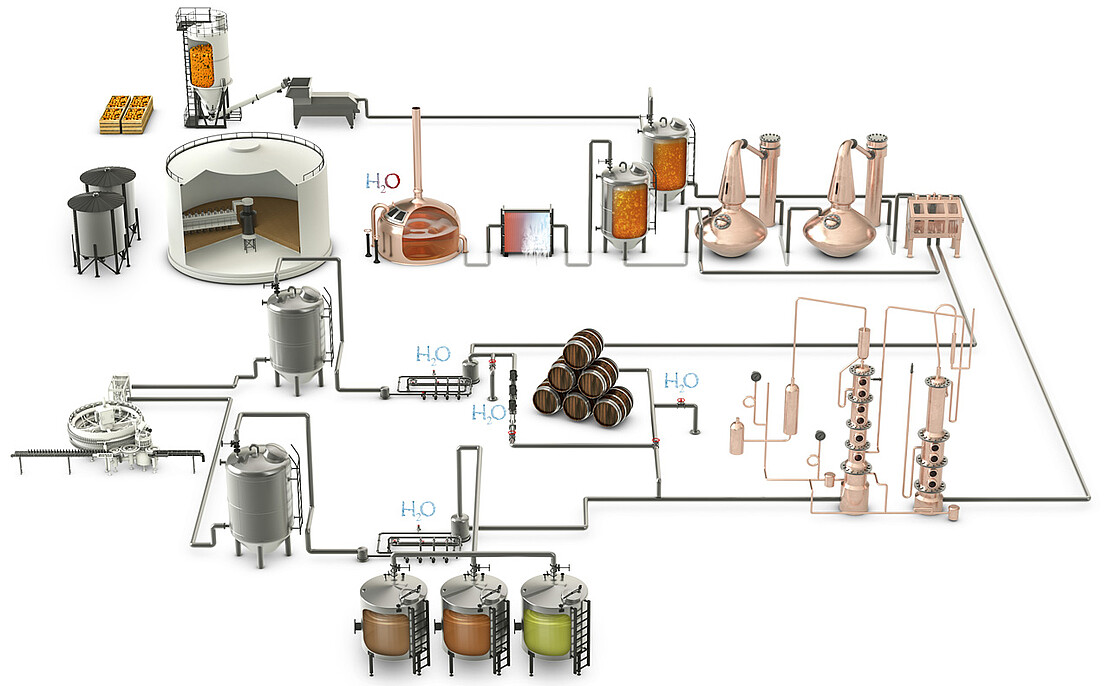

The spirits process

Complete your spirits and liqueurs analysis and measure key parameters from the incoming raw materials to the final quality control of the packaged product. Your benefits:

- Combine over 20 instruments to streamline quality

- Trace multiple parameters from any location in the plant

- Calibration and adjustment at the push of a button

- Global support and service from local specialists

Hover over the dots to learn which instrumentation you can use at this point in your production or to see how you will benefit from measurements at this point.

Wort/juice monitoring

L-Dens 7400 or L-Dens 7500 density sensor

L-Sonic 5100 sound velocity sensor L-Rix 4100/5100/5200 mPDS 5 evaluation unit with Davis 5 softwareWort/juice monitoring

L-Dens 7400 or L-Dens 7500 density sensor

L-Sonic 5100 sound velocity sensor L-Rix 4100/5100/5200 mPDS 5 evaluation unit with Davis 5 softwareSpirits safe monitoring

L-Dens 7000 density sensor series

mPDS 5 evaluation unit with Davis 5 softwareLiqueurs blending

L-Dens 7400 or L-Dens 7500 density sensor

L-Rix 4100/5100/5200 mPDS 5 evaluation unit with Davis 5 softwareBottling and packaging

L-Dens 7400 or L-Dens 7500 density sensor

L-Rix 4100/5100/5200 mPDS 5 evaluation unit with Davis 5 softwareBottling and packaging

L-Dens 7400 or L-Dens 7500 density sensor

L-Rix 4100/5100/5200 mPDS 5 evaluation unit with Davis 5 softwareRaw materials monitoring

- Only raw materials that meet the specifications are used

- Final product quality is ensured right from the beginning

- Optimization of the production process

- Cost-effectiveness is improved by avoiding faulty batches

Wort/juice monitoring

- Considerable energy savings

- Minimized extract/sugar loss

- Increased consistency of the process

- Saves time, energy, water, and costs

- Optimized yield of clear wort

- Clear wort without unwanted trub particles

- Increased mashing efficiency by reduced boil time

Fermentation monitoring

- Optimized fermentation progress ensured

- Consistently high product quality

- Timely action possible to achieve the desired output

- Savings by exact end point determination

- Reduction in laboratory and process time

Spirits safe monitoring

- Consistently high quality

- Distillation control

- Ensure pure product without foreshots or feints

- Only spirits that meet the specifications are released for bottling/maturation/blending

- Highly accurate alcohol measurement

- Ensure proper alcohol taxation

- Omit adulteration of spirits

Spirits safe monitoring

- Consistently high quality

- Distillation control

- Ensure pure product without foreshots or feints

- Only spirits that meet the specifications are released for bottling/maturation/blending

- Highly accurate alcohol measurement

- Ensure proper alcohol taxation

- Omit adulteration of spirits

Spirits blending

- Reduce alcohol give-away in final product

- Ensure proper alcohol taxation

- Optimize maturation process

- Keep consistent quality for final product

- Omit adulteration of spirits

- Timely action possible to achieve the desired product specifications

Liqueurs blending

- Ensure proper product composition

- Keep consistent quality for final product

- Timely action possible to achieve the desired product specifications

Bottling and packaging

- Consistent quality, leading to continuous consumer satisfaction

- Label specifications and legal requirements fulfilled

Rely on cutting-edge technology in the analysis of spirits and liqueurs

More than four decades of expertise in the laboratory and process analysis of raw materials, distillates, liqueurs, and many more products are what make Anton Paar a first-class provider of analytical solutions for inline, at-line, and laboratory analysis in the spirits industry. This experience and our motivation for developing leading technologies and providing new solutions for analytical demands enable you to monitor your entire production process with our solutions.

Combine laboratory and process instrumentation to streamline quality

Individually combine laboratory and process instrumentation to perfectly fit any production requirement ranging from the incoming raw material check to the final quality control of the packaged product. Benefit from reduced out-of-spec production at the lowest possible cost in the shortest time, which enhances your company’s brand and reputation.

Automatic calibration and adjustment procedures simplify your daily work

Calibration and adjustment of analytical equipment can be time consuming. Anton Paar’s laboratory equipment therefore offers intuitive calibration and adjustment procedures, ranging from guided step-by-step instructions to fully automatic calibrations to reduce the efforts required for performance monitoring to a minimum. To benefit from this functionality for process equipment as well, the evaluation software Davis 5 automates the calibration procedures by using reference data provided from the laboratory. In combination, these features are the basis for achieving your goal: correctly determining the alcohol content of liqueurs.

Tailor-made quality control of spirits and liqueurs

Accurate determination of the percentage of alcohol and other quality parameters is essential to ensure excellent product quality. Anton Paar’s product portfolio enables you to choose from a variety of instruments dedicated to spirits and liqueur analysis which results in an efficient combination of devices according to your requirements. Whether the task is to monitor raw materials only or to ensure the specifications of the bottled product by measuring the alcohol content – the choice is yours!

Local specialists provide support and service worldwide

Anton Paar’s global network provides local expertise and service by experienced support staff. Whether the task is to assist with application-related questions concerning the analysis of alcohol content in distilled spirits or extract content in liqueurs, local experts are available on call to ensure your peace of mind. Qualified service personnel guarantee the highest quality of test results over an instrument’s lifespan, which reduces standby times.

Webinars

We offer you a great and constantly growing choice of live webinars and recordings on products, applications, and scientific topics.

View webinarsApplication Reports

Explore our database of application reports and find out how to overcome challenges in your field.

View application reports