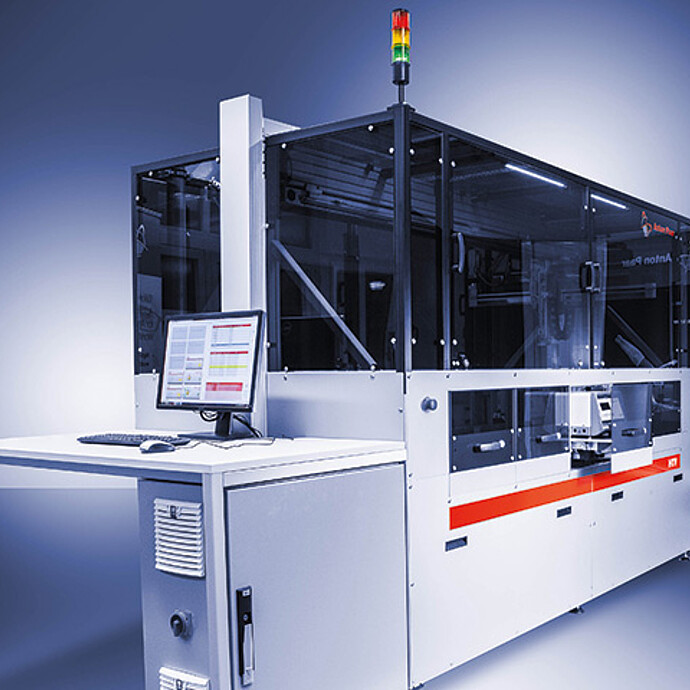

Fully Customizable Laboratory Automation Solution:

HTX

- For multiparameter analysis in automated workflows

- Integrates up to ten analytical instruments and covers sample conditioning, preparation, and measurement

- Fully customizable setup, tailor-made to meet your requirements

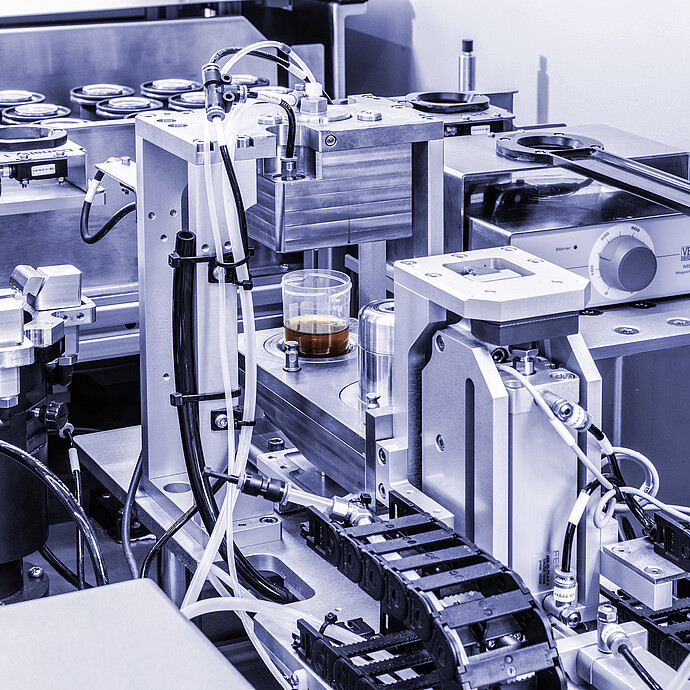

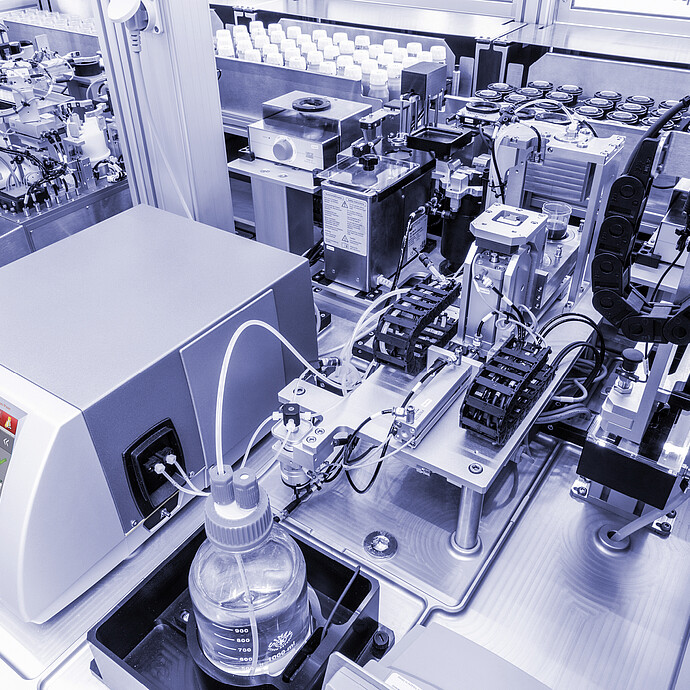

The HTX floor-standing automation platform can integrate up to ten different analytical instruments such as viscometers, density meters, or refractometers for concurrent multiparameter analysis. Its modular concept allows fully customized workflows for sample conditioning, preparation, and measurement.

Key features

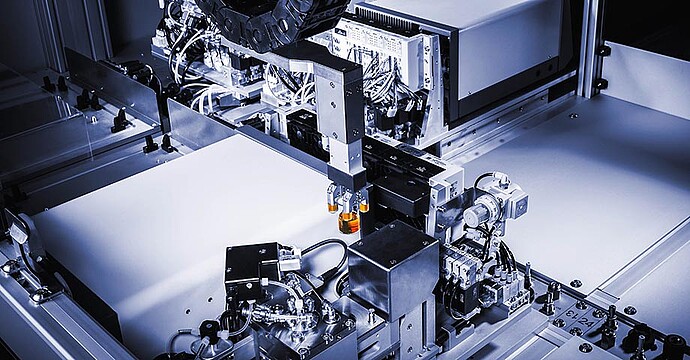

Assemble individual workflows

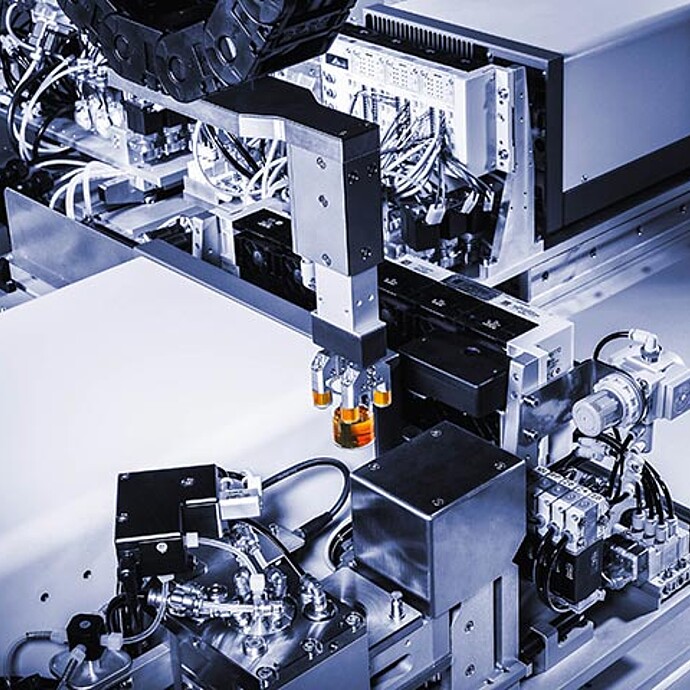

HTX is a fully customizable automation platform for automation of viscometers, density meters, refractometers, polarimeters, rheometers, etc. On request, even third-party analyzers including heating ovens, analyzers with flow cells, balances, etc. can be integrated into the fully automated workflow.

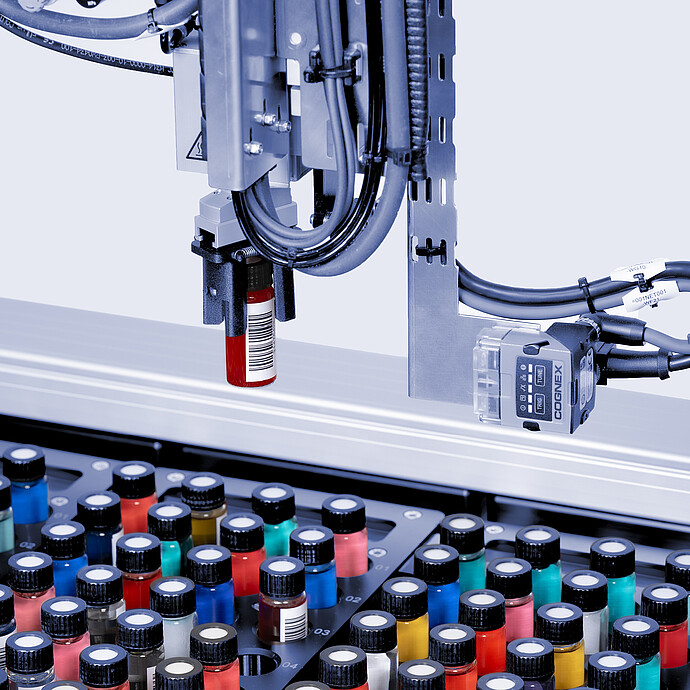

Up to ten slots are available for any combination of lab instruments and/or sample racks. Sample preparation and analyzers work independently of each other and enable multiparameter analysis within one workflow. Downtimes in case of maintenance are minimized due to the multi-module configuration – just redirect measurements to another slot while servicing.

Simplify process control

With the self-explaining and easy-to-use control software for sample and workflow management the samples can be managed by using job lists.

HTX offers a broad variety of notification services (e.g. text messages or email) to keep you informed and connected to your measurements everywhere at any time.

Automation that depends on current needs – introduce priority samples, at any time.

Communicate safely

HTX works with standard industry protocols such as PROFINET, Ethernet, CANOpen, or Profibus and is fully integrated in the laboratory environment via LIMS integration supporting file transfer, database, and Ethernet.

HTV: High Throughput Viscometer based on HTX

HTV is a ready-made configuration based on the HTX platform which can be equipped with up to eight SVM-type viscometers. It processes up to 2500 samples per day using up to four sample racks with 96 vials.

The measuring devices are cleaned fully automatically and the recalibration with standard oils is also performed periodically and fully automatically. HTV complies with the ASTM D7042 standard and is fit for applications such as used oils, lube oils, fuels, chemicals, and cosmetics.

How ideas take shape

Anton Paar offers modular solutions which allow you to stay flexible and adapt your system to future requirements. Anton Paar’s global sales and service network is close to you from the project definition to execution and commissioning, and offers comprehensive training, support, and individual maintenance and service.

Technical specifications

| Dimensions (W x D x H) | 2760 mm x 1600 mm x 2560 mm |

| Weight | 800 kg net weight, 1200 kg with 6 modules |

| Mains supply | 400 VAC, 16 A, 50/60 Hz, 11 kW with 6 modules |

| Media interfaces | 3x solvent (toluene, ethanol, isopropanol), compressed air |

| Waste disposal | Drain for liquids, waste bin for solids, ventilation for fumes |

| Communication interface | Ethernet |

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty