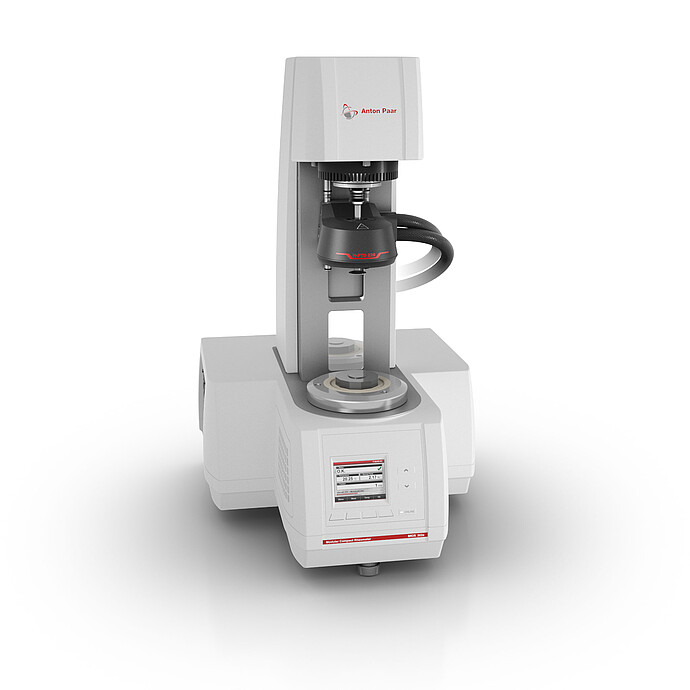

Modular Compact Rheometer:

MCR 102e/302e/502e

- Your entry ticket into the world of QC testing and rheological product development, upgradeable with sample-adaptive controllers

- EC motor technology based on 25 years of expertise and market leadership with a torque range from 2 nNm to 200 mNm

- Normal force measurements up to 50 N

The new MCR Evolution series is the result of consistent thinking and rethinking, of continuous development based on decades of experience and the feedback of more than 10,000 satisfied customers. The combination of innovative and thousandfold field-proven technology with the modular design represents the benchmark in its class. With 200+ accessories the MCR Evolution rheometer series gives you endless possibilities for rheological investigations and material characterization. Experience sophisticated rheological research and advanced QC testing like never before.

Key features

The best now better: the new MCR Evolution series

For more than 25 years we have continuously extended our portfolio in close collaboration with our most important innovation driver, YOU, our highly valued customers and rheometer users. We are now proud to present the new MCR Evolution series: rheometers that push your work one step ahead.

The benefits of the new MCR Evolution series

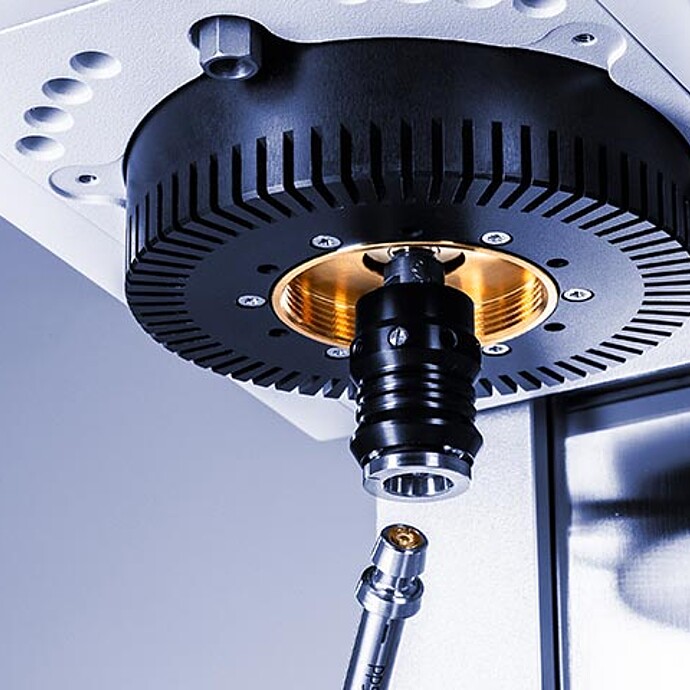

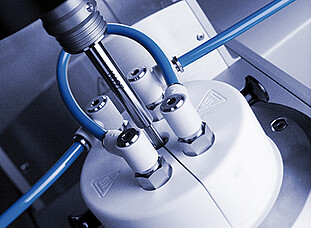

- The fastest one-hand coupling and decoupling of measuring geometries in just one second – even at extreme temperatures (-160 °C to 1000 °C): Novel quick-connect mechanism

- Precisely measure even low-viscosity samples with our entry-budget model: Higher sensitivity (from 7.5 nNm to 2 nNm)

- Stable results even for long-term measurements with low torque: Improved thermal management within the EC motor starting from MCR 302e

- More space for sample handling and exchange of accessories: Extended working height starting from MCR 302e

- The only device on the market with a trimming mirror for a 360° view of the sample with no blind spots, which avoids sample preparation errors and leads to highly reproducible results.

- Detection of any sample behavior change even at the shortest time scales: Reproducible duration of each measuring point down to 1 ms

- Full pharma compliance: The best pharma package for the RheoCompass software (21 CFR Part 11, full data integrity according to ALCOA+)

Takes work off your hands: Unique motor and sample-adaptive controller technology

The MCR Evo series builds on 25 years of research, development, and constant improvement. This results in technology which pushes the boundaries of rheometry. The combination of the EC motor (Permanent Magnet Synchronous Motor) using a high-precision air bearing with active thermal management, integrated normal force sensor, and a high-resolution optical encoder, for example, allows rheological measurements at the lowest torques ever. The unique sample-adaptive controllers for measurement in rotation (TruRate™) and oscillation (TruStrain™) work for 99 % of all samples and measurements “out of the box” with the perfect combination of speed and accuracy – save time and nerves and even get better data at the same time!

Excellence in every component and every work step

After decades in the field, Anton Paar understands and anticipates what is required for outstanding rheological analysis. With this knowledge in mind, we designed every component and created every handling step to be part of a smooth and intelligent whole:

- The patented Toolmaster™ technology automatically recognizes measuring systems

- One-hand exchange of measuring systems due to the QuickConnect coupling

- T-Ready™ detects sample temperature equilibration in real-time

- The TruGap™ feature detects the real measuring gap

- The trimming mirror gives you a 360° view of the sample and thus supports high measurement repeatability. And many more

Choose from more than 100 test templates, set report filters, and use remote control

The intuitive RheoCompass software offers predefined as well as customized test templates and analysis definitions. Furthermore, it is possible to export your rheological data and generate reports. Data can easily be filtered by e.g. year, batch number, or operator, and displayed within seconds. Due to the Ethernet connection, the rheometer can be remote-controlled from anywhere via the company network. Gap setting, adjustments, and tests can also be started directly from the MCR rheometer, minimizing annoying switches between the computer and the device, e.g. during sample preparation.

Unlimited possibilities: add one of more than 200 accessories

Whatever your rheological applications are and will be in the future – Anton Paar rheometers are quickly and easily adapted to meet your needs. Their flexibility makes them the most cited instruments in scientific publications on rheological investigations. An extensive range of application-specific accessories is available to extend the rheometer’s capabilities, including DMA measurements, extensional rheology, rheo-optics (e.g. microscopy and Raman spectroscopy), magneto- and electrorheology, dielectric spectroscopy, interfacial rheology, UV curing, pressure- and humidity-dependent rheology, tribology, and many more. A wide range of temperature accessories allow you to apply and control temperatures from -160 °C to 1000 °C.

Your partner for special applications and customized solutions

With the special model MCR 502e Power you have the highest available torque of 300 mNm and highest available normal force of 70 N at your fingertips. This means you can perform fatigue- and heating-controlled stress tests on asphalt mixtures, for example.

Based on decades of experience in rheometry and rheology, Anton Paar can make nearly everything possible. We develop and supply customized products for all kinds of specific applications. With our in-house production in Austria and a dedicated R&D team just next door, we develop and supply customized products for all kinds of specific applications. Don’t hesitate to contact us in order to discuss your requirements and to find a customized solution for your measurement task.

Technical specifications

| Technical Data | Unit | MCR 102e | MCR 302e | MCR 502e Power |

| Bearing design | - | Air, fine-pored carbon | ||

| Motor design | - | Electronically Commutated (EC) - Permanent Magnet Synchronous Motor | ||

| Displacement transducer design | - | High-resolution optical encoder | ||

| Normal force measurement design (US Pat. 6167752, 1996) | - | 360 ° capacitive sensor, non-contacting, fully integrated in bearing | ||

| Active thermal management of bearing and normal force sensor | - | No | Yes | Yes |

| Working modes | - | Combined Motor Transducer (CMT) | ||

| Minimum torque (rotation) | nNm | 5 | 1 | 100 |

| Minimum torque (oscillation) | nNm | 5 [1] | 0.5 | 50 |

| Maximum torque | mNm | 200 | 230 | 300 |

| Minimum angular deflection (set value) | µrad | 0.5 | 0.05 | 0.05 |

| Maximum angular deflection (set value) | µrad | ∞ | ∞ | ∞ |

| Minimum angular velocity [2] | rad/s | 0 | 0 | 0 |

| Maximum angular velocity Maximum speed | rad/s 1/min | 314 3000 | 314 3000 | 220 2100 |

| Minimum angular frequency [3] | rad/s | 10 -7 | 10 -7 | 10 -7 |

| Maximum angular frequency [4] Maximum frequency | rad/s Hz | 628 100 | 628 100 | 628 100 |

| Normal force range | N | -50 to 50 | -50 to 50 | -70 to 70 |

| With Exposed Support Plate (WESP / Space) [5] | - | No | Optional | No |

| Without Support Plate (WSP) | - | No | Optional | No |

| Dimensions (W x H x D) | mm | 444 x 678 x 586 | 444 x 733 x 586 | 444 x 753 x 586 |

| Weight | kg | 42 | 46 | 47 |

| Additional Device Features | ||||

| Device display with remote control of software (decoupled from measuring sensor for mechanical and electromagnetic interference prevention) | - | Yes | Yes | Yes |

| Direct strain/stress controller | - | Yes | Yes | Yes |

| TruRate™ / TruStrain™ (sample adaptive controller) | - | Optional | Yes | Yes |

| Raw data (LAOS, waveform) | - | Optional | Yes | Yes |

| Normal force profiles (set and read) | - | Yes | Yes | Yes |

| Velocity profiles, tack, squeeze | - | Optional | Yes | Yes |

| Automatic gap control/setting (AGC/AGS) | - | Yes | Yes | Yes |

| Electronic trim lock for measuring geometry | - | Yes | Yes | Yes |

| Fully automatic temperature calibration | - | Yes | Yes | Yes |

| TruGap™ (permanent control of the real measuring gap) (US Pat. 6499336, 2000) | - | Optional | Optional | Optional |

| T-Ready™ [6] (detection of sample temperature equilibrium time) (US Pat. 8904852, 2011) | - | Yes | Yes | Yes |

| Toolmaster™ (measuring geometries and accessories, storing of zero-gap) (US Pat. 7275419, 2004) | - | Yes | Yes | Yes |

| QuickConnect Coupling for measuring geometries (one-hand operation, screwless) | - | Yes | Yes | Yes |

| Trimming mirror (360° blind sample spot prevention) | - | Yes | Yes | Yes |

| Three-point support of device (three robust feet for tool-free one hand alignment) | - | Yes | Yes | Yes |

| Three-point support for mounting of measuring cells (wobble prevention, no misalignment after changing of cells) | - | Yes | Yes | Yes |

| Maximum temperature range | °C | -160 to +1000 | -160 to +1000 | -160 to +1000 |

| Maximum pressure range | bar | up to 1000 | up to 1000 | up to 1000 |

| Ready for DMA in torsion and tension | - | Yes | Yes | Yes |

| Ready for tribology | - | Yes | Yes | Yes |

| Ready for powder flow and shear rheology | - | Yes | Yes | Yes |

[1] 2 nNm with activated TruStrain™ option

[2] In controlled shear stress (CSS) mode. In controlled shear rate (CSR) mode depending on measuring point duration and sampling rate.

[3] Theoretical value (duration per cycle = 2 years)

[4] Higher frequencies are possible using multi-wave functionality (942 rad/s (150 Hz) or even higher, depending on measuring system and sample)

[5] Enlarged working space underneath the support plate (flange) [6] Depending on used temperature device

Standards

ASTM

DIN

DIN EN ISO

EN

ISO

Pharmacopoeia Europe (Ph. Eur.)

U.S. Pharmacopoeia (USP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

A Multi-Task Rheological Test for Characterization of Adhesive Applications Application Reports

-

Calculation of the Critical Shear Rate in a Cylinder Measuring System Application Reports

-

Catalyst-Enhanced Curing of Two-component Epoxy Coatings Application Reports

-

Combined rheological methods - From rheo-optics to magneto-rheology and beyond Application Reports

-

Comparison of Polyethylene PE Melts Using Frequency Sweeps Application Reports

-

Determination of Humidity-Dependent E-Moduli Application Reports

-

Determination of Mechanical Properties of Balance Springs Application Reports

-

Determination of Tack Using Different Adhesive Substances and Substrates Application Reports

-

Determination of Temperature-Affected Polymer Softening Application Reports

-

Do You Dare to Replace Dairy? The Flow Behavior of Plant-Based Cream Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

-

E-Book - Field Guide to Food Powder Characterization Application Reports

-

E-Book - Field Guide to Pharmaceutical Powder Characterization Application Reports

-

E-Book | Automotive tribology: Analyzing greases, oils and components Application Reports

-

Foam Alone: How to Generate and Analyze Foams in the Powder Flow Cell. Application Reports

-

Food Characterization Application Reports

-

Granulation and Drying: the Choice of Excipients Matters Application Reports

Similar products

Consumables & Accessories

Consumables & Accessories

Accessories

Accessories

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

TRANSPORT PROTECTION MCR XX2

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

DUST COVER MCR RHEOMETERS SUITABLE FOR MCR 52/72/92/102/302/102e

MCR 102e/302e/502e MCR 102e | MCR 302e

SPLASH GUARD FOR MCR 52/102/302/102e/302e

MCR 102e/302e/502e MCR 102e | MCR 302e

DUST COVER MCR RHEOMETERS SUITABLE FOR MCR 502/702/302e/502e/702e

MCR 102e/302e/502e MCR 302e | MCR 502e Power

SPLASH GUARD FOR MCR 502/702/502e/702e

MCR 102e/302e/502e MCR 502e Power

ADAPTER TD/8P-TD/18P MCR XX2 TO MCR X2

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

P-PTD 220/AIR FOR MCR xx2 / MCR xx2e PELTIER TEMPERATURE DEVICE (PLATE)

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- plate with active Peltier temperature control (heating/cooling)

- for cone/plate and parallel plate measuring geometries

- with built-in fan for air counter-cooling

- with universal plate holder (screw-on thread) for use of measuring plates (also disposable) and other accessories

- with Toolmaster for automatic tool recognition and configuration

- installation in the rheometer through three-point support without the risk of misalignment

- maximized torsional stiffness due to constructional torque support

Optical accessory for MCR:

Rheometer-Infrared Spectrometer Adapter

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for structure analysis and rheo optics

- Lets you connect your infrared spectrometer with an MCR rheometer

- Investigates the chemical composition and rheology

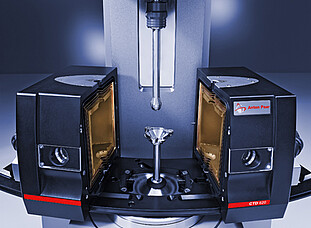

Rheometer-Raman Setup:

MCR Evolution & Cora 5001

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Rheology meets Raman spectroscopy

- See how Raman spectra change during rheological investigations

- Better understand changes in chemical functionality and microstructure

MEASURING PLATE PP50/P2 D:

50 mm, PROFILED: 1X0.5

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Accessory for MCR:

DMA Measuring Systems

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- For dynamic mechanical analysis (DMA) in bending, tension, torsion, and compression

- Solid rectangular fixtures, three-point bending geometries, cantilevers, compression systems

- Compatible with MCR 702e MultiDrive

DISPOS. LOWER MEASURING PLATE L-PP08/D/AL/CTD

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Temperature Control for MCR:

Peltier Systems

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Effective and convenient heating and cooling

- Temperature control with minimized temperature gradients from -50 °C to 220 °C

- Modular system for combination with Rheo-Optics accessories

- For cone-plate, parallel-plate, and cylinder measuring systems

MEASURING PLATE PP50/S D:

50 mm, SANDBLASTED

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Accessory for MCR:

Magneto-Rheological Device

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

MEASURING PLATE PP20 D:

20 mm

MCR 102e/302e/502e MCR 102e

Accessory for MCR:

Electro-Rheological Device

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Additional Parameter Settings”

- Characterization of electrorheological fluids

- Electric field of up to 12.5 kV can be applied

MEASURING PLATE PP25/P2 D:

25 mm, PROFILED: 1X0.5

MCR 102e/302e/502e MCR 102e

Accessory for MCR:

Dielectric Spectrometer

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Combine rheology and dielectric spectroscopy

- Study a material’s response to an applied electric field

- Gain information on a material’s structure and behavior

MEASURING CONE CP40-2 D:

40 mm; ANGLE 2°

MCR 102e/302e/502e MCR 102e

Accessory for MCR:

Rheo-SALS

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Structure Analysis and Rheo-Optics”

- Small-angle light scattering (SALS) combined with rheology

- For investigating shear-dependent shape and orientation of microstructure

- Temperature range from -20 °C to 300 °C

MEASURING CONE CP50-0.5 D:

50 mm; ANGLE 0.5°

MCR 102e/302e/502e MCR 102e

Optical Accessory for MCR:

UV Light Curing System

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for additional parameter setting

- For the investigation of UV-curing reactions

- Simultaneous characterization of rheological behavior and UV-light-initiated curing

- Built-in temperature control

MEASURING PLATE PP12 D:

12 mm

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Accessory for MCR:

Interfacial Rheology System

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for extended material characterization

- Highly precise studies of the flow properties of interfacial layers

- Comprehensive rheological investigations of emulsion and foam stability

INSET I-PP50/CU/CX D:

50 mm; COPPER ALLOY, COATED

MCR 102e/302e/502e MCR 102e

Accessory for MCR:

Rheo-Microscope

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Combining light microscopy with rheological measurements

- Automated image/video recording during measurements

- Lens magnifications: 5x, 10x, 20x, 50x

- Modules for polarization and fluorescence microscopy available

- Temperature range from -20°C to +300 °C

MEASURING CONE CP40-1 D:

40 mm; ANGLE 1°

MCR 102e/302e/502e MCR 102e

Accessory for MCR:

Immobilization Cell

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Additional Parameter Settings”

- Immobilization kinetics of paper coatings in real-time

- Liquid temperature control

Accessories for MCR:

Ball Measuring System & Building Material Cell

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessories for extended material characterization

- Measuring systems for large-particle rheology

- Designed for building materials, food products, slurries, and sludges

- Built-in temperature control

Temperature Control for MCR:

Liquid Temperature Devices (LTD)

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- For measurements at constant temperatures from -30 °C to +180 °C

- For parallel-plate, cone-plate, concentric cylinder, and double-gap measuring geometries

Temperature Control for MCR:

Electrical Temperature Devices (ETD)

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Electrically heated temperature control devices available for MCR rheometers

- For high-temperature measurements up to 400 °C

- For parallel-plate, cone-plate, concentric cylinder, and double-gap measuring geometries

ACTIVATED CARBON FILTER FOR DRYPOINT AIR DRYER

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

MCR Rheometer Setups for:

Powder

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accurate powder analysis with the powder flow cell and shear cell

- True powder rheology to analyze bulk solids in any state, from fluidized to consolidated powders

- Wide range of dedicated powder measurement methods for quality control and R&D

Accessory for MCR:

Humidity Option

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Additional Parameter Settings”

- Control the impact of the relative humidity on a material’s rheological behavior

MEASURING PLATE PP15 D:

15 mm

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Temperature Control:

Convection Temperature Devices (-160 °C to +1000 °C)

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- For temperature-controlled rheological and DMA measurements on melts, solids, films, and fibers from -160 °C to 1000 °C

- Homogeneous temperature distribution for accurate & stable results

- For MCR measuring systems: parallel-plate, cone-plate, DMA in torsion or extension, controlled relative humidity, and more

Accessory for MCR:

Polarized Light Imaging

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Structure Analysis and Rheo-Optics”

- For visualization of shear stress in the sample

- For parallel-plate and cone-plate systems and a temperature range from -20 °C to 300 °C.

Accessory for MCR:

Particle Imaging Velocimetry

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Structure Analysis and Rheo-Optics”

- For visualization of flow fields

Accessory for MCR:

Rheo-SANS/SAXS

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Structure Analysis and Rheo-Optics”

- Small-angle scattering for nanostructure analysis

- Temperature range from -50 °C to +300 °C

Accessory for MCR Temperature Devices:

Low Temperature Options

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Combinable with electric and convection temperature devices

- Choice of solutions for different low temperature requirements: down to -40 °C, -90 °C, or -160 °C

- Toolmaster functionality for automatic system configuration and error-proofing

SPATULA

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

Temperature Control:

Peltier Systems with TruGap™

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- TruGap™ measures the real gap size to ensure accurate measurements even if the measuring temperature changes

- No loss of accuracy: set the zero-gap at any temperature you want

- Reduces waiting times: T-Ready™ detects when temperature equilibrium is reached and starts the test automatically

Universal Extensional Fixture and Sentmanat Extension Rheometer:

UXF & SER

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- For extensional rheology investigations

- Strain- or stress-controlled extensional and DMA tests with the UXF

- Extensional tests at high torques with the Sentmanat Extension Rheometer

Pressure Cell

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- For investigation of the effect of pressure on rheological properties

- Unique pressure range of up to 1000 bar

- Choose between gas or liquid pressurization

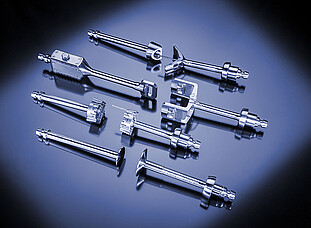

Accessory for MCR:

Rheometer Geometries

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Wide range of measuring systems for RheolabQC and the MCR rheometer series

- Concentric cylinder, double-gap, cone-plate, and parallel-plate systems, vane geometries and spindles, Krebs spindles

- Customized solutions upon request

Accessory for MCR and RheolabQC:

Flexible Cup Holder

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Accessory for “Extended Material Characterization"

- Holds, for example: paint cans, yogurt cups, other containers

- Can be combined with stirrers, concentric cylinder geometries, and a Pt100 temperature sensor

MCR Tribology Cell:

T-BTP

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Based on the ball-on-three-plates measuring principle

- Excellent temperature control from -160 to +600 °C

- Adjustable spring stiffness in z-direction

- Normal force range expanded down to 0.1 N

MCR Tribology Cell:

T-PTD 200

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Based on the ball-on-three-plates measuring principle

- Excellent temperature control from -40 °C to +200 °C

- Sliding speed control of up to 3.3 m/s

- Rolling bearing attachment optional

MCR Tribology Cell:

T-PID/44

MCR 102e/302e/502e MCR 102e | MCR 302e | MCR 502e Power

- Based on the pin-on-disc measuring principle

- Excellent temperature control from -30 °C up to +200 °C

- Adjustable spring stiffness in z-direction

- Sliding speed control of up to 2.3 m/s