Beer, FABs

Comprehensive beer analysis from one source

Anton Paar is the world’s first full-range supplier for your beer analysis. High-end technology meets global service for your perfect beer analysis.

Anton Paar Products

EasyDens and SmartRef Combo Beer

Alcolyzer Analyzing System

Alcolyzer Beer Analyzing System

Alcolyzer Beer Analyzing System 1001

Alex 500

DMA

Flex-Blend 3000 Series

The Flex-Blend 7000 Series

CboxQC

L-Cor 8000

L-Cor

L-Cor 4000

Alcolyzer M Beer

SmartRef

CarboQC ME

PFD

Brabender FarinoGraph

DMA 35 Basic

L-Cor

L-Cor 6000

Beer Monitor 5500/5600

Extract/Original Extract/Plato Monitor

Fermentation Monitor

Carbo

Oxy

L-Rix

L-Dens 2300

Multiwave 5000

Animo

PBA 1001 Beer

PBA 5001 Beer

pH 3101 / pH 3201

CarboQC

OxyQC

Lovis 2000 M/ME

EasyDens

Craft2Craft Beer

ALAB 5000

TPO 5000

Haze 3001

Brabender MT-CA

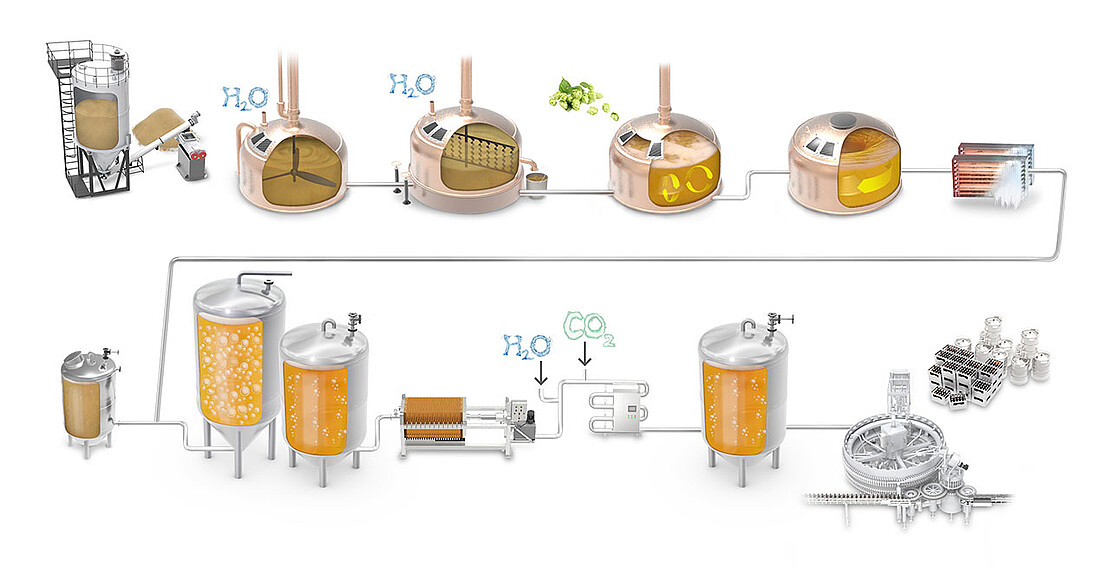

The beer process

Complete your beer analysis and measure key parameters from the incoming raw materials to the final quality control of the packaged beverage. Your benefits:

- Combine over 25 instruments to streamline quality

- Trace 15+ parameters from any location in the plant

- Calibration and adjustment at the push of a button

- Over 40 years of expertise in the beer industry

- Global support and service from local specialists

Hover over the dots to learn which instrumentation you can use at this point in your production or to see how you will benefit from measurements at this point.

Wort monitoring: Lauter tun and mash filter

DMA 35 portable density meter Alex 500 alcohol and extract meter Beer analyzing system DMA benchtop density metersWort monitoring: Lauter tun and mash filter

L-Dens 7400 or L-Dens 7500 density sensor L-Sonic 5100 sound velocity sensor mPDS 5 evaluation unit with Davis 5 softwareWort monitoring: Kettle

L-Dens 7400 or L-Dens 7500 density sensor

L-Sonic 5100 sound velocity sensorFermentation monitoring

Fermentation monitor 5100Beer monitoring: Filtration, blending and carbonation

Beer analyzing system DMA benchtop density meters PBA Packaged Beverage Analyzer Portable CO₂ and O₂ meters Turbidity meter Haze 3001 Rolling-ball viscometer: Lovis 2000 M/MEBeer monitoring: Filtration, blending and carbonation

Beer Monitor 5500 or 5600 Oxy dissolved oxygen sensor Inline CO₂ sensors Color sensor: L-Col 6100 Flex-Blend Series Data recording software: Davis 5Lauter tun and mash filter

- Considerable energy savings

- Substantial time savings

- Minimized extract losses

- Stable brewhouse operations ensured

Kettle

- Reduced boil time

- Considerable energy savings

- Increased brewhouse efficiency

- Clear wort without disturbing particles

Whirlpool

- Clear wort without unwanted trub particles

- Optimized yield of clear wort

- Increased efficiency

- Saves time, energy, and costs

Wort cooler

- Maximized efficiency

- Conscious use of energy

- Time and cost savings

- The direct route to great beer

Fermentation tank

- Excellent yeast performance maximizes the yield

- Optimized fermentation progress ensured

- Consistently high product quality

- Timely action possible to achieve the desired output

Filtration, blending and carbonation

- Consistently high beer quality

- Precise blending ratios and carbonation values

- Efficient use of valuable ingredients

- Ensures oxygen-free beer enters the storage tank

Storage tanks

- Consistent quality, leading to continuous consumer satisfaction

- Timely action possible to achieve the desired product specifications

- Label requirements safeguarded

Yeast propagation

- Consistent yeast propagations

- Consistency in pitches and fermentation times

Aeration monitoring

OxyQCBeer monitoring: Bottling / filler

Beer Monitor 5500 or 5600 Oxy dissolved oxygen sensor Color sensor: L-Col 6100 Animo: Modular beer analysis system Data recording software: DAVIS 5Bottling / filler

- Consistent product quality with minimal variations in packaging

- Assurance of extended shelf life

- Fulfilment of legal requirements

Mash tank

- Optimization of the production process

- High-quality end products

- Required actions possible in time

- Time- and cost-effectiveness ensured

Combine over 25 instruments to streamline quality

Choosing from more than 25 industry-specific instruments, you can individually combine laboratory and process instrumentation to perfectly fit any production requirement. The result: reduced out-of-spec production at the lowest possible cost in the shortest time, enhancing your company’s brand and reputation.

Over 40 years of expertise in the beer industry

Anton Paar’s beverage analyzing systems are the result of more than 40 years of expertise in inline, at-line and laboratory beverage analysis. Based on thousands of samples, the measuring portfolio includes first-class instruments for continuous, accurate and safe measurement of key quality parameters such as alcohol, extract, dissolved CO₂ and O₂, pH, and many more. Choose leading technologies to support you – from the incoming raw material check to the final quality control of the packaged beverage.

Calibration and adjustment at the push of a button

Data integration between laboratory and process instruments streamlines the documentation process, drives data consistency and eliminates transcription errors.The direct connection of process and laboratory analyzing systems with the evaluation software Davis 5 supports, semi-automates and simplifies the calibration and adjustment of Anton Paar’s process sensors with reference results from the lab.

Trace 15+ parameters from any location in the plant

Production runs can be monitored at any time and from any location in the plant. Davis 5 continuously collects and stores data, generating automated reports according to your requirements, e.g. standard deviation, operating times, line downtimes and quality data (Cp, Cpk and Quality Index, etc.). These reports can be exported as an XML or PDF file and sent to a smartphone, tablet or PC. Using an XML interface the data is seamlessly integrated with various Statistical Process Control solutions.

Global support and service from local specialists

Anton Paar’s global network provides local expertise and service by experienced support staff. Experts on call and service programs ensure peace of mind, guarantee the highest quality over an instrument’s lifespan, and reduce standby times.

Webinars

We offer you a great and constantly growing choice of live webinars and recordings on products, applications, and scientific topics.

View webinarsApplication Reports

Explore our database of application reports and find out how to overcome challenges in your field.

View application reports