Rotational Viscometer:

ViscoQC

- Single-point measurements on 3.5” color display

- Viscosity range from 1 mPa.s to 6,000,000 mPa.s

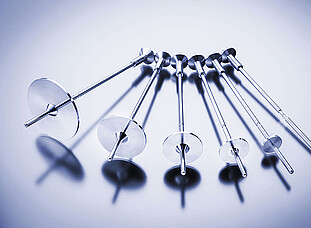

- 4 L spindles to measure low-viscosity samples (e.g. solvents, oils, and more)

Do you need an easy-to-use viscometer that provides convenient operation for the most reliable and traceable viscosity results in your day-to-day work? ViscoQC rotational viscometers ensure the quality of your substance – from liquid to semi-solid.

Eliminate the risk of measurement errors and free up your time and budget with the simplest spindle exchange mechanism, automatic spindle detection, automatic speed searching function for new formulations, and more.. Your existing SOPs can be easily converted if the same setup and settings are used.

It’s time to switch to an easier way. It’s time to switch to ViscoQC.

Key features

The easiest-to-use rotational viscometer – unpack and measure

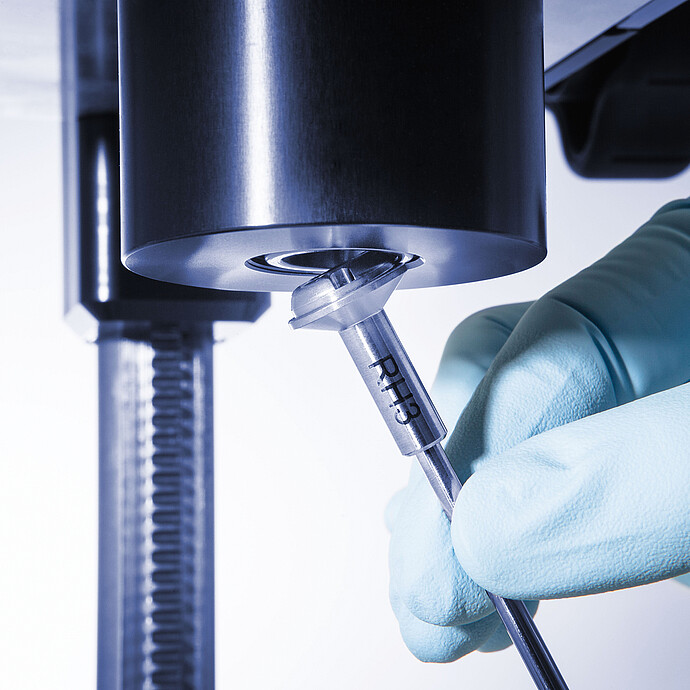

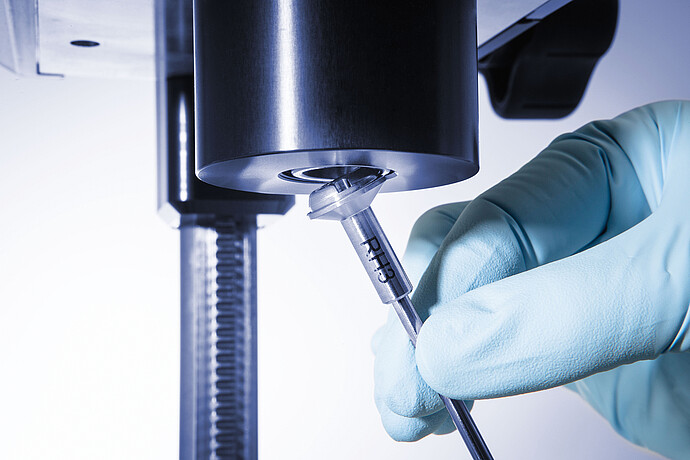

Setup takes less than two minutes: ViscoQC comes preassembled and includes an SOP booklet with first steps and straightforward user training. Our rotational viscometers guide you from startup through the entire measurement process via an intuitive user interface. Continue to use the SOP methods of your existing rotational viscometer: ViscoQC uses the same instrument setup and measuring settings to deliver the same results. Spindles with magnetic coupling for easy, fast, and safe spindle exchange come as standard.

Full traceability for reliable viscosity tests

Make your viscosity measurements error-proof and 100% traceable with our unique Toolmaster™ feature: spindles are automatically detected by the viscometer as soon as they’re attached. With ViscoQC 300, you can further restrict each method to a unique spindle identity. Furthermore, all connected accessories are detected and documented as well:

Built-in digital leveling automatically monitors and indicates the correct levelling status, which prevents faulty measurements and ensures remarkable, full-scale range accuracy of ± 1%. If you need to measure new formulations, ViscoQC automatically leads you to the right spindle/speed configuration using TruMode™.

Your future-proof rotational viscometer

You can upgrade your ViscoQC with accessories to cover any need:

- PTD 80 – For fast and accurate control of sample temperature (+15 °C to +80 °C)

- PTD 175 – High performance temperature control, suitable for standards like ASTM D2983/D8210/D5133/7110 and DIN 51398

- PTD 100 Cone-Plate – For small sample volumes (0.5 mL to 2 mL)

- ETD 300 – For high-temperature measurements of bitumen and hot melts, and for standards like ASTM D4402 and AASHTO T316

- Heli-Plus – For non-flowing substances like gels, pastes, and creams

You can add other software functionality to ViscoQC 300 with V-Curve, adding real-time graphs, analysis (e.g., yield point), programmability, and extended method functionality.

Be fully compliant within one day

ViscoQC is qualified and ready to use within a single day – compliant to 21 CFR Part 11, GMP, and GAMP 5. The V-Comply software for ViscoQC 300 delivers features like audit trail, electronic signature as well as the qualification documentation. The qualification is much more than a simple installation and basic IQ/OQ. An in-depth risk analysis, performance qualification, traceability matrix, and final qualification report enhance the value of the qualification package for the entire qualification process.

The most convenient way to generate and export QC data

Every ViscoQC includes the V-Collect PC data collection software. As ViscoQC 100 doesn’t store any data, results are directly exported or printed via the Brother QL-700 label printer after each test. ViscoQC 300 has memory space for up to 999 measurements with up to 10,000 sub-measurements on 150 MB. Additionally, it’s possible to print and export data as PDF, CSV, page printer (USB or network), or label printer. For automated data export, ViscoQC 300 can be integrated into your network via Laboratory Information Management System (LIMS) or FTP Server. Kickstart your paperless lab with AP Connect to connect your instruments, communicate measurement information, and ensure compliance.

Durable parts, maximum uptime

Since ViscoQC uses highly durable bearings and regularly performs an automatic bearing check (TruSine™), your uptime is maximized and ongoing service costs are reduced to a minimum. All of our spindles are made of superior stainless steel (AISI 316L), which increases spindle lifetime by protecting them from corrosion.

Technical specifications

| ViscoQC 100 | ViscoQC 300 | |||||

|---|---|---|---|---|---|---|

| L | R | H | L | R | H | |

| Viscosity test | Single-point | Multi-point | ||||

| Viscosity range [mPa.s or cP] (depends on measuring system) | 0.2* to 6 M | 1.6** to 40 M | 13.2*** to 320 M | 0.1* to 6 M | 1.3** to 40 M | 10.6*** to 320 M |

| Speed [rpm] | 0.1 rpm to 200 rpm 740 increments | 0.01 rpm to 250 rpm Speed list with 18 standard speeds Freely selectable speeds within the speed range | ||||

| Max. spring torque [mNm] | 0.0673 | 0.7187 | 5.7496 | 0.0673 | 0.7187 | 5.7496 |

| Accuracy | ±1.0 % full scale range | |||||

| Repeatability | ±0.2 % full scale range | |||||

| Heli-Plus compatibility | ✔ | |||||

| PTD 100 Cone-Plate compatibility | ✔ | |||||

| ETD 300 compatibility | ✔ | |||||

| Peltier temperature control | +15 °C to +80 °C 0 °C to + 100 °C | +15 °C to +80 °C 0 °C to + 100 °C | ||||

| Electrical temperature control | +25 °C to +300 °C (for SSA/DIN with ETD 300) | |||||

| Liquid temperature control/sensing | Ambient to +100 °C (control of L/RH spindles with optional thermostat bath) | |||||

| Temperature sensing | -60 °C to +300 °C (temperature sensing with optional Pt100) | |||||

| Intuitive user interface | 3.5" color LCD display | 7" color touchscreen display; Options: keyboard, mouse, 2D bar code reader | ||||

| Languages | EN, DE, ES, FR, CN, JA, KO, IT, RU, PT | EN, DE, ES, FR, IT, PT, JA, KO, RU, ZH-CN, ZH-TW, PO, CZE | ||||

| Built-in digital leveling | ✔ | |||||

| Easiest spindle exchange (magnetic coupling) | ✔ | |||||

| Automatic spindle recognition (Toolmaster™) | ✔ | |||||

| Automatic measuring range calculation | ✔ | |||||

| Automatic speed searching function (TruMode™) | ✔ | |||||

| Spindle correction by user | ✔ | |||||

| Users, user groups | None | ✔ Customizable | ||||

* With optional PTD 100 Cone-Plate, with L1 spindle 15 mPa.s

** With optional PTD 100 Cone-Plate, with RH1 spindle 100 mPa.s

*** With optional PTD 100 Cone-Plate, with RH1 spindle 800 mPa.s

M = million

DIN = Concentric cylinders, double-gap

SSA = Small sample adapter (SC4-xx)

UL = Ultra-low viscosity adapter

Standards

AASHTO

ASTM

BS

Chinese Pharmacopoeia (ChP)

DIN

EN

ISO

Japanese Pharmacopoeia (JP)

Pharmacopoeia Europe (Ph. Eur.)

TAPPI

U.S. Pharmacopoeia (USP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Adhesives | Measurement of Hot Melt Adhesives According to ASTM D3236 Application Reports

-

Adhesives | ViscoQC Quality Control of Adhesives Application Reports

-

Beverages | ViscoQC Quality Control of Fruit Juice Application Reports

-

Chemicals | Rotational Viscosity Testing in Battery Cell Manufacturing Application Reports

-

Chemicals | Rotational Viscosity Testing of Isocyanates with ViscoQC Application Reports

-

Coatings, Paints | ViscoQC Quality Control of Coatings and Paints Application Reports

-

Cosmetics | Rotational Viscosity Testing of Make-up (Remover) with ViscoQC Application Reports

-

Cosmetics, Pharma | Rotational Viscosity Testing of Hand Sanitizer with Visco Application Reports

-

Detergents | ViscoQC Quality Control of Dishwashing Detergents Application Reports

-

Food | Rotational Viscosity Testing of Chocolate with ViscoQC Application Reports

-

Food | Rotational Viscosity Testing of Dairy Products with ViscoQC Application Reports

-

Food | Rotational Viscosity Testing of Porridge with ViscoQC Application Reports

-

Food | Rotational Viscosity Testing of Sauces and Dressings with ViscoQC Application Reports

Similar products

ViscoQC FAQ

A. General

B. Cleaning

C. Maintenance

D. ViscoQC 300 and its software packages

E. Contact

Consumables, Accessories & Software

Consumables, Accessories & Software

Accessories & Software

Accessories & Software

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

MOUNTING LINK SET

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Vapor protection for PTD 80

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

TOUCHSCREEN STYLUS

ViscoQC 300 L | 300 R | 300 H

Flat bath cover for PURA 10

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

COOLING COIL FOR PURA 10

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

JULABO PURA 10 WATERBATH 20...100 °C +/-0.15 °C, 230V/50-60Hz

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

LABELS 90 x 29 mm, 1 x 400 pcs. FOR BROTHER Label Printer

ViscoQC 100 L | 100 R | 100 H

Pt100 Clip

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Marking Tool CC12/Dm18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Display Protection Foil ViscoQC 300

ViscoQC 300 L | 300 R | 300 H

Spindle L5

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

ANGULAR SCREWDRIVER TORX T10

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

ANGULAR SCREWDRIVER TORX T20

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

O-RING 22x3 VMQ 70 SILICONE (RED-BROWN)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- O-ring sitting on the bottom plug of cups of the following DIN/SSA/UL systems.

- Recommended for low- and high-temperature range, especially when working with PTD 175 Peltier temperature device.

VISCOSITY STANDARD APCL68 CCS (500 mL)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 19,584 mPa.s (-15 °C) up to 11,417 mPa.s (-10 °C)

VISCOSITY STANDARD APCL60 CCS (500 mL)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 21,961 mPa.s (-18 °C) up to 5,731 mPa.s (-5 °C)

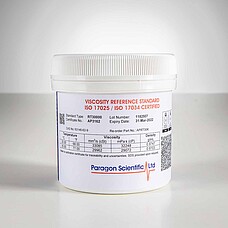

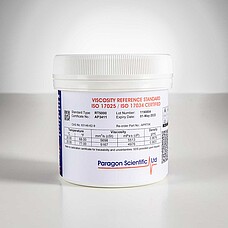

SILICONE VISCOSITY STANDARD AP RT30k 600 ml - 33 / 30 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- 33 Pa·s / 30 Pa·s at 20 °C / 25 °C

- Recommended for ViscoQC x00 - H

SILICONE VISCOSITY STANDARD AP RT5k 600 ml - 5.6 / 5.0 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- 5.6 Pa·s / 5.0 Pa·s at 20 °C / 25 °C

- Recommended for ViscoQC x00 - R

SILICONE VISCOSITY STANDARD AP RT500 600 ml - 554 / 501 mPa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- "554 mPa·s / 501 mPa·s at 20 °C / 25 °C

- Recommended for ViscoQC x00 - L and ViscoQC x00 - R"

SILICONE VISCOSITY STANDARD AP RT10 600 ml - 11 / 10 mPa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- 11 mPa·s / 10 mPa·s at 20 °C / 25 °C

- Recommended for ViscoQC x00 - L

VISCOSITY STANDARD ANTON PAAR N26 (C) 100 ml - 50 / 21 / 4.2 mPa.s

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N7.5 (M) 100 ml - 10 / 5.4 / 1.6 mPa.s

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR S3 (L) 100 ml - 3.7 / 2.3 / 0.9 mPa.s

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for DIN/SSA/UL spindles

VISCOSITY STANDARD ANTON PAAR N415 (H) 100 ml - 1100 / 330 / 32 mPa.sc

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for DIN/SSA/UL spindles

LABELS 89 x 28 mm, 2 x 130 pcs. FOR DYMO LabelWriter

ViscoQC 100 L | 100 R | 100 H

For Dymo LabelWriter (ViscoQC 100 only)

LABELS 89 x 36 mm, 2 x 260 pcs. FOR DYMO LabelWriter

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

For Dymo LabelWriter (ViscoQC 100, ViscoQC 300)

SILICONE VISCOSITY STANDARD AP RT50 600 ml - 55 / 50 mPa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

55 mPa·s / 50 mPa·s at 20 °C / 25 °C

SILICONE VISCOSITY STANDARD AP RT100 600 ml - 111 / 100 mPa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

111 mPa·s / 100 mPa·s at 20 °C / 25 °C

SILICONE VISCOSITY ETALON AP RT1k 600 ml - 1.1 / 1.0 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

1.1 Pa·s / 1.0 Pa·s at 20 °C / 25 °C

SILICONE VISCOSITY STANDARD AP RT12k 600 ml - 14 / 13 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

14 Pa·s / 13 Pa·s at 20 °C / 25 °C

SILICONE VISCOSITY STANDARD AP RT60k 600 ml - 66 / 60 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

66 Pa·s / 60 Pa·s at 20 °C / 25 °C

SILICONE VISCOSITY STANDARD AP RT100k 600 ml - 111 / 100 Pa.s at 20 / 25 °C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

111 Pa·s / 100 Pa·s at 20 °C / 25 °C

FOAM PACKING MATERIAL ViscoQC

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

VITON O-RING FOR DIN/SC4 SYSTEMS

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

O-ring sitting on the bottom plug of cups of the following DIN/SSA systems.

HOLDER DISPOSABLE MEASURING CUP D18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

GLASS ROD

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

10 pcs. of glass rods for Gel Time Kit.

DISPOSABLE MEASURING CUP D22 1 pack = 100 pcs. (blank aluminium)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

For measuring system 4B2 insulated and L1D22.

VISCOSITY STANDARD APCL16 CCS (500 mL)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 10 459 mPa.s (-40°C) up to 1 014 mPa.s (-18°C)

VISCOSITY STANDARD APCL20 CCS (500 mL)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Low-temperature viscosity standard

- Viscosity values from 21,337 mPa.s (-40 °C) up to 862.4 mPa.s (-10 °C)

VISCOSITY STANDARD APCL25 CCS (500 mL)

ViscoQC 100 L | 100 R | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 19,907 mPa.s (-35 °C) up to 1,371 mPa.s (-10 °C)

VISCOSITY STANDARD APCL28 CCS (500 mL)

ViscoQC 100 L | 100 R | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 16,682 mPa.s (-30 °C) up to 2,022 mPa.s (-10 °C)

VISCOSITY STANDARD APCL38 CCS (500 mL)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Low-temperature viscosity standard.

- Viscosity values from 20,950 mPa.s (-25 °C) up to 2,670 mPa.s (-5 °C)

High-Temperature Viscometer Accessory:

ETD 300

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Temperature control from +25 °C to +300 °C

- Applicable for ViscoQC 100 and 300

- Full control via ViscoQC display

- For measurement of bitumen, hot melts, polymers, waxes

- Complies with ASTM D4402, D3236, AASHTO T316, EN 13302, and more

MEASURING BOB CP40

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

LABEL PRINTER USB BROTHER Label Printer QL-700

ViscoQC 100 L | 100 R | 100 H

MEASURING BOB CP41

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Temperature Control Solutions for ViscoQC:

Temperature Device PTD 175

ViscoQC 300 L | 300 R | 300 H

- For ViscoQC 300; viscometer and temperature device from a single source

- Air cooling saves tempering time and reduces maintenance costs

- From low-temperature engine oil to high-temperature asphalt binder tests

- Wide-range Peltier device: -45 °C to +175 °C (±0.1 °C)

MEASURING BOB CP52

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB CP51

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB CP42

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING CUP PTD 100 Cone-Plate

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring Cup C-8R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

CARRYING CASE ViscoQC

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring System SC4-15/7R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING SYSTEM DG26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

Cone-Plate Measuring System with Integrated Peltier Temperature Device:

PTD 100 Cone-Plate

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- For small sample volumes from 0.5 mL to 2 mL

- Upgrades ViscoQC 100 and 300 to a cone-plate viscometer

- Two in one: Cone-plate and Peltier temperature device combined

- Automated gap setting process

- Magnetic coupling, Toolmaster™ feature, and temperature probe as standard

MEASURING SYSTEM CC26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING BOB B-SC4-14

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING SYSTEM CC18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING BOB B-SC4-15

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING SYSTEM CC12

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING BOB B-SC4-16

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE GUARD R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for ViscoQC x00 - R

Measuring Cup C-6R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE GUARD L

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Recommended for ViscoQC x00 - L

Measuring Cup C-7R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

PT100 TEMPERATURE SENSOR

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Comes with a metal clip (mounting clamp) for fixing the Pt100 sensor on the rim of open sample vessels or on the L/R spindle guard.

Measuring System SC4-14/6R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

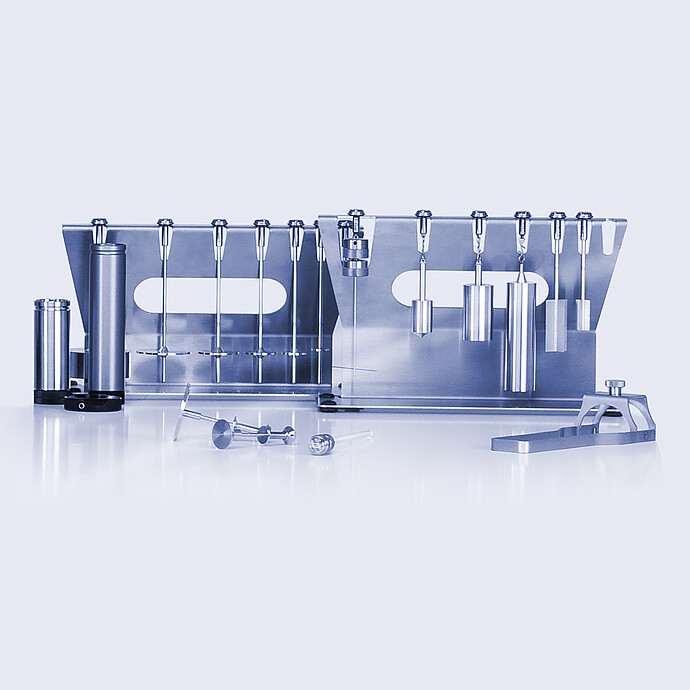

SPINDLESET RH

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring System SC4-16/8R

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLESET L

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Temperature Control Solutions for ViscoQC:

Temperature Device PTD 80

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- For ViscoQC 100/300; viscometers and temperature device from a single source

- Air cooling ensures small footprint, and reduces maintenance costs

- Exact sample temperature control of, e.g. chocolate, adhesive

- For routine QC applications from +15 °C to +80 °C (±0.1 °C)

SPINDLE RH1

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Motorized accessory for ViscoQC 100/300:

Heli-Plus

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Convenient operation thanks to motorized stand instead of manual height adjustment

- Measure paste-like materials (e.g. mayonnaise) with helical T-bar spindle movement

- Simplest spindle exchange saves up to 15 seconds per measurement

SPINDLE RACK

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE SET T-Bar

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

DIN ADAPTER

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Required for measurement with a concentric cylinder (CC), double-gap (DG), ultra-low viscosity adapter (UL), or SSA (SC4) measuring system if not using a Peltier temp. device.

MEASURING CUP C-CC26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

KEYBOARD USA USB

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING CUP LOCK

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

KEYBOARD GERMAN USB

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

PROTECTING COVER FOR KEYBOARD

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring System DG26/SS

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

USB CABLE

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

JULABO CORIO C-BT5 BATH THERMOSTAT 20...100 °C +/-0.03 °C, 208-230V/50-60Hz

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires stand for bath thermostat (P/N 194946) and stainless bath cover (P/N 194765) to be mounted on ViscoQC and to operate 600 mL beakers from ambient to +100 °C. 208 V to 230 V / 50 Hz to 60 Hz

Accessory for ViscoQC 100/300:

Flexible Cup Holder

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

- Ensures your sample is always centered in the right place

- To easily center ½ pint, pint, quart containers, or 600 mL beakers

- Easily mounted on instrument stand

- Guarantees reproducible results

STAINLESS BATH COVER FOR 600 ml BEAKER ACCESSORY JULABO CORIO C-BT5 (191891)

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

For Julabo bath thermostat to operate 600 mL beakers

SPINDLE T-E

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

STAND FOR BATH THERMOSTAT CORIO C-BT5

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

To mount Julabo bath thermostat on ViscoQC

CLAMP FOR T-Bar SPINDLE

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

JULABO CORIO C-BT5 BATH THERMOSTAT 20ºC_100°C +/-0.03°C, 100-115V/50-60Hz

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires stand for bath thermostat (P/N 194946) and stainless bath cover (P/N 194765) to be mounted on ViscoQC and to operate 600 mL beakers from ambient to +100 °C. 100 V to 115 V / 50 Hz to 60 Hz

SPINDLE T-D

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLESET VANES

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Includes vane spindles V71 to V73.

SPINDLE T-B

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE V75

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Has only full immersion. For very low sample volume.

SPINDLE T-A

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring System SC4-21

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

Measuring System SC4-18

ViscoQC 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

SPINDLE T-C

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring System SC4-27

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

ETHERNET CABLE FOR PC CONNECTION CAT5E, RJ45G-RJ45G, SFTP, 2 m, CROSSED

ViscoQC 300 L | 300 R | 300 H

Only for ViscoQC 300. Cable for LIMS Bridge connection to PC for transferring measurement data.

SPINDLE T-F

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

COVER DIN SPINDLES

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Made of PEEK to cover cups of DIN/SSA systems.

BARCODE SCANNER 2D WITH USB CABLE

ViscoQC 300 L | 300 R | 300 H

Only for ViscoQC 300

Measuring Systems for ViscoQC:

Spindle

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

DISPOSABLE MEASURING SYSTEM CC12/D18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

Temperature Control Solutions for ViscoQC:

Temperature Device

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE V74

ViscoQC 100 L | 100 R | 300 L | 300 R | 300 H

Has only full immersion. For very low sample volume.

EXTERNAL POWER SUPPLY

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE L1

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

COOLING COIL FOR BATH THERMOSTAT

ViscoQC 100 R | 100 H | 300 L | 300 R | 300 H

- For operating the Julabo CORIO™ C-BT5 Bath

- Thermostat close to ambient temperature

SPINDLE L2

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

ANGULAR SCREWDRIVER TORX T30

ViscoQC 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE L3

ViscoQC 100 L | 100 R | 100 H | 300 R | 300 H

SPINDLE L4

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH2

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH3

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH4

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH5

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH6

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

SPINDLE RH7

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

PACKING SPINDLESET ViscoQC

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB B-CC12

ViscoQC 100 L | 100 R | 300 L | 300 R | 300 H

MEASURING CUP C-CC12

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB B-CC18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING CUP C-CC18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB B-CC26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING BOB B-DG26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING CUP C-DG26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING CUP C-DG26/SS

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring cup C-CC18/SS

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring bob B-SC4-18

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring bob B-SC4-21

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Measuring bob B-SC4-27

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

MEASURING SYSTEM SC4-28

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING SYSTEM SC4-29

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING SYSTEM SC4-31

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING SYSTEM SC4-34

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter or Peltier temp. device to be mounted on ViscoQC

MEASURING SYSTEM UL26

ViscoQC 100 L | 100 R | 100 H | 300 L | 300 R | 300 H

Requires DIN adapter to be mounted on ViscoQC or PTD 175 Peltier temperature device for ViscoQC 300 only

Software Solutions for ViscoQC:

Software V-Curve

ViscoQC 300 L | 300 R | 300 H

- Upgrade your stand-alone ViscoQC 300

- Follow your measurement data live

- Programmable with up to 50 steps for more sophisticated tests

- For easy analysis of test data, e.g. yield stress, gel time, pot life

Lab Execution Software:

AP Connect Start

ViscoQC 300 L | 300 R | 300 H

- Now: 100 % discount at checkout!

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

Lab Execution Software:

AP Connect Standard subscription license

ViscoQC 300 L | 300 R | 300 H

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Standard one-time license

ViscoQC 300 L | 300 R | 300 H

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Pharma subscription license

ViscoQC 300 L | 300 R | 300 H

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Pharma one-time license

ViscoQC 300 L | 300 R | 300 H

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips