Temperature Control:

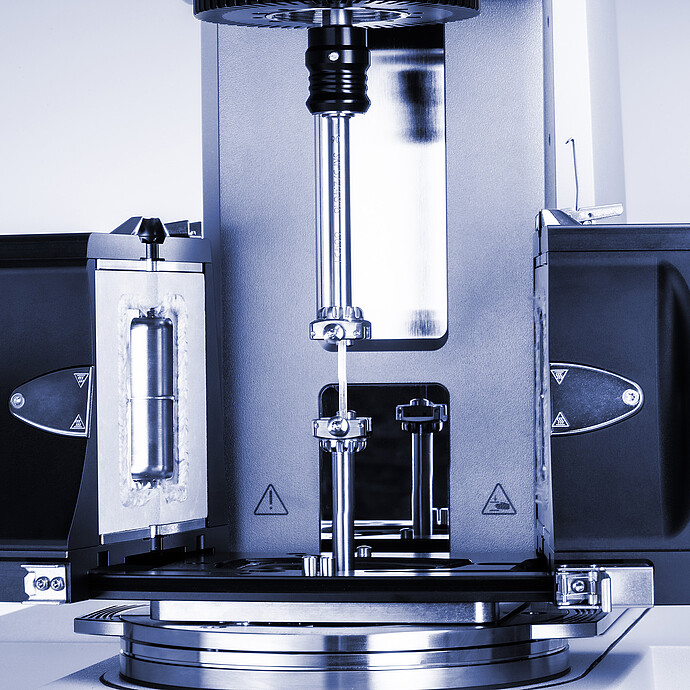

Convection Temperature Devices (-160 °C to +1000 °C)

- For temperature-controlled rheological and DMA measurements on melts, solids, films, and fibers from -160 °C to 1000 °C

- Homogeneous temperature distribution for accurate & stable results

- For MCR measuring systems: parallel-plate, cone-plate, DMA in torsion or extension, controlled relative humidity, and more

Perfect temperature control for measurements on melts and solids (DMA) and extensional rheology on films and fibers – the convection temperature devices for the MCR rheometer series make it happen. Due to their symmetric design, they guarantee an absolutely homogeneous temperature distribution and thus accurate and stable temperature control in all measuring systems, from parallel plates to solid bar fixtures, for optimal results when measuring polymer melts, glass melts, salt melts, metal melts, and solids. With their innovative design and comprehensive range of accessories, the convection temperature devices are a must for experienced rheologists.

Key features

Control the greatest influence of all

The convection temperature devices allow for controlling the greatest rheological influence of all: temperature. Benefit from an enormous temperature range to meet your specific sample requirements. At the same time the design gives you the possibility to use almost every measuring system from the extensive MCR accessory portfolio, from parallel-plate systems (including disposable systems) to dynamic mechanical analysis in torsion or extension. Furthermore, a controlled relative humidity can also be applied to the sample in combination with temperature. Rely on the high-precision temperature control required for truly accurate results for all kinds of rheological tests.

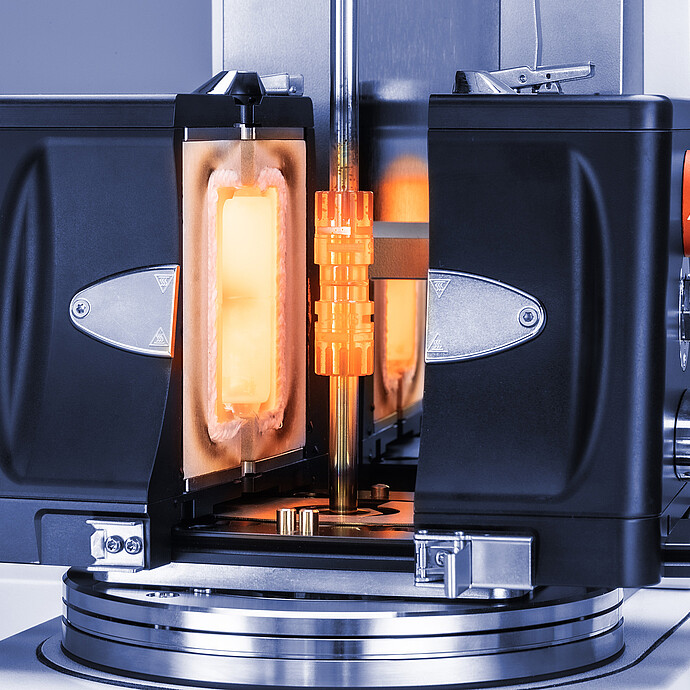

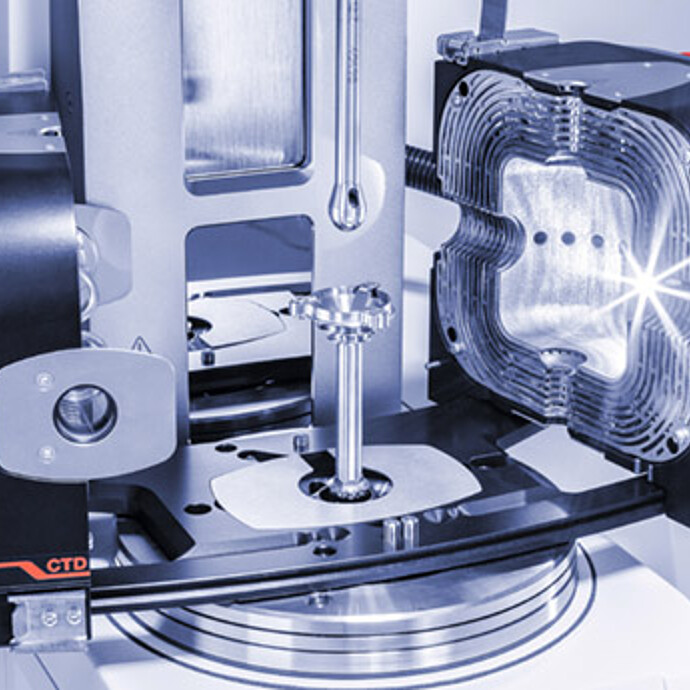

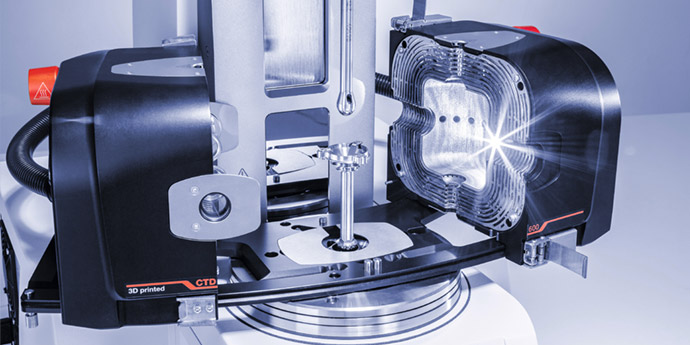

Count on the most innovative production techniques

State-of-the-art production techniques such as 3D metal printing bring temperature control to the next level. The unique design of the inner shells of the CTD 600 MDR convection temperature device, which are manufactured as one piece each, results in an absolutely homogeneous temperature distribution within the oven. With CTD 600 MDR, temperature gradients are a thing of the past. Additionally, only low gas flow rates are needed, minimizing unwanted effects on measurements due to air vortexes or drying samples.

Extensive MCR accessory portfolio

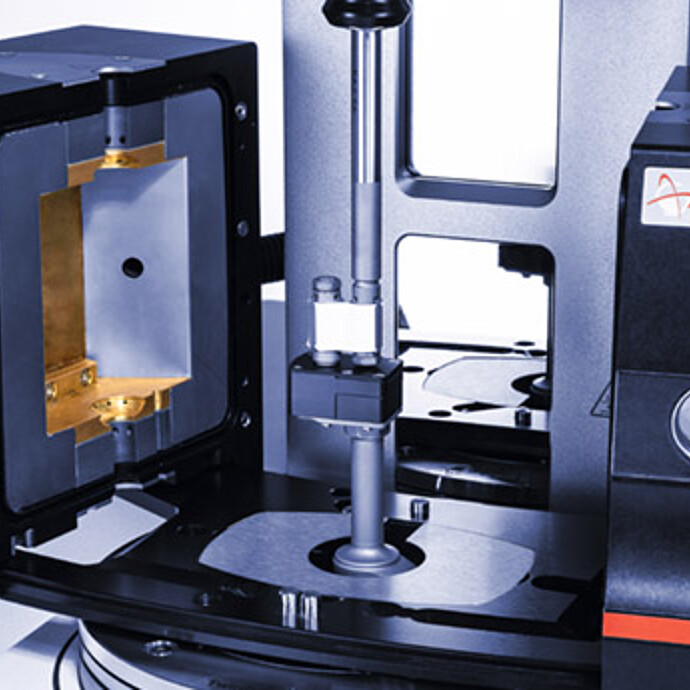

A wide range of applications require flexible temperatures, measuring systems, and testing solutions. In addition to standard measuring systems, solutions made of Inconel, graphite, or other temperature- and corrosion-resistant materials allow characterization of a broad variety of samples and even high-temperature materials (e.g., metals, salts, glass). Beyond rheological measurements and dynamic mechanical analysis, convection temperature devices enable powder rheology and liquid density measurements up to 1000 °C. Anton Paar’s CTD 1000 MDR can be combined with a lower linear drive to perform dynamic mechanical analysis in tension, compression, and bending up to 1000 °C. For applications in an oxygen-free environment, Anton Paar offers an Argon glovebox proofed configuration based on the MCR 702e Space MultiDrive.

Low temperature options to match every application are also available.

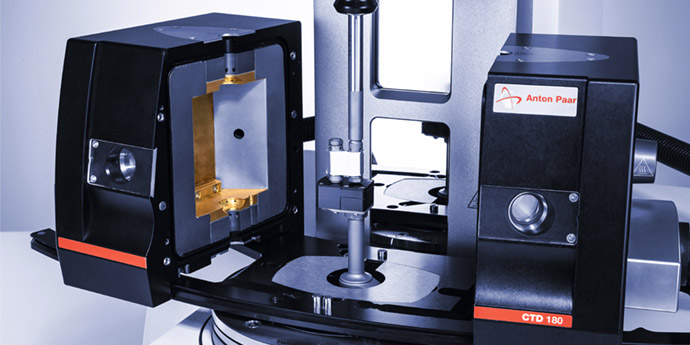

Enjoy the comfortable setup and ease of use

Whichever choices you make, all temperature devices are swiftly and easily integrated and exchanged, and your rheometer reliably adapts to each new setup and temperature requirement. The following MCR features make sure of this: Toolmaster™ automatically recognizes and configures all connected devices, TruGap™ controls and adjusts the rheometer’s actual measuring gap. T-Ready™ cuts short unnecessary waiting times by immediately detecting temperature equilibration. The integrated non-reflecting interior illumination of the CTD 600 MDR temperature device ensures a perfect view of your sample during the measurement.

Rely on full safety even at high temperatures

All the outside surfaces of Anton Paar’s convection temperature devices for the MCR series are touch-proof up to the highest temperatures. The exhausts are designed with cooling mechanisms to ensure safe and convenient use at any time, at any temperature. When closing the ovens, an integrated mechanism prevents the shells from touching the measuring system, avoiding damage to the device.

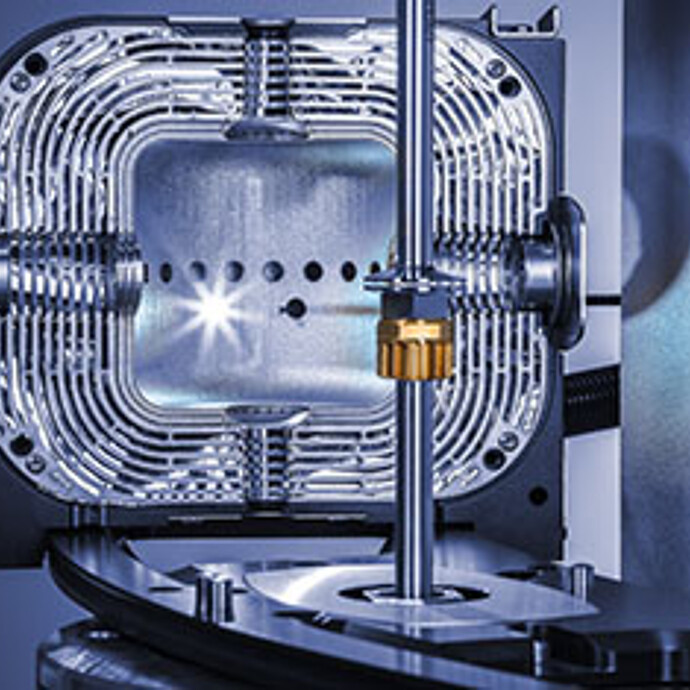

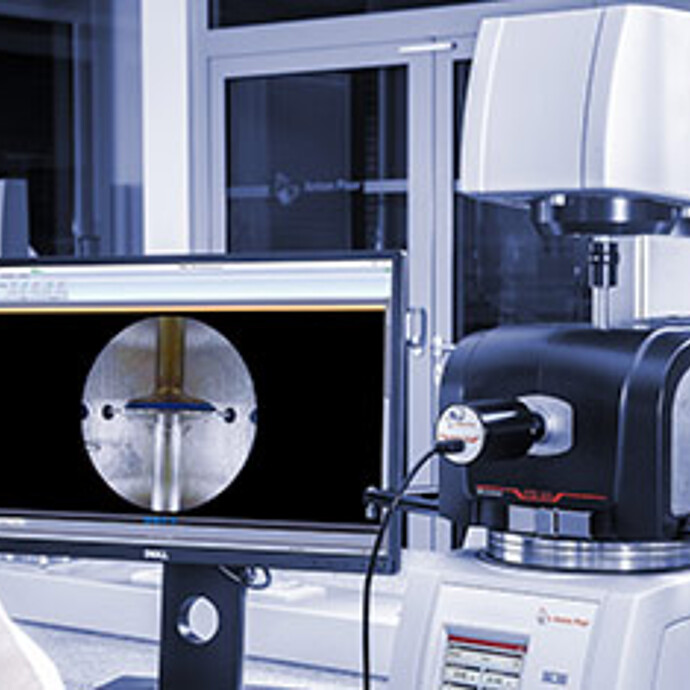

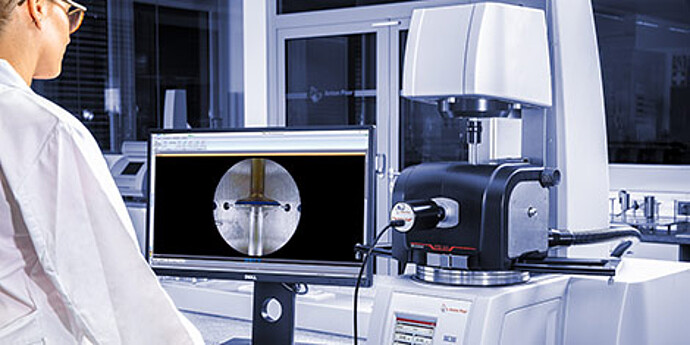

Gain real-time insights into your sample during the measurement

The combination of the integrated interior illumination with the high-quality optical system of the digital eye camera ensures sharp and uniformly illuminated real-time pictures and videos of your sample over the complete temperature range. This allows for detailed investigations of different measurement effects, such as edge fracture, sagging, optically visible phase transitions, degradation, and gap emptying. Furthermore, this data can add valuable information to the analysis and validate measurement results. The real-time camera pictures and videos are displayed in the media explorer of the rheometer’s RheoCompass™ software and can be directly added to a diagram and assigned to the measuring points at which they were recorded. The digital eye camera can be installed on CTD in less than one minute.

Technical specifications

| Chamber | Temperature range | Temperature control | Max. heating rate | Max. cooling rate | Typical materials | Measuring systems¹ | Accessories |

| CTD 180 | -20 °C to 180 °C | Peltier convection | 18 °C/min | 10 °C/min | food, coatings, paints, cosmetics, pharmaceuticals, detergents, solvents, adhesives, sealants, plastisols, hotmelts, petrochemicals, asphalt, bitumen, epoxy resins, polymer solutions | PP, PP disposable, CP, CC, SRF, UXF, SCF, SER, tribology, CTL, TPB, powder shear cell | Optional:

|

| CTD 450 TDR | -150 °C to 450 °C | Electrical convection | 50 °C/min | 35 °C/min | polymer melts, reinforced materials, films and fibers, epoxy resins, aluminum, metals and alloys, low-temperature glasses | PP, PP disposable, CP, CC, SRF, UXF, SCF, SER, CPP, tribology | Optional:

|

| CTD 600 MDR | -160 °C to 600 °C | Electrical convection | 35 °C/min | 30 °C/min | polymer melts, reinforced materials, films and fibers, epoxy resins, aluminum, metals and alloys, low-temperature glasses | PP, PP disposable, CP, CC, SRF, UXF, SCF, SER, CPP, tribology, CTL, TPB, powder shear cell | Included:

|

| CTD 1000 MDR | -150 °C to +1000 °C | Electrical convection | 60 °C/min | 30 °C/min | Metals and alloys (e.g., aluminum), low-temperature glass, salts | PP, CC, SRF, TPB | Optional: |

[1] Ask for customized measuring systems

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Determining the Glass Transition Temperature of PEEK with SCF Application Reports

-

Determining the Viscosity of Molten Salts Application Reports

-

Dynamic Mechanical Analysis of Glass Using Multiwave Tests Application Reports

-

Mechanical Thermal Behavior of PVC Based Strip Doors Application Reports

-

Practically relevant rheological analysis of polymers using a modern rheometer Application Reports

-

Relaxation time(s) and the relaxation time spectrum H(λ) of a polypropylene melt Application Reports

-

Rheological Investigations of Sensible Thermal Energy Storage Materials Application Reports

-

Brochure | Mining Industry Brochures

-

Datasheet | High-Temperature Rheology Brochures

-

Instruments - MCRxx2 Evolution series Brochures

Compatible instruments

Similar products

Consumables

Consumables

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

DISPOSABLE MEASURING CUP C-CC39/D/AL 1 pack = 100 pcs

SILICON MOLD FOR ASPHALT BINDER (PP25) ACCORDING AASHTO T315

HOSE 3x5 SILICONE

HOSE 4X6 NYLON

DISPOSABLE MEASURING CUP C-CC27/D/AL 1 pack = 100 uds.

DISPOSABLE DISHES 56 mm 1 PACK = 100 PIECES

ANTIFREEZE FOR WATER COOLING SYSTEMS AND THERMOSTATS

- Suitable for aluminum

- Silicate free

- Free of amines, nitrites and phosphates

Recommended for the cooling system of Multiwave 7000. 1 btl = 1.5 l