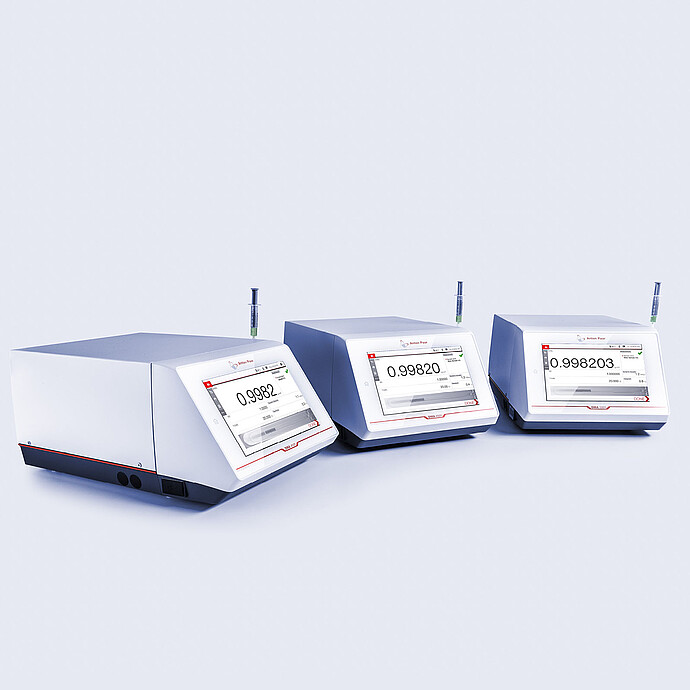

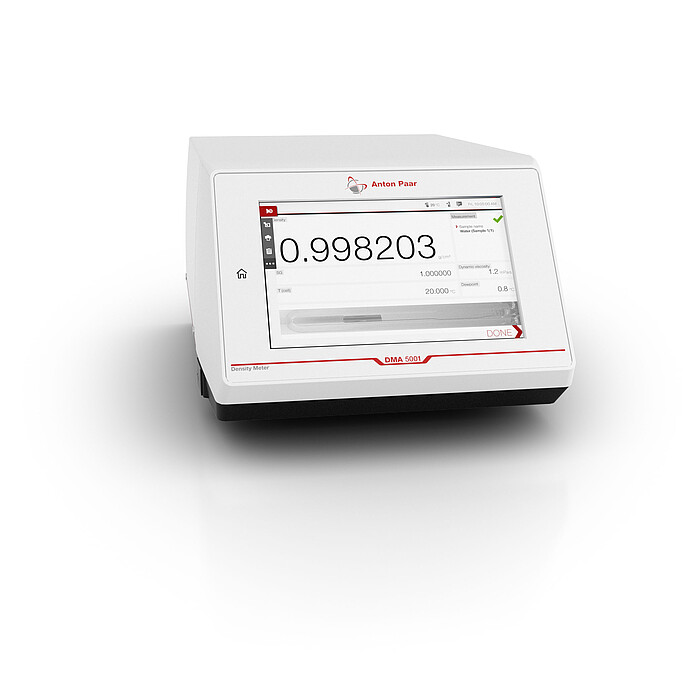

Benchtop Density Meter:

DMA

- 4-digit measurements in 20 seconds

- Ultra-fast measurement mode maximizes throughput

- Best-in-class filling control provides reliable results

- 200+ conversion tables for quicker results

We’ve incorporated over five decades of experience developing market-leading benchtop density meters into our new generation of density meters. With best-in-class U-tube technology based on our patented Pulsed Excitation Method, our Next-Level Density Meters are the fastest, most intelligent benchtop density meters we’ve made to date.

20-second (4-digit) results give you high throughput. Compliance with a range of standards gives you peace of mind. There’s storage space for up to 10,000 measurements. And up to 6-digit accuracy gives you results you can rely on.

Now that’s taking it to the next level.

Key features

Fast and accurate benchtop density meters

- Get market-leading precision, repeatability, and reproducibility with our patented Pulsed Excitation Method

- Maximize throughput with an ultra-fast measurement mode

- Define limits for different samples and make pass/fail QC decisions right away

- 200+ pre-installed conversion tables show concentration values immediately

- Achieve excellent results for highly viscous samples with the best viscosity correction on the market

- Get reliable measurement results for high- and low-density samples as well as inhomogeneous, sedimenting, or particle-containing ones

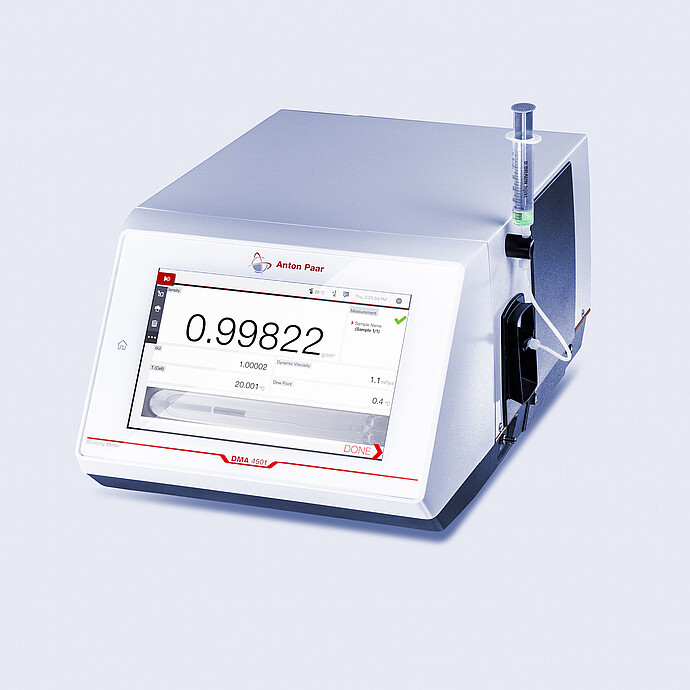

High-tech features simplify your lab

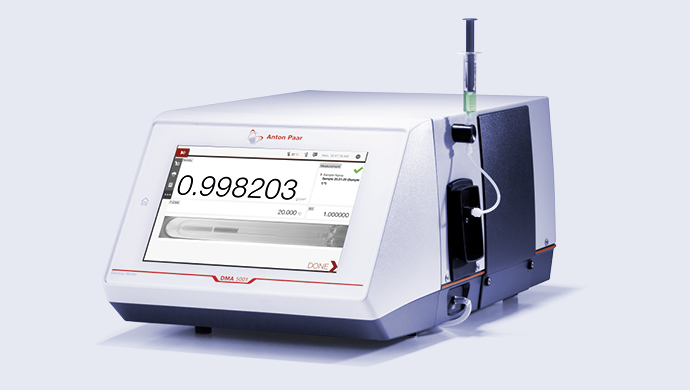

- Know your samples are filled correctly with FillingCheck™, which even detects microbubbles, and U-View™, which shows a zoomable image of the measuring cell

- Benefit from an automatic compensation of the U-tube’s aging effects and minimized drift over the lifetime of the instrument

- Use 30+ guided user workflows and five industry-specific profiles with predefined quantities and scales

- Streamline your data management with AP Connect

Guaranteed compliance gives you peace of mind

- Comply with ASTM D4052, D5002, D1250, ISO 12185 petroleum standards, and all relevant pharmacopeias

- Satisfy all major data integrity and traceability standards (e.g., 21 CFR Part 11)

- Ensure your results are traceable to the International System of Units (SI) with ISO 17025 calibration from our accredited lab

- Use our ISO 17034-certified reference material for density to ensure your instrument is perfectly calibrated

Modularity lets you conduct multiparameter analysis

- Connect your benchtop density meter to a range of Anton Paar measuring modules to forge a multiparameter system

- Measure all relevant QC parameters from the same sample under the same conditions

- Measure more than eight parameters at once

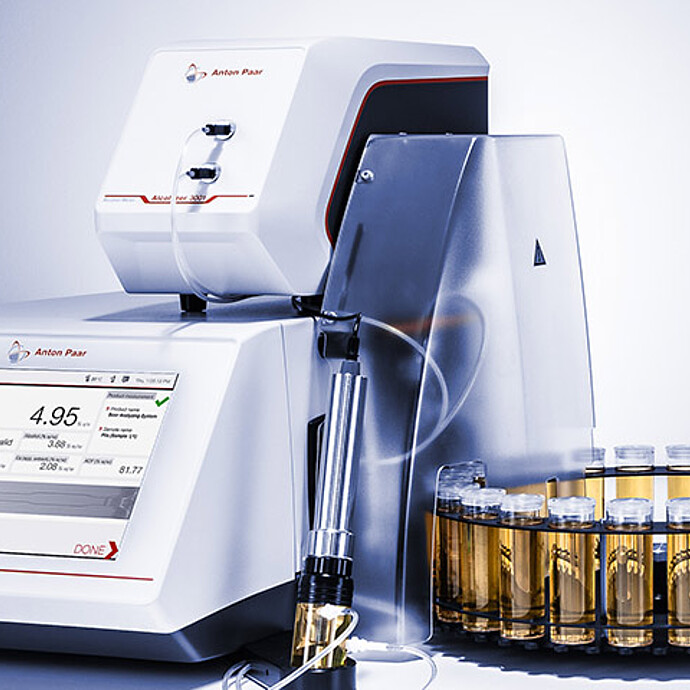

Automated processes for higher throughput

- Automate your filling, measuring, and cleaning process by choosing from seven different sample changers (optional)

- Ensure accurate results without operator influence

- Reduce contact with dangerous substances during filling with automated sample changers

Technical specifications

| DMA 4101 | DMA 4501 | DMA 5001 | |

| Measuring range | |||

| Density | 0 g/cm³ to 3 g/cm³ | ||

| Temperature | 0 °C to 100 °C (32 °F to 212 °F) | ||

| Pressure | Up to 10 bar (145 psi) absolute pressure | ||

| Accuracy | |||

| Density | 0.0001 g/cm³ | 0.00005 g/cm³ (full range) 0.00001 g/cm³ (0 g/cm³ to 1 g/cm³, 15 °C to 20 °C) | 0.000005 g/cm³ |

| Temperature | 0.03 °C (0.05 °F) | 0.02 °C (0.04 °F) (full range) 0.01 °C (0.02 °F) (15 °C to 20 °C) | 0.01 °C (0.02 °F) |

| Repeatability | |||

| Density | 0.00001 g/cm³ | 0.000005 g/cm³ | 0.000001 g/cm³ |

| Temperature | 0.02 °C (0.04 °F) | 0.01 °C (0.02 °F) | 0.001 °C (0.002 °F) |

| Reproducibility | |||

| Density | 0.00005 g/cm³ | 0.00002 g/cm³ | 0.000005 g/cm³ |

| Digital resolution | |||

| Density | 0.0001 g/cm³ | 0.00001 g/cm³ | 0.000001 g/cm³ |

| Features | |||

| Power features | U-View™, FillingCheck™, ThermoBalance™, full-range viscosity correction | ||

| Special functions | QM compliance, temperature scan, built-in ambient pressure sensor, condition monitoring adjustment at high viscosity (only DMA 5001 ) | ||

| Automation | Automatic sample changers | ||

| Modularity | pH, alcohol, CO2, O2, color, turbidity, refractive index | ||

| Optional accessories | Aerosol adapter, heating attachment | ||

| Technical data | |||

| Typical measuring time/sample | 20 s | 30 s | 40 s |

| Minimum sample volume | Approx. 1 mL | ||

| Wetted materials | PTFE, borosilicate glass | ||

| Dimensions (L x W x H) | 526 mm x 347 mm x 230 mm (20.7 in x 13.7 in x 9 in) | ||

| Weight | 22.04 kg (48.6 lbs) | ||

| Power supply | AC 100 to 240 V, 50/60 Hz, fluctuation ±10 %, 190 VA | ||

| Display | 10.1" TFT WXGA (1280 x 800 px); PCAP touchscreen | ||

| Controls | Touchscreen, optional keyboard, mouse, and barcode reader | ||

| Communication interfaces | 5 x USB, Ethernet, CAN, RS232 | ||

| Internal storage | More than 10,000 measuring values with camera images | ||

Standards

2020 Chinese Pharmacopoeia

ABNT

AOAC

ASBC

ASTM

CPTC

DIN

EBC

European Union

GB

HG

HM Revenue & Customs

IP

ISO

JIS

JJF

Japanese Pharmacopoeia (JP)

OIML

OIV

Pharmacopoeia Europe (Ph. Eur.)

QB

RANP

SH

TTB

U.S. Pharmacopoeia (USP)

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Alcohol Measurement Using Anton Paar Density Meters Application Reports

-

Assessment of Quality Control Measurements for Disinfectants and Hand Sanitizers Application Reports

-

Compensate your density results Application Reports

-

Density Measurement of Infusion Solutions in Hospital Pharmacies Application Reports

-

Density measurement gets the battery industry going Application Reports

-

Density measurement of biodiesel Application Reports

-

Density measurement of cleaning agents and disinfectants Application Reports

-

Density measurement of gases with DMA 4101/4501/5001 Application Reports

-

Density measurement of lithium-containing electrolytes Application Reports

-

Density measurement to ensure the quality of aqueous urea solutions Application Reports

-

Determination of Alcohol and Extract Content in Spirits and Liqueurs Application Reports

-

Determining filling volumes based on density measurement Application Reports

-

E-Book - Field Guide to Battery Materials Characterization – Revised and Updated Application Reports

-

Efficiency Meets Sustainability – Biodiesel Measurements Made Easy Application Reports

-

Food | Dairy Products | Density measurement of milk and dairy products Application Reports

-

From Measuring Result to Concentration - Using and Creating Quantities Application Reports

-

Hyaluronic Acid Product Advancements in QC and R&D Application Reports

-

Measurement of sodium hydroxide (NaOH) solutions Application Reports

-

Ocean currents made visible by density measurement Application Reports

Consumables, Accessories, Software & Reference materials

Consumables, Accessories, Software & Reference materials

Accessories & Software

Accessories & Software

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

HOSE 2x4 SILICONE

DMA 4101 | 4501 | 5001

SYRINGE 5 mL LUER (WITHOUT SEAL)

DMA 4101 | 4501 | 5001

CABLE TIE HEAT-RESISTANT 100 pcs

DMA 4101 | 4501 | 5001

ACCESSORY KIT DMA HR01 SERIES/DMA 5000 M

DMA 4101 | 4501 | 5001

PROTECTION CAP, BLACK (SQUARE USB INTERFACE)

DMA 4501 | 5001

Protective cover DMA HR01 series

DMA 4101 | 4501 | 5001

Interface caps DMA HR01 series

DMA 4101 | 4501 | 5001

HOSE 3x5 VITON

DMA 4101 | 4501 | 5001

BOTTLE FOR RINSING LIQUID

DMA 4101 | 4501

GENDER CHANGER DB9F/DB9F

DMA 4101 | 4501 | 5001

"HOSE 300x3x2 PTFE ""AA"""

DMA 4101 | 4501 | 5001

SYRINGE HOLDER 5 ml FOR 5 ml PLASTIC SYRINGE

DMA 4101 | 4501 | 5001

HOSE 3x5 SILICONE

DMA 4101 | 4501 | 5001

HOSE 2x4 VITON

DMA 4101 | 4501 | 5001

ADAPTER LUER 1/4" UNF

DMA 4101 | 4501 | 5001

ADAPTER UNF 1/4"-LUER MALE

DMA 4101 | 4501 | 5001

SYRINGES 2 ml LUER (1000 PCS)

DMA 4101 | 4501 | 5001

INJECTION ADAPTER UNF 1/4"

DMA 4101 | 4501 | 5001

INJECTION ADAPTER LUER

DMA 4101 | 4501 | 5001

INJECTION ADAPTER FITTING WITH METAL TUBE

DMA 4101 | 4501 | 5001

SYRINGES 5 ml LUER (100 pcs.)

DMA 4101 | 4501 | 5001

MALE LUER PLUG

DMA 4101 | 4501 | 5001

ADAPTER LUER CONE

DMA 4101 | 4501 | 5001

SYRINGE 2 ml LUER (1 PCS)

DMA 4101 | 4501 | 5001

PRINTER PAPER 57x30 STANDARD

DMA 4101 | 4501 | 5001

DENSITY STANDARD SODIUM BROMIDE

DMA 4101 | 4501 | 5001

HOSE 4X6 SILICONE

DMA 4101 | 4501 | 5001

SYRINGES 2 ml LUER (10 PCS)

DMA 4101 | 4501 | 5001

PRINTER PAPER FOR EPSON TM-U220

DMA 4101 | 4501 | 5001

RIBBON CARTRIDGE FOR EPSON PRINTER TM-U220

DMA 4101 | 4501 | 5001

COLOR ADJUSTMENT SET 3x ULTRA-PURE WATER 2x color standards (50 ml).

DMA 4101 | 4501 | 5001

HOSE CLAMP DMIN 5.8 DMAX 6.5

DMA 4101 | 4501 | 5001

SYRINGES 5 mL LUER-LOCK (100 PCS)

DMA 4101 | 4501 | 5001

SYRINGE 10 mL LUER-LOCK

DMA 4101 | 4501 | 5001

INJECTION ADAPTER LUER-LOCK

DMA 4101 | 4501 | 5001

INTERFACE CABLE DMA™-PC 9-POLE MALE / 9-POLE FEMALE

DMA 4101 | 4501 | 5001

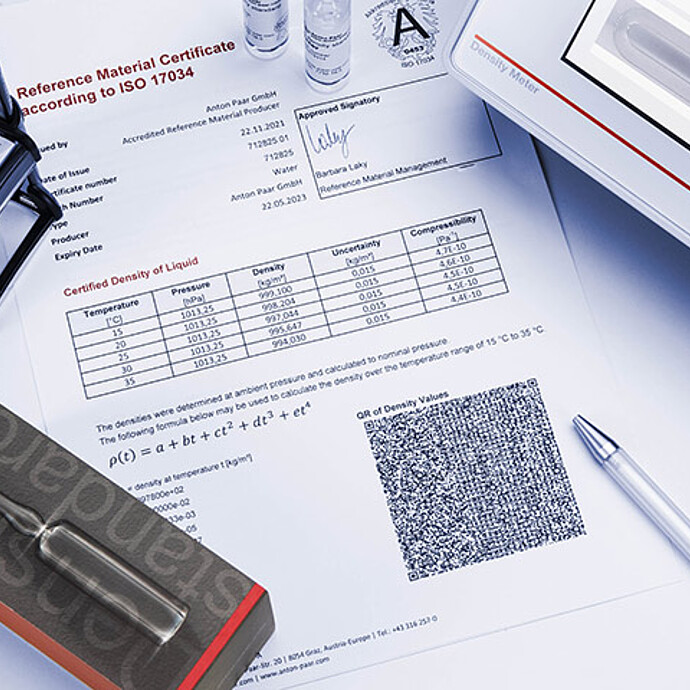

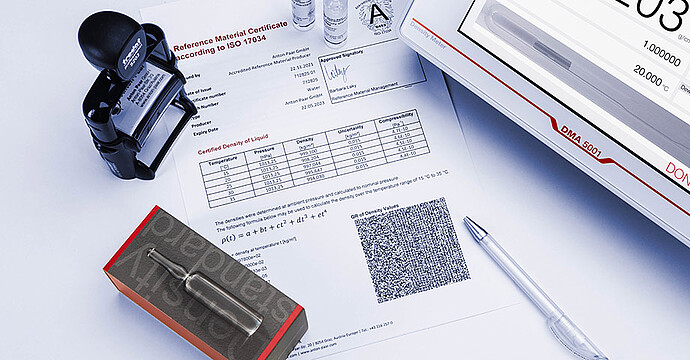

ISO 17034-Certified Reference Material:

Density Standards

DMA 4101 | 4501 | 5001

- Market-leading uncertainty of 0.015 kg/m³ (ISO 17034)

- Application-specific density standards, available via webshop

- Online certificate with lifetime reference values guarantee

- Conformity with ISO requirements ISO 17025 and even ISO 17034

- Safety glass ampoule for zero contamination

DRYING CARTRIDGE

DMA 4101 | 4501 | 5001

Sample Changer:

Xsample 520

DMA 4101 | 4501 | 5001

- The multi-sample changer that provides first-class filling at a snap

- Handles up to 96 samples in one magazine

- Ideal for beer, wine, soft drinks, syrups, and other aqueous samples which can be replaced without intermediate cleaning

- Multiple fillings from the same vial if required

KEYBOARD USA USB

DMA 4101 | 4501 | 5001

Sample Changer:

Xsample 330

DMA 4101 | 4501 | 5001

- The single sample changer for a wide range of samples

- Prevents sample carry-over with automatic rinsing and drying after each sample

- Highly resistant wetted parts for handling aggressive samples

KEYBOARD GERMAN USB

DMA 4101 | 4501 | 5001

Sample Changer:

Xsample 320

DMA 4101 | 4501 | 5001

- The single sample changer for easy operation

- Multiple fillings from the same vial if required

- Highly resistant wetted parts for handling of aggressive samples

- Quick replacement of the sample without intermediate cleaning

Sample Changer:

Xsample 340

DMA 4101 | 4501 | 5001

- The single sample changer for different syringe sizes

- The robust solution for reliable and repeatable results

- Prevents sample carry-over with automatic rinsing and drying after each sample

- Highly resistant wetted parts for handling aggressive samples

PROTECTING COVER FOR KEYBOARD

DMA 4101 | 4501 | 5001

Sample Changer:

Xsample 530

DMA 4101 | 4501 | 5001

- The multi-sample changer with the highest cleaning performance

- Handles up to 71 samples with optional sample recovery

- Automated cleaning and drying with up to three solvents

- Customized magazines available for your own vials

- Measurement of volatile samples

PRINTER EPSON TM-U220D or B

DMA 4101 | 4501 | 5001

HEATING ATTACHMENT FOR DMA HR01 / M SERIES

DMA 4101 | 4501 | 5001

Lab Execution Software:

AP Connect Start

DMA 4101 | 4501 | 5001

- Now: 100 % discount at checkout!

- Kickstart your paperless lab

- Featuring key benefits of the Standard edition

- Restricted to one instrument, single user access, one export rule

Lab Execution Software:

AP Connect Pharma one-time license

DMA 4101 | 4501 | 5001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Standard one-time license

DMA 4101 | 4501 | 5001

- One-time fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Pharma subscription license

DMA 4101 | 4501 | 5001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Assurance of lab data integrity

- Fast decisions: data at your fingertips

Lab Execution Software:

AP Connect Standard subscription license

DMA 4101 | 4501 | 5001

- Annual fee per instrument

- Time-saving processes: automatic, digital data transfer

- Top data quality: elimination of transcription errors

- Fast decisions: data at your fingertips

AP DENSITY STANDARD DODECANE 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 4101 | 4501 | 5001

- Density standard with low density (750 kg/m³)

- Organic liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD SODIUM BROMIDE 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 4101 | 4501 | 5001

- Density standard with high density (1250 kg/m3)

- Aqueous liquid

- Measuring uncertainty: 0.03 kg/m³

- Specified temperature range: 15 °C – 25 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD GLUCOSE / WATER 10% 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 4101 | 4501 | 5001

- Density standard with medium density (1040 kg/m3)

- Aqueous liquid

- Measuring uncertainty: 0.02 kg/m³

- Specified temperature range: 15 °C – 25 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD WATER 1x10 mL WITH ISO 17034 CERTIFICATE

DMA 4101 | 4501 | 5001

- Density standard with medium density (998 kg/m3)

- Aqueous liquid

- Suitable for density adjustments

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 35 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

AP DENSITY STANDARD OIL 30 cSt @ 40 °C 1x10 mL, WITH ISO 17034 CERTIFICATE

DMA 4101 | 4501 | 5001

- Density standard with low density (830 kg/m3)

- Organic liquid

- Viscous liquid

- Measuring uncertainty: 0.015 kg/m³

- Specified temperature range: 15 °C – 50 °C

- Durability: 18 months

- Volume: 10 mL

- ISO 17034-certified reference material

- Complies with ISO 17025 and ISO 17034 requirements

DENSITY STANDARD TRIMETHYLPENTANE

DMA 4101 | 4501 | 5001

DENSITY STANDARD LUBE OIL LARGO 8cSt@40°C

DMA 4101 | 4501 | 5001

DENSITY STANDARD ETHANOL IN WATER 40%ABV

DMA 4101 | 4501 | 5001

DENSITY STANDARD ETHANOL IN WATER 9%ABV

DMA 4101 | 4501 | 5001

DENSITY STANDARD DEXTROSE IN WATER 10%W/W

DMA 4101 | 4501 | 5001

DENSITY STANDARD "CAESIUM CHLORIDE" 10ML

DMA 4101 | 4501 | 5001