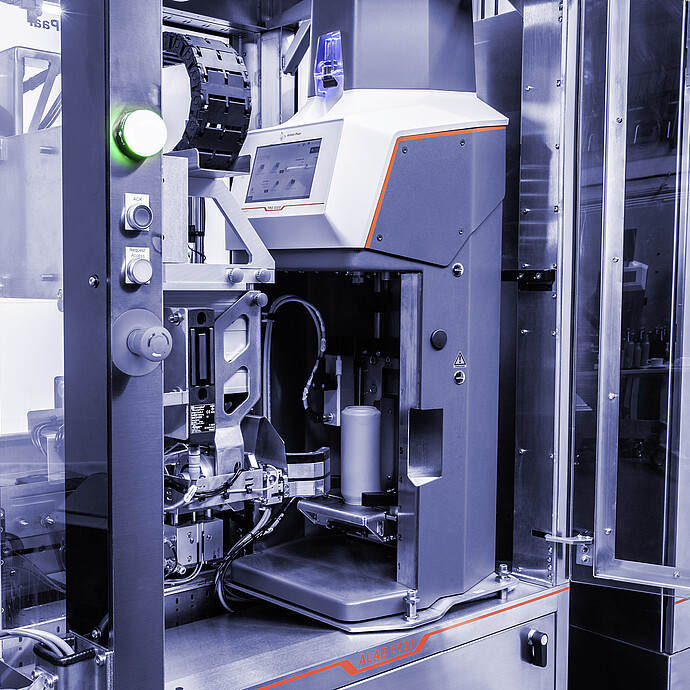

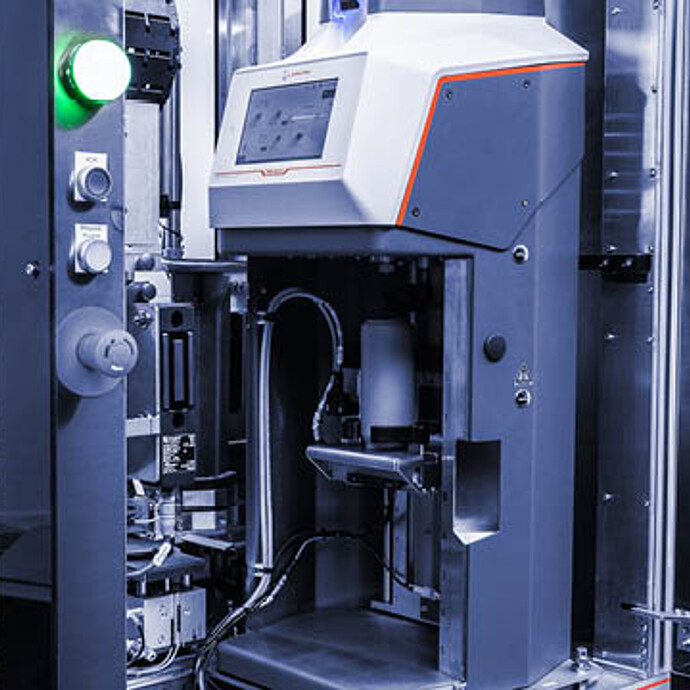

The Automated Lab for the Beverage Industry:

ALAB 5000

- Real-time, at-line measurement results of important QC parameters

- No manual sample preparation

- Fully automated, 24/7 operation means no downtime and maximum productivity

- Designed to perform in rough production environments

Designed for filling lines and analysis labs, the ALAB 5000 series brings automated quality control to the beverage industry. We’ve integrated our instruments for packaged beverages into an automated solution that provides quick, at-line quality control for various beverages, including beer, wine, soft drinks, water, and sake.

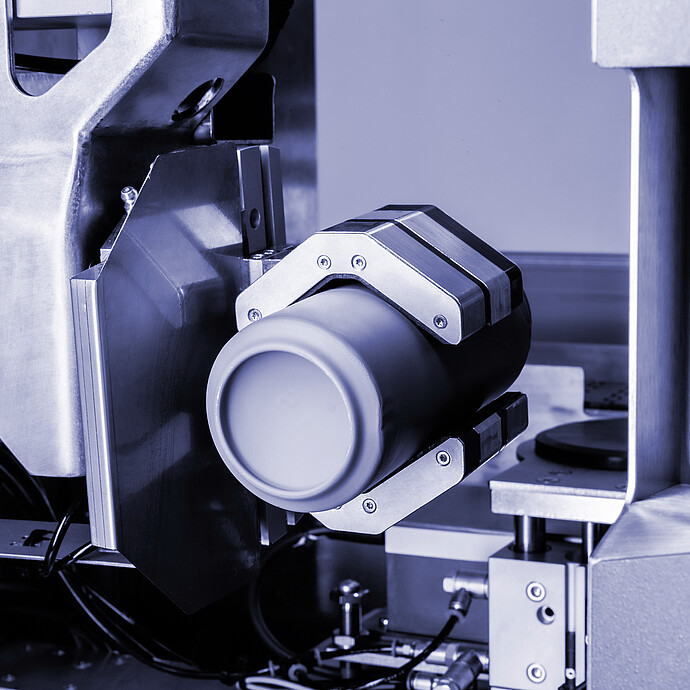

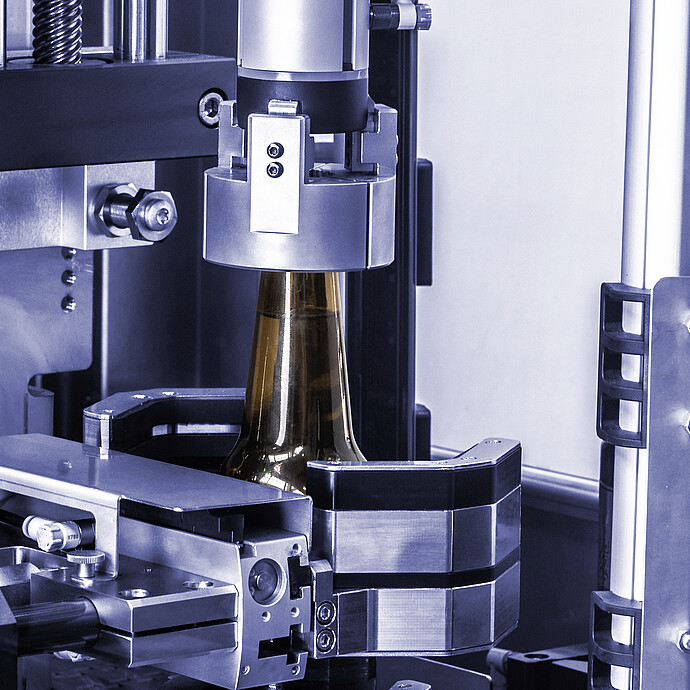

ALAB 5000 Analytic can analyze bulk and retail packaged beverages for the most important physical and chemical parameters, while ALAB 5000 Torque measures the opening torque of twist-off caps and crowns for bottles. Integrate ALAB 5000 Analytic or ALAB 5000 Torque into new or existing filling lines, or use them as stand-alone solutions. And since you’re working with one company for your whole measuring system, know your instruments and systems are seamlessly compatible.

Key features

Automated, real-time measurement results

Automated, 24/7 operation means no downtime on your production line and maximum productivity. Real-time measurement results right at the production line mean your production team can respond to deviations on the spot, saving you future costs on out-of-spec production. Since anyone on your production team can respond to any deviations, there's no need to get your highly trained QC team involved.

Eliminate errors, no sample prep needed: Because sample preparation is automated, each sample is prepared in a reproducible, accurate way. Every measurement starts with the same external influences – and there’s no operator influence – which ensures high reproducibility of measurement results.

Enhanced throughput and time savings

We've combined decades of experience in the beverage industry with a proven design to produce an automated measuring system that you can rely on. Eight-minute (Analytic) and 30-second (Torque) measurement times and at-line analysis let you conduct more measurements than ever before. Automated cleaning and maintenance features (and integrated analytics) let your production team focus on other, more pressing tasks during the day.

One instrument, one sample, tons of parameters

With ALAB 5000 Analytic, measure your most relevant parameters on one sample and spend your time working on more important tasks. With our total package oxygen meter TPO 5000 and our Packaged Beverage Analyzer (PBA) system, you can determine important parameters such as density, alcohol concentration, extract, and many more depending on the configuration.

One solution for wide range of bottle sizes and diameters

With its universal adapter for closure diameters, ALAB Torque can measure the opening torque and ring crack torque of cap diameters ranging from 25 mm to 40 mm, no matter the material. With an automatic torque verification, you know you always get correct measurement results.

Robust and ready for the production facility

Protective features – like housing and enclosed cabinets – let it withstand high temperatures and humidity levels. With air conditioning and a dry air supply, it maintains stable ambient conditions so you can move your instruments from your lab to your production line.

Technical specifications

| ALAB 5000 Analytic | ||

| Measuring range | Trace range sensor | Wide range sensor |

| Oxygen in the gas phase | 0 hPa to 45 hPa | 0 hPa to 1000 hPa |

| Dissolved oxygen | 0 ppm to 2 ppm | 0 ppm to 45 ppm |

| Temperature [1] | 0 °C to 40°C (32 °F to 104 °F) for non-frozen samples (TPO-only); 15 °C to 20 °C (59 °F to 68 °F) | |

| Pressure | 5 bar to 6.2 bar abs. | |

| Density | 0 g/cm³ to 3 g/cm³ | |

| Alcohol (optional) | 0 % v/v to 12 % v/v | |

| Original extract (optional) | 0 °Plato to 30 °Plato | |

| Color (optional) | 0 EBC to 120 EBC | |

| CO2 concentration | 0 Vol. to 5.5 Vol. at 35 °C, 0 Vol. to 10 Vol. at < 10 °C | |

| Turbidity (optional) | 0 EBC to 100 EBC / 0 NTU to 400 NTU | |

| pH value (optional) | pH 0 to pH 14 | |

| Repeatability s.d. | ||

| Density | 0.000001 g/cm³ | |

| Temperature | 0.001 °C (0.002 °F) | |

| Alcohol (optional) | 0.01 % v/v | |

| Original extract (optional) | 0.03 °Plato | |

| Extract (optional) | 0.01 % w/w | |

| Color (optional) | 0.1 EBC | |

| CO2 concentration | 0.005 vol. (0.01 g/l) | |

| TPO concentration [2] | ± 8 ppb or ± 6%, whichever is higher | ± 25 ppb or ± 6%, whichever is higher |

| Turbidity (optional) | 0.02 EBC / 0.08 NTU | |

| pH value (optional) | 0.02 (in the range pH 3 to pH 7) | |

| Typical measurement time per sample | 8 min | |

| Environmental conditions | ||

| Ambient temperature | 2 °C to 49 °C | |

| Relative humidity (not condensing) | at 2 °C to 35 °C: 0 % - 90 % at > 35 °C: 0 % - 50 % | |

| Package dimensions | ||

| Package diameter | 55 mm to 95 mm | |

| Package height | 80 mm to 300 mm | |

| Package volume [3] | 150 ml to 2,000 ml | |

| Tested packages and sample types [4] | ||

| Glass (without cork) | 7 oz, 12 oz, 18 oz, 22 oz, 40 oz; 330 ml, 400 ml, 500 ml | |

| Aluminum bottle | 16 oz | |

| Aluminum can | 8 oz, 10 oz, 12 oz, 16 oz, 24 oz; 330 ml, 350 ml, 500 ml | |

| Typical sample types | All non-pulp-containing common styles of beer, seltzer, and water. | |

| Further details | ||

| Nitrogen | Class 5.0 (99.999 %) 8 bar to 11 bar abs. | |

| Pressurized air | 5.5 bar to 11 bar abs., oil-free | |

| Water | 2 bar to 7 bar abs., chlorine-free | |

| Communication interfaces | 2 x USB, Ethernet | |

| Power supply | AC 200 V to 240 V; 45 Hz to 66 Hz, max. 3.6 kW | |

| Dimensions TPO housing (L x W x H) | 1750 mm x 880 mm x 2430 mm | |

| Weight TPO housing | Approx. 670 kg (1477 lbs) | |

| Dimensions PBA housing (L x W x H) | 560 mm x 950 mm x 2110 mm | |

| Weight PBA housing | Approx. 230 kg (507 lbs) | |

| Altidude | Max. 2000 m (max. 6560 ft) | |

| Display | 19" Multi-Touch Industrial-PC 1920 px x 1080 px | |

| Controls | Touchscreen | |

[1] 35 °C (95 °F) for carbonization levels >5.5 g/L, 10 °C (50 °F) for carbonization levels >10 g/l.

[2] At ambient and sample temperature of 23 °C (73.4 °F) and if standard cleaning is applied. Please note that the first measurement of a set is not considered for the determination of the repeatability of the set.

[3] For TPO only, > 260 ml for TPO and PBA.

[4] Approval for other package types on request. Approval for other sample types on request.

| ALAB 5000 Torque | |

| Measuring range | |

| Measuring area | 0 Nm to 2 Nm |

| Typical measuring time | 30 s |

| Environmental conditions | |

| Ambient temperature | 2 °C to 49 °C |

| Relative humidity (not condensing) | at 2 °C to 35 °C: 0 % - 90 % at > 35 °C: 0 % - 50 % |

| Package dimensions | |

| Package diameter | 55 mm to 95 mm |

| Package height | 80 mm to 300 mm |

| Cap diameter | 25 mm to 40 mm |

| Tested packages and sample types [1] | |

| Glass (without cork) | 7 oz, 12 oz, 18 oz, 22 oz, 40 oz; 330 ml |

| Aluminum bottle | 16 oz |

| PET | 500 ml |

| Further details | |

| Pressurized air | 5.5 bar to 11 bar abs., oil-free |

| Communication interfaces | 2 x USB, Ethernet |

| Power supply | AC 200 V to 240 V; 45 Hz to 66 Hz, max. 1.0 kVA |

| Dimensions ALAB 5000 Torque (L x W x H) | 1750 mm x 880 mm x 2430 mm |

| Weight ALAB 5000 Torque | Approx. 550 kg (1213 lbs) |

| Altitude | Max. 2000 m (max. 6560 ft) |

| Display | 19" Multi-Touch Industrial PC 1920 x 1080 px |

| Controls | Touchscreen |

[1] Approval for other package types on request. Approval for other sample types on request.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Brochure ALAB 5000 Brochures