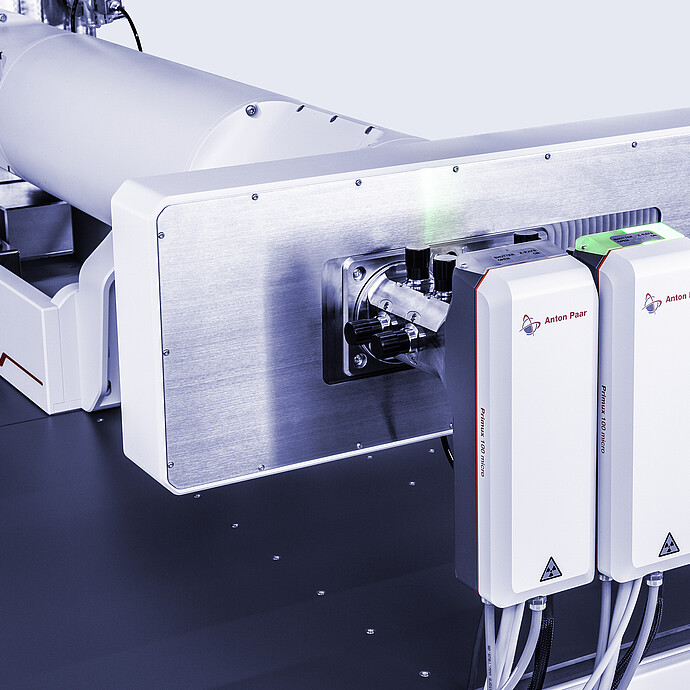

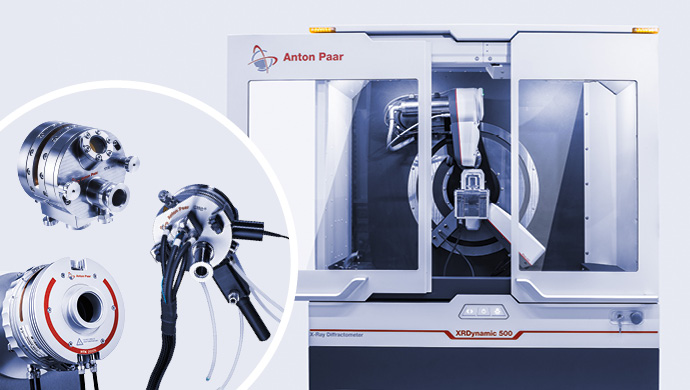

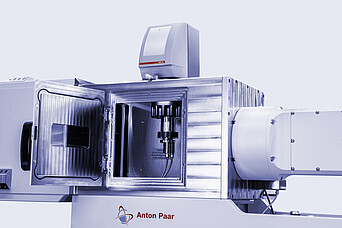

SAXS/WAXS/GISAXS/USAXS/RheoSAXS Laboratory Beamline:

SAXSpoint 5.0

- Compact 3.6 m x 0.9 m footprint

- Investigate nanomaterials (e.g., size, shape, internal structure)

- Non-destructive measurement technology

- Measure samples directly in their native biological environment

- Optimize measurements for the synchrotron

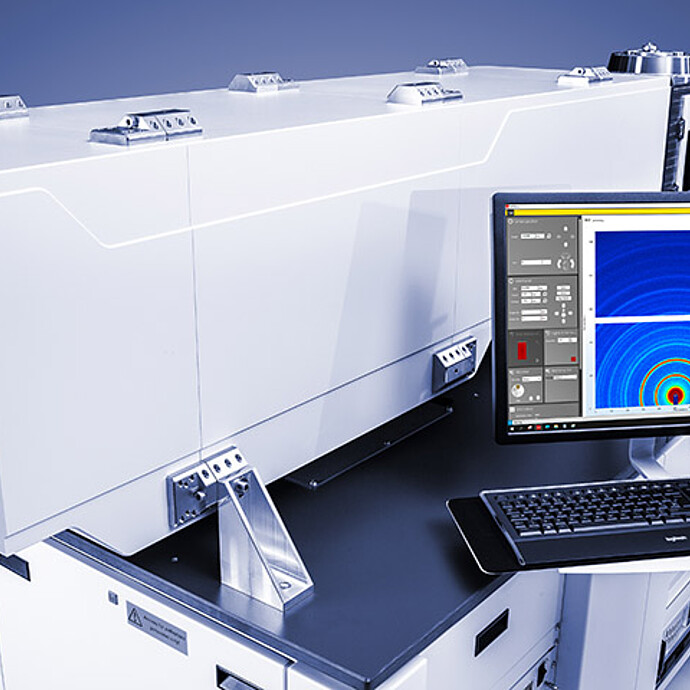

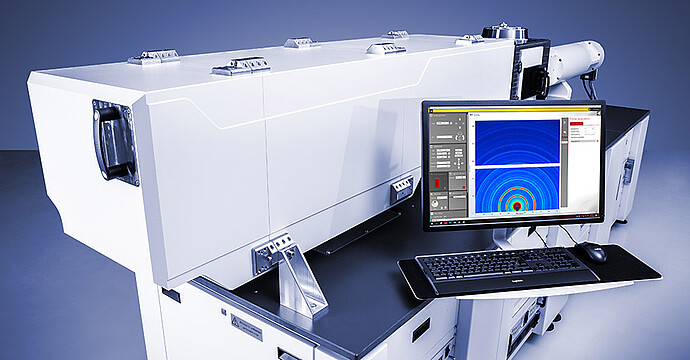

SAXSpoint 5.0 is the ultimate SAXS/WAXS/GISAXS/USAXS/RheoSAXS laboratory beamline with synchrotron detector technology for the highest resolution in a compact system. Anton Paar’s brilliant SAXS system resolves nanostructures up to 620 nm. SAXSpoint 5.0 offers flexible analysis of almost any material under ambient and non-ambient conditions. A number of additional optional features equip SAXSpoint 5.0 for future applications up to the micrometer range (USAXS). Easily perform non-destructive investigations of material properties via powerful software packages that enable automatic operation and data analysis.

Key features

Excellent data quality with short measurement times

SAXSpoint 5.0 employs a brilliant X-ray beam with high spectral purity and scatterless beam collimation. Equipped with powerful microsource or MetalJet X-ray sources and high-performance optics, it delivers excellent results within exceptionally short exposure times. Combined with the latest hybrid photon-counting (HPC) detectors, it ensures high-quality SAXS/WAXS/GISAXS/USAXS/RheoSAXS results for the analysis of your nanostructured materials. Excellent resolution is reached with this brilliant setup, resolving structures up to 620 nm (USAXS up to the µm range) with the most compact system size (3.6 x 0.9 m) of its class.

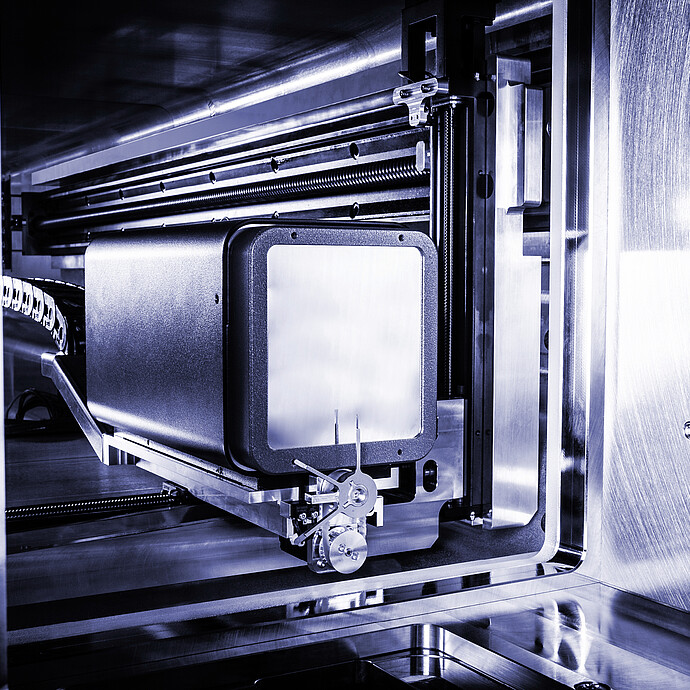

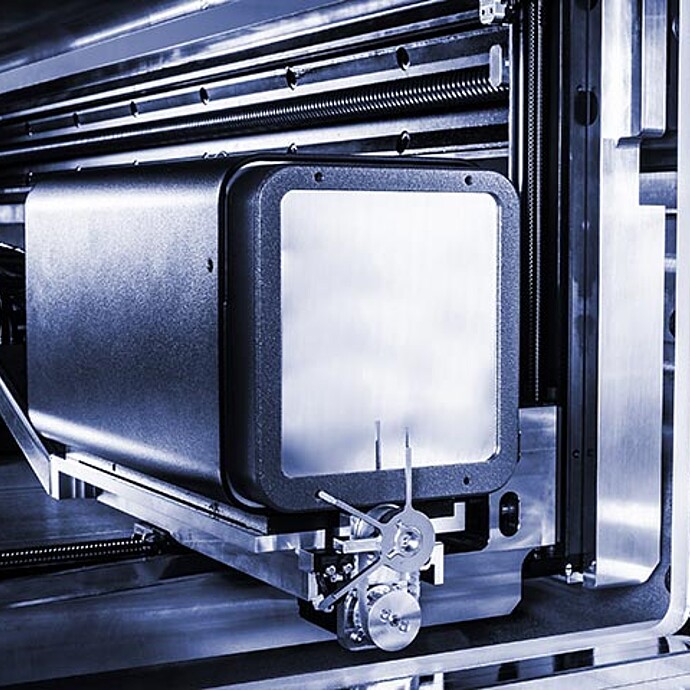

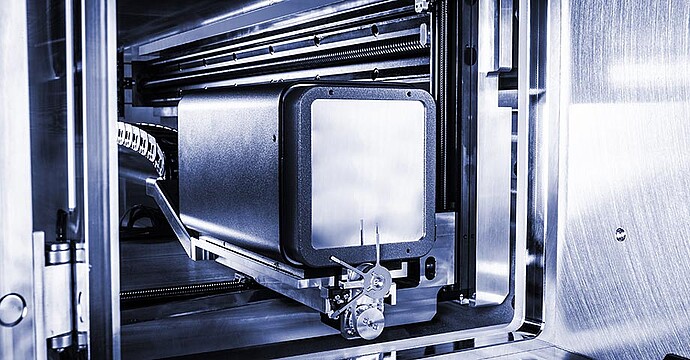

Obtain SAXS and WAXS data in one go

SAXSpoint 5.0 features a moving detector, Slidemaster, which enables completely automatic X-ray scattering studies over a very wide q-range. Obtain SAXS and WAXS data in one go without additional realignment of the system. Choose your optimum q-range from the highest SAXS resolution to a wide WAXS regime for every experiment by just moving the detector.

SAXSpoint 5.0 provides automatic beamstop selection and positioning for your measurement. As it integrates the latest EIGER2 R detectors, windowless and beamstop-less measurements can be performed.

SAXS analysis challenging? Working with SAXSpoint 5.0 isn’t

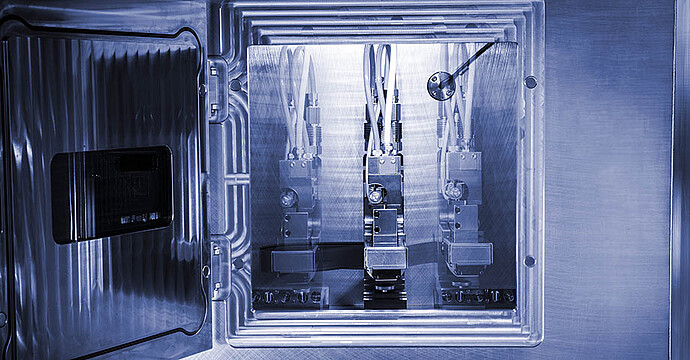

Automating routine tasks to accelerate the way to measurement is standard in the SAXSpoint 5.0 lab system. SAXSpoint 5.0 is equipped with Stagemaster, which automatically aligns all X-ray components and sample stages, recognizes which stage is implemented, and configures the system accordingly. This gives you the best possible result for your measurement setup. Automate your sample throughput with the low-volume autosampler for liquids for up to 192 sample with a temperature-controlled well plate compartment for sample cooling and heating during storage.

Choose stages: One system for all experimental conditions

Almost any nanostructured material can be analyzed with various sample stages from Anton Paar. Switching between different sample stages is easy and fast with TrueFocus, which ensures automatic alignment of all components.

- TCStage sample-holder units: temperature-controlled studies from -150 °C to 600 °C

- Humidity Stage: analysis under defined RH and temperature

- GISAXS/GIXD stage: studies of nanostructured surfaces and thin films

- Heated/cooled sampler: automated studies with temperature-controlled samplers

- Tensile stage: analysis of nanostructured fibers under defined mechanical load

- RheoSAXS module: combined full rheological and nanostructural investigations in one go

Powerful control and data analysis software

SAXS data analysis is complex. The intuitive SAXSdrive™ and SAXSanalysis™ software solutions are the easiest way to obtain results. They support automated routine steps, like measurement setup and alignment, and comprehensive data analysis. Set up serial measurements, benefit from automated sampling, temperature scans, and time-dependent studies, and analyze your 1D and 2D data sets using customizable templates. Determination of parameters like radius of gyration (RG), particle size, Porod constant, specific surface, Kratky plot, etc. is standard in SAXSanalysis™.

Technical specifications

| X-ray source |

|

| X-ray optics and collimation |

|

| Sample stages and autosamplers |

Customized solutions available on request |

| Special features | Slidemaster: moving detector (translation in X,Y,Z) |

| Temperature range | -150 °C to +600 °C |

| Temperature accuracy | ±0.1 °C |

| Atmosphere | Vacuum, air, inert gas, humidity (reactive gases on request) |

| Sample holders |

Customized solutions available on request please contact us |

| Detectors | 2D EIGER2 R and PILATUS3 R series HPC detectors High-resolution WAXS module (EIGER2 R series) |

| Accessible q-range | 0.01 nm-1 to 49.3 nm-1 (main detector) |

| Software |

|

| Footprint |

|

Standards

ISO

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

An Insight into the Structure of Copolymer Surfactants Application Reports

-

An Insight into the Structure of Surfactants Application Reports

-

Characterization of Fibrous Materials with SAXS Application Reports

-

Characterizing the Nanostructure of mRNA Vaccines by Small-angle Scattering Application Reports

-

Coir Fibers - SWAXS Studies of Structural Changes Induced by Tensile Stress Application Reports

-

Combined Rheo-SAXS Investigations using a Laboratory SAXS System Application Reports

-

Continuous SWAXS Data Studies with the EIGER2 R 500K WAXS Module Application Reports

-

Evaluating GISAXS Data with SAXSanalysis Using the BornAgain Export Application Reports

-

Fast SAXS Studies of Sensitive Biological Samples Application Reports

-

GISAXS as a Valuable Tool for Analyzing Nanostructured Semiconductors Application Reports

-

In-line SEC-SAXS of HSA Protein Using a Laboratory SAXS Instrument Application Reports

-

In-situ GISAXS heating experiments on self-assembled Gold nanoparticles Application Reports

Consumables & Accessories

Consumables & Accessories

Accessories

Accessories

If you do not find the item you require, please contact your Anton Paar sales representative.

To find out if you can purchase online from your location, check the online availability below.

QUARTZ CUVETTE 1 mm FOR TCS Sample holder with 1 mm quartz capillary for measurements of

Temperature-Controlled Sample Stages:

TCStage

- Temperature-controlled sample stages for single samples

- Dedicated sample holders for liquids, solids, pastes, and gels

- Special sample holders e.g. for sample spinning, under pressure, and for disposable capillaries

- Temperature range from -150 °C to +600 °C

Heated Sampler

- Temperature-controlled sample stages for Anton Paar’s SAXSpoint systems

- Automatic scans on up to 20 solid, liquid, and paste/gel-like samples

- Heated/Cooled Sampler: from -10 °C to 120 °C

- Heated Sampler 2.0: from -150 °C to 350 °C

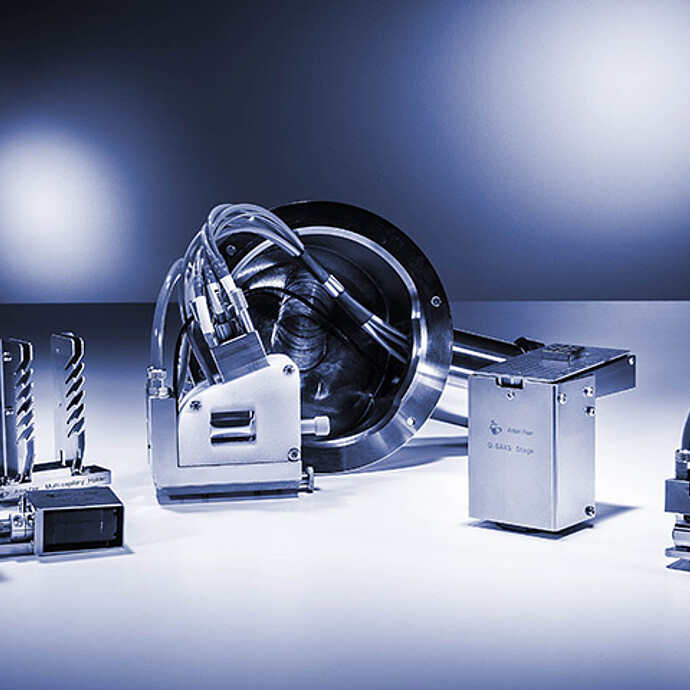

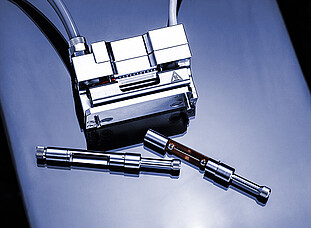

Bonse-Hart USAXS Camera:

USAXS Module

- Automatic USAXS, SAXS, and WAXS studies using a fully motorized experimental setup

- Probing structures from the nanometer to the micrometer level

- Simultaneous and precise (± 0.1 °C) sample temperature control

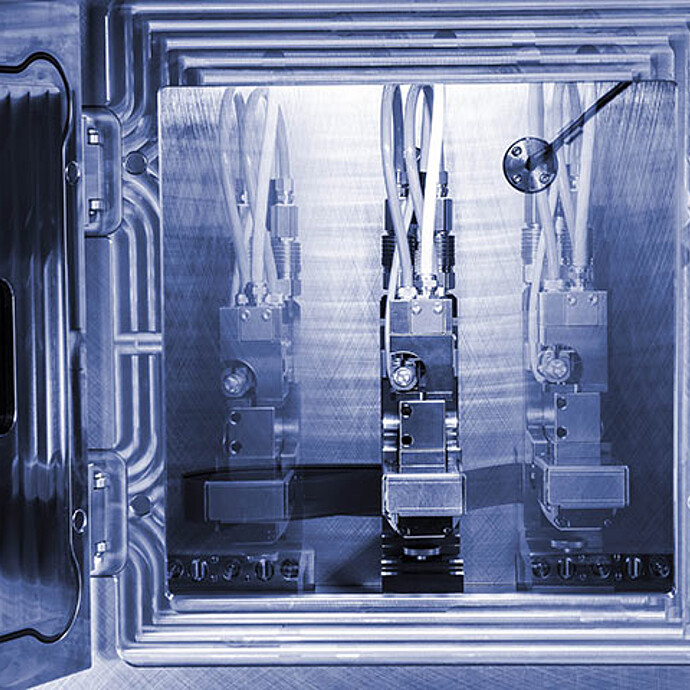

(Bio-)SAXS Autosampler for Liquids:

Low-Volume Autosampler

- High-throughput autosampler for liquid nanoparticle and biological samples (up to 192 in one run)

- Optimized setup requiring minimal sample volume (≤ 5 μL)

- Modular design enabling easy switch-over to standard SAXS sample stages

Autosampler:

ASX

GISAXS Stage 2.0

- Investigation of nanostructured surfaces and thin film samples

- Ideal for mesoporous thin films, surface-deposited nanoparticles, metal deposits on oxide surfaces, soft matter systems, and biological materials attached to surfaces

- Samples can be tilted and rotated

Tensile Stage 2.0

- The only commercially available stage specially designed for in-situ SWAXS studies of stress/strain phenomena

- For investigating fibers, foils, and thin films

- Studies at forces between 0.01 N and 600 N

- Temperature range from -150 °C to +350 °C

Humidity Stage

- For temperature- and humidity-dependent SAXS and WAXS studies of nanostructures

- Ideal for investigating the influence of temperature and humidity on powders and thin films

- Studies in vacuum, air, and inert gas from 10 °C up to 110 °C

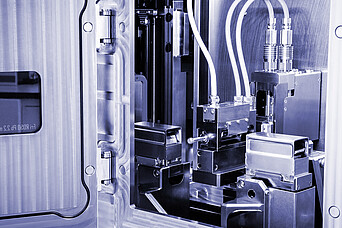

Combined Rheology and SAXS Setup:

RheoSAXS Module

- Study structural and rheological properties simultaneously

- Measure parallel or perpendicular to flow direction

- All existing SAXSpoint instruments can be upgraded with this module