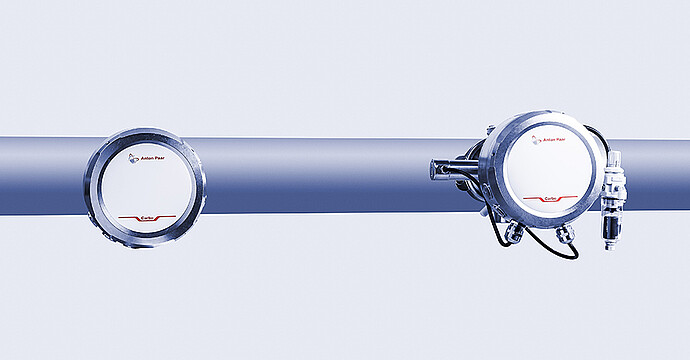

Inline CO₂ Sensor:

Carbo

- Suitable for beverages that also contain pulp

- Well-established measuring technology with the highest accuracy and reliability

- Long service intervals and very easy maintenance, ensuring minimum downtimes in production

- Constructed according to EHEDG guidelines

Anton Paar’s CO₂ sensors continuously deliver true CO₂ values for any beverage, at an outstanding total cost of ownership. Carbo 6100 and Carbo 6300 are maintenance-free and EHEDG-certified. Beyond process monitoring, the 4-second measuring interval permits reliable and stable closed-loop control of the carbonators. Carbo 5100 uses proven, reliable, super-accurate measuring technology and requires only once-a-year maintenance. Additionally, the newly developed technology, combining Carbo 6X00 and Carbo 5100, allows operators to measure foreign gases like nitrogen or nitrous oxide in their carbonated samples.

Key features

Zero maintenance: Save time and money with the Carbo 6X00 series

Save on running expenses and get the lowest total costs of ownership (TCO): While conventional CO₂ sensors can multiply their price over an entire service life due to recurring maintenance, Carbo 6100 and Carbo 6300 are completely maintenance-free:

- No moving parts with wear to exchange

- Self-diagnosis according to NAMUR NE 107

Carbo 5100 requires service only once per year when operating 24/7. By using the optional cut-off adapter it can be removed from the product line without time-consuming and expensive production stops.

Suitable for all beverages: Be flexible with your beverage types

The Carbo sensors can deal with any beverage, even with those containing fruit fibers or pulp. Carbo 5100 and Carbo 6100 start measuring right after a fast selection of the proper product type. Carbo 6300 has an additional unique and patented* measuring channel to detect the beverage type. No matter whether carbonated soft drinks, beer, wine, or sparkling water, Carbo 6300 makes your product changes easier.

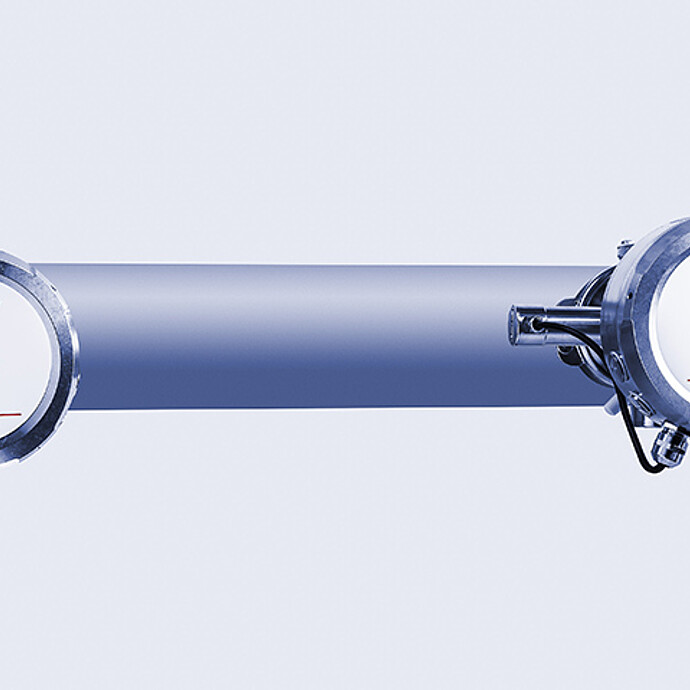

Your best fit: Easy integration and automation in the process

The new-generation CO₂ sensors can be installed inline or in a bypass or tank, according to your needs. They are easily integrated into your workflow using the touchscreen interface of the built-in evaluation unit, via the Pico 3000 software, or with the help of the mPDS 5 evaluation unit.

The sensors can be adapted to support several communications protocols such as: analog (4 mA to 20 mA), Modbus RTU, Modbus TCP, HART, PROFIBUS DP, PROFINET IO, and EtherNet/IP.

Fast and reliable results whatever the conditions

Carbo 5100 is designed following EHEDG guidelines and its proven measurement principle delivers correct results at any time. The optical sensors Carbo 6100 and Carbo 6300 use a patented* technology that eliminates the risks of incorrect measurements, e.g. after hot cleaning (CIP). The Carbo 6X00 series is EHEDG-certified, which reduces the time and effort required during cleaning procedures.

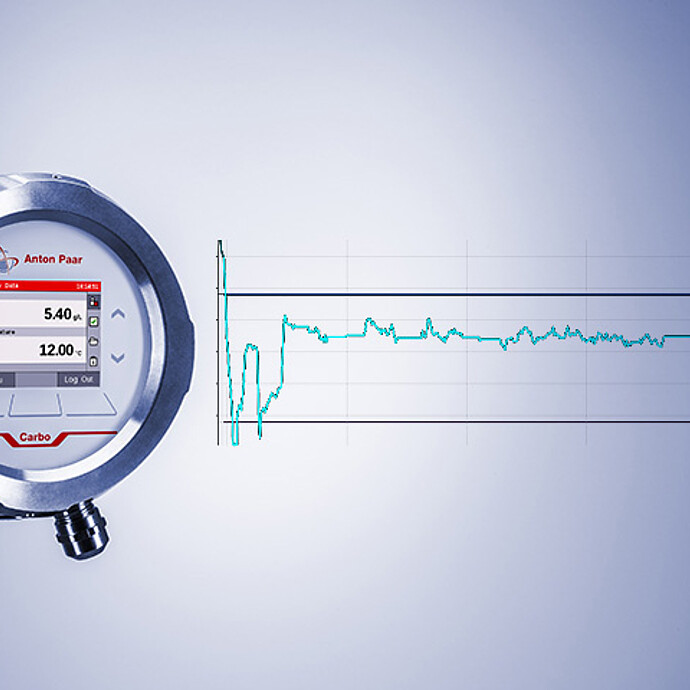

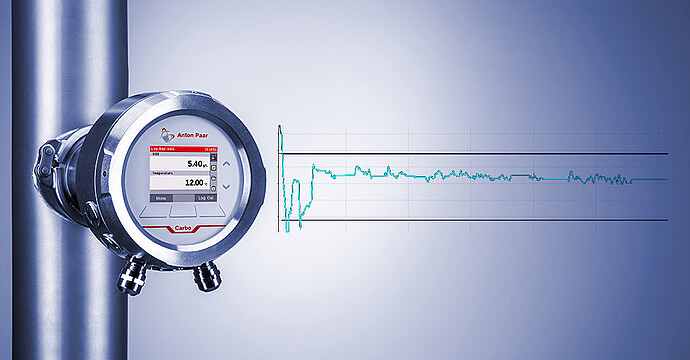

Speed meets excellence: Get your results within seconds

With a measuring interval of only a few seconds, the sensors of the Carbo series are known as the fastest CO₂ sensors on the market, also suitable for closed-loop control of carbonators. With Carbo 5100 and Carbo 6X00 you always know the actual CO₂ concentration of all beverages in your process, with the highest accuracy and repeatability even under start/stop conditions. The optical sensors deliver correct measurements even during long flow stops, directly in the production line.

Foreign gas measurement

Anton Paar offers two inline options to measure CO₂ in carbonated beverages: sensors applying traditional manometric determination or optical measuring principles. For additional dissolved gases, such as nitrogen in beer or nitrous oxide in sugared soft drinks, a combination of both measuring principles is applied to optimize results for each gas component. Decades of inline beverage analysis experience meet cutting-edge technology in this newly developed measurement technique. In the case of nitrous oxide, this is the only available method on the market.

Technical specifications

| Carbo 5100 | Carbo 6100 | Carbo 6300 | |

|---|---|---|---|

| Application | CO₂ measurement | ||

| Measuring range | 0 to 20 g/L (0 to 10 vol) | 0 to 12 g/L (0 to 6 vol) | |

| Accuracy* | 0.05 g/L (0.025 vol) | 0.05 g/L (0.025 vol) | |

| Repeatability | 0.025 g/L (0.010 vol) | 0.01 g/L (0.005 vol) | |

| Resolution | 0.01 g/L (0.005 vol) | < 0.01 g/L (0.005 vol) | |

| Measuring interval | 15 seconds | 4 seconds | |

| Measuring temp. range | - 5 °C to +40 °C | - 3 °C to + 30 °C | |

| Maximum temperature | +121 °C (max. 30 min) | < +95 °C (max. 4 h) | +130 °C (max. 30 min) |

| Pressure | max. 10 bar rel. (145 psi rel.) | ||

| Compressed air | 4 bar to 7 bar (58 – 102 psi) | - | |

| Self-diagnosis | Compliant with NAMUR NE 107 (self-monitoring and diagnosis) | ||

| Degree of protection | IP 65 and IP 67 | ||

| Process connection | Tuchenhagen Varivent® N | ||

| Certifications | Designed according to EHEDG | EHEDG Type EL Class I | |

| Power Supply | SELV/PELV DC 24 V ± 20 % | ||

| Dimensions (WxHxD) | 224 mm x 224 mm x 235 mm | 142 mm x 142 mm x 220 mm | |

| Weight | approx. 8 kg | approx. 4 kg | |

*product specific adjustment required for Carbo 6100

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Beverage | Beer | Cheers to consistent beer quality: from filter to filler Application Reports

-

Beverage | Beer | Complete your Beer Analysis Application Reports

-

Beverage | Beer | Nitrogenating Beverages with Anton Paar Flex-Blend Application Reports

-

Beverage | Soft Drinks | Complete Your Soft Drink Analysis Application Reports

-

Beverage | Soft Drinks | Online Process Measurement in the Soft Drink Industry Application Reports

-

Beverage | Soft Drinks | The Impact of Sugar Inversion on Soft Drinks with Sugar Application Reports

-

Beverage | Wine | Monitoring Dissolved Carbon Dioxide and Oxygen in Wine Application Reports

-

Process Engineering Solutions | Overview Brochures

-

Sensor monitoring for dynamic propagation protocols Customer Reports and Publications