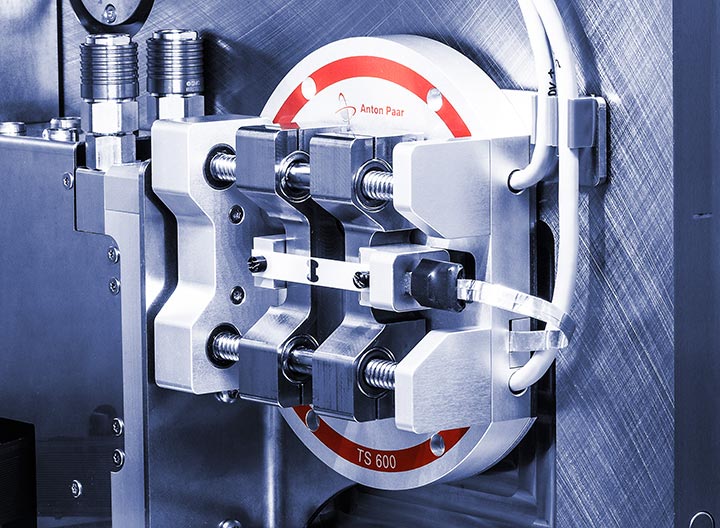

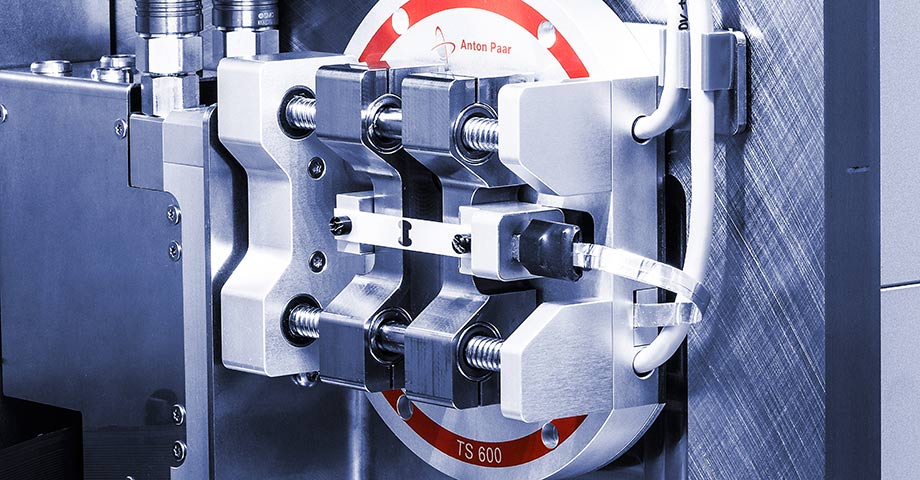

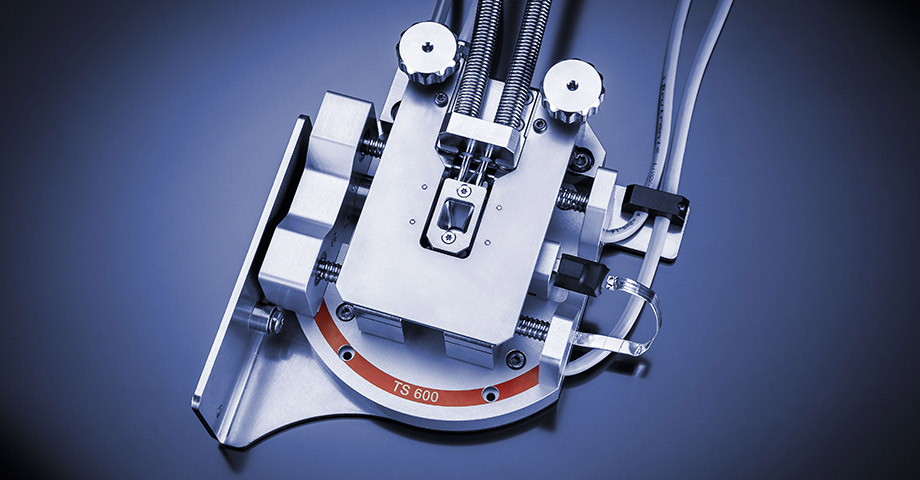

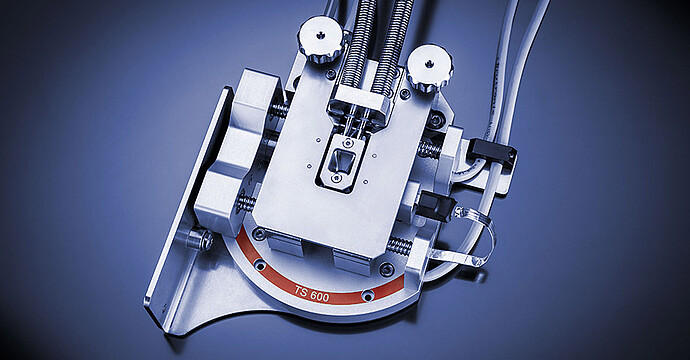

Tensile Stage 2.0

- The only commercially available stage specially designed for in-situ SWAXS studies of stress/strain phenomena

- For investigating fibers, foils, and thin films

- Studies at forces between 0.01 N and 600 N

- Temperature range from -150 °C to +350 °C

The Tensile Stage is the perfect stage for investigating the stress/strain phenomena of fibers, foils, and thin films in both the SAXS and WAXS range. It is equipped with a full-range load cell and a high-resolution load cell. The stress/strain investigations can be performed at ambient conditions and combined with the dedicated Heated/Cryo Module in a temperature range from -150 °C to +350 °C.

Key features

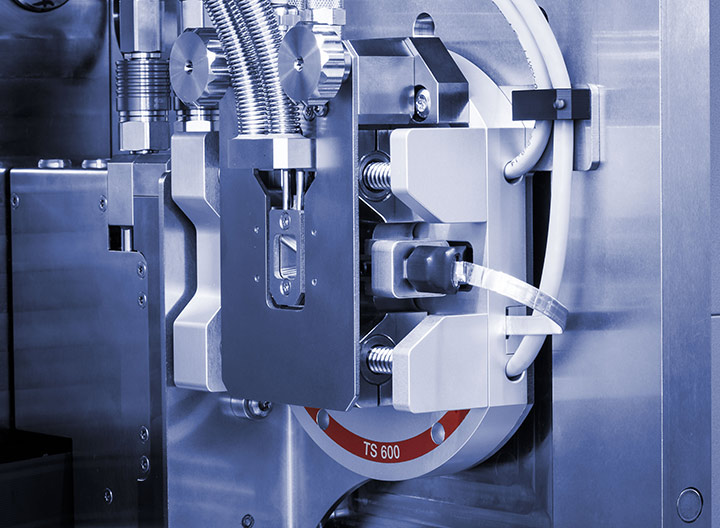

Straining samples at full force and with high resolution

The Tensile Stage enables stress/strain studies at forces between 0.01 N and 600 N. Choose between two load cells:

- The low-range, high-resolution cell for forces from 0.01 N to 5 N

- The full-range cell for forces from 1 N to 600 N

The Tensile Stage includes an easy-to-use software for stage control and data acquisition. You can use it to program complex load profiles.

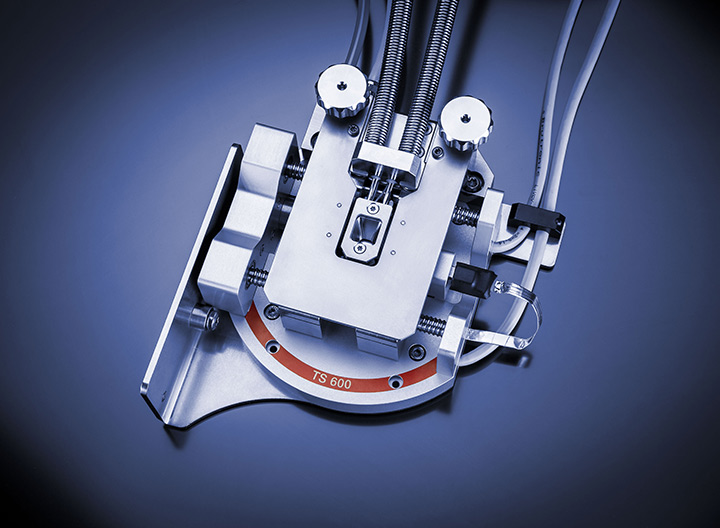

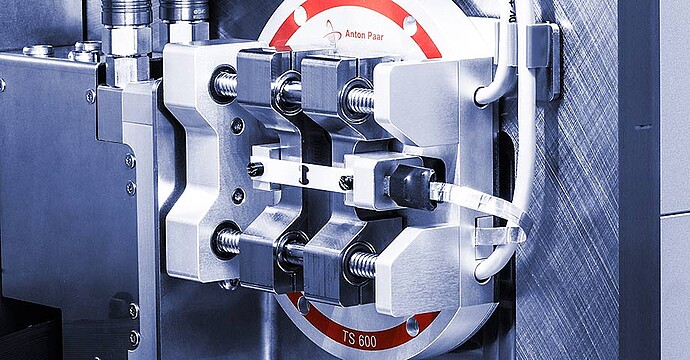

Stress/strain studies from -150 °C to 350 °C

The Tensile Stage has a dedicated Heated/Cryo Module 2.0 for stress/strain studies in a temperature range from -150 °C to 350 °C. The optional Heated/Cryo Module 2.0 is mounted on the Tensile Stage and due to its design maximum temperature homogeneity within the sample is guaranteed. The module is counter-cooled to minimize the temperature impact on the system housing during heating and cooling.

Technical specifications

| Tensile force | 0.01 N to 600 N |

| Temperature range | -150 °C to +350 °C |

| Temperature accuracy | +/-0.1 °C |

Contact us directly for additional information on the latest developments, options, and customized solutions.

Anton Paar Certified Service

- More than 350 manufacturer-certified technical experts worldwide

- Qualified support in your local language

- Protection for your investment throughout its lifecycle

- 3-year warranty

Documents

-

Coir Fibers - SWAXS Studies of Structural Changes Induced by Tensile Stress Application Reports

-

SAXS Sample stages and holders Brochures