The analysis of fuels calls for robust and accurate measurement solutions. Anton Paar’s instruments provide process and laboratory measurements to identify incoming raw material, monitor production processes, or undertake fuel quality testing of final products such as diesel, ethanol, jet fuel, fuel oil, automotive gasoline, kerosene, biofuels, synthetic fuels, bunker oils, and other fuels. Parameters such as density, viscosity, distillation behavior, flash and fire point, rheological behavior, and oxidation stability can be determined by Anton Paar devices according to governmental and environmental regulations such as ASTM, EN, and ISO.

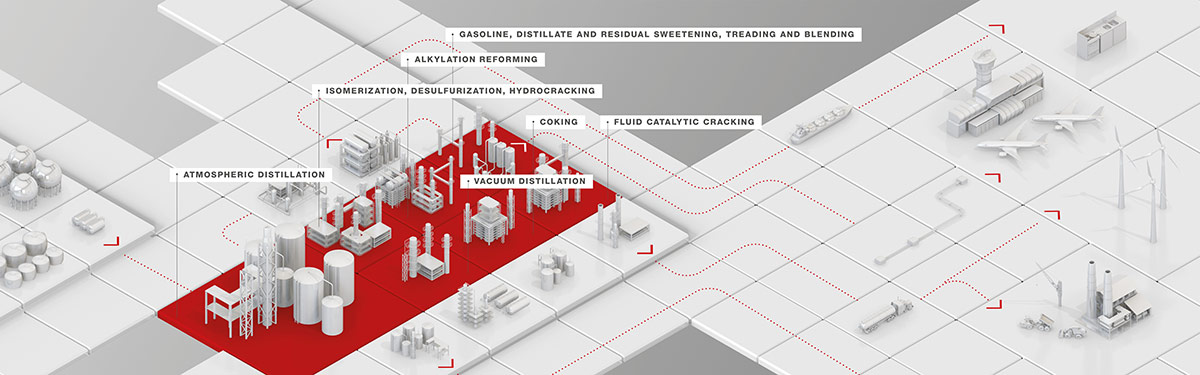

Fuel analysis at refineries

The refinery is at the heart of the downstream process. Here measuring technology can help you ensure that incoming crude oil keeps flowing as it should and that the additives you use have the right composition when delivered. Automated measurements free your lab personnel from repetitive work, increase efficiency, and minimize handling errors. Anton Paar’s instrumentation is on hand to assess the best time to make distillation cuts and to check that the final products meet their specifications. We also offer devices which speed up the time required for preparing samples for elemental analysis with ICP, e.g. for fuel contamination analysis. For research into new and improved products as well as reducing carbon emissions and overall environmental impact, our portfolio has the rheometers, penetrometers, density meters, and pour point testers you need – and much more.

Fuel testing during distribution

Whether you rely on ships, trains, trucks, or pipelines – time is money and you want to keep turnaround times to the absolute minimum and avoid any mistakes during the loading and unloading process. To this end, Anton Paar instruments provide fast and accurate measurements to enable short reaction times and help to minimize the risk of financial losses and delays when switching between batches or different products.

Use Anton Paar’s devices to evaluate whether the distribution of fuel through e.g. multiproduct pipelines has led to impurities. As your petroleum products might be stored for extended periods of time at tank farms and terminals, use one of our portable devices for regular check measurements to make sure there is no (bio-)degradation or contamination. Given the volatile and explosive nature of petroleum products, Anton Paar provides intrinsically safe equipment for such on-site measurements.

We support you with reliable and accurate measuring equipment which performs standardized measurements according to clearly defined test methods so you can fulfill legal regulations and avoid reclamations when trading as well as ensuring correct account settlement.

Simulating the behavior of final products to understand their stability in storage

Fuel analysis for consumers

As a consumer or seller of petroleum products you need to check the quality or specifications of the fuels you buy or trade. Anton Paar has a range of devices for this purpose, including checks on the viscosity, density, gum content, and purity of fuel products. We will help you rise to the challenge of stricter legal regulations regarding emissions and environmental impact and the resulting increase in testing and monitoring of fuels whenever they change hands.

We have the measuring technology you need to keep pace with developments in the automotive sector such as improved biofuels, additive technologies, and electric vehicles. Responding to the trend for using liquefied gases in household cooking and heating we have the testing equipment you need at production and distribution facilities.

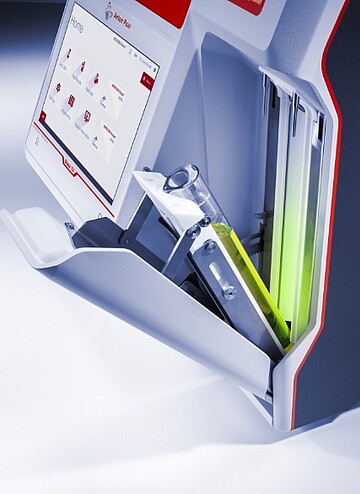

Fuel analysis at testing laboratories

As a testing laboratory you are called on to provide a wide array of analyses: from fuel and diesel oil analysis to fuel quality testing, lube oil testing, and oil-condition monitoring (OCM). Anton Paar’s devices are here to help you achieve high sample throughput and high-accuracy results. We provide automated filling and cleaning for individual measuring instruments or you can choose a completely automated platform with integrated robotics for sample processing on an industrial scale.

Anton Paar is your partner for the utmost reliability of measured data and provides trusted and traceable results protocols.